This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4349732 Ball Bearing is a specialized component designed for use in commercial trucks. It plays a role in ensuring the smooth operation of various mechanical systems within these vehicles. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Ball Bearings

Ball bearings are mechanical components that facilitate the rotation of moving parts by reducing friction between them. They consist of an inner ring, an outer ring, and a series of balls that are held in place by a cage. When one of the rings rotates, the balls roll between the rings, allowing for smooth and efficient motion. Ball bearings are widely used in various mechanical systems, including engines, transmissions, and wheel hubs, due to their ability to handle both radial and axial loads 1.

Purpose of the 4349732 Ball Bearing in Truck Operation

This Cummins part is specifically designed to support the operation of commercial trucks. It is typically placed within the truck’s mechanical system to facilitate the rotation of components such as shafts or axles. By reducing friction, it helps to ensure that these components operate smoothly and efficiently, contributing to the overall performance and reliability of the truck.

Key Features of the 4349732 Ball Bearing

The 4349732 is characterized by several key features that set it apart from other ball bearings. It is constructed from high-quality materials that offer superior durability and resistance to wear. Its design specifications are tailored to meet the demanding requirements of commercial truck applications, ensuring optimal performance under heavy loads and high-speed conditions. Additionally, it may possess unique characteristics such as enhanced lubrication systems or specialized coatings that further improve its functionality and longevity 2.

Benefits of Using the 4349732 Ball Bearing

The use of this part in truck operations offers several advantages. It provides improved performance by ensuring smooth and efficient rotation of mechanical components. Its durable construction contributes to enhanced reliability, reducing the likelihood of unexpected failures. Furthermore, the bearing’s efficient design helps to minimize energy losses, leading to increased fuel efficiency and reduced operational costs 3.

Installation and Integration

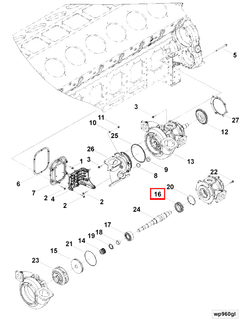

Proper installation and integration of the 4349732 into a truck’s mechanical system are crucial for ensuring optimal performance. It is important to follow manufacturer guidelines and recommendations to ensure that the bearing is correctly positioned and secured. Additionally, attention should be paid to factors such as proper lubrication and alignment to maximize the bearing’s effectiveness and longevity.

Troubleshooting Common Issues

Like any mechanical component, ball bearings may encounter issues over time. Common problems include excessive wear, noise, or vibration during operation. Troubleshooting these issues typically involves inspecting the bearing for signs of damage or misalignment, as well as checking for proper lubrication. In some cases, replacement of the bearing may be necessary to restore optimal performance.

Maintenance and Care

Regular maintenance and care are essential for ensuring the longevity and performance of the 4349732. This includes routine inspections for signs of wear or damage, as well as periodic lubrication to reduce friction and prevent corrosion. Additionally, keeping the bearing clean and free from contaminants can help to prolong its service life and maintain optimal performance.

Performance Metrics

The performance of the 4349732 is measured by several key metrics. These include its load capacity, which indicates the maximum weight it can support, and its speed ratings, which define the maximum rotational speed it can handle. Additionally, the operational lifespan of the bearing is an important consideration, as it determines how long the bearing can be expected to perform reliably under normal operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the commercial truck industry. With a history spanning over a century, Cummins has established a reputation for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrain solutions, and aftermarket parts designed to meet the diverse needs of commercial truck operators 4.

Role of Part 4349732 Ball Bearing in Engine Systems

The 4349732 is integral to the efficient operation of various engine components, particularly in the context of pumps and water systems.

In a Water Pump, the 4349732 facilitates the smooth rotation of the impeller shaft. This bearing reduces friction between the rotating shaft and the pump housing, ensuring that the impeller can spin with minimal resistance. This is essential for maintaining the pump’s efficiency and longevity, as it allows for consistent water flow through the engine’s cooling system.

When integrated into a Water Pump Kit, the 4349732 plays a similarly vital role. The kit typically includes the water pump, gaskets, and other necessary components to replace a worn-out pump. The ball bearing within this kit ensures that the new pump operates smoothly from the outset, contributing to the overall reliability of the engine’s cooling system.

Conclusion

In summary, the 4349732 is a key component in ensuring the seamless operation of water pumps and water pump kits, directly influencing the engine’s cooling efficiency and durability. Its role in reducing friction and facilitating smooth rotation of mechanical components is crucial for maintaining the performance and reliability of commercial trucks.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.