This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4349746 Bearing Spacer is a component designed to facilitate the smooth operation of commercial trucks. Its role is integral to maintaining the efficiency and reliability of the truck’s engine or transmission system. Understanding its purpose and significance can help fleet operators and technicians ensure optimal performance and longevity of their vehicles.

Basic Concepts of Bearing Spacers

Bearing spacers are mechanical components used to maintain proper spacing between bearings in a system. They ensure that bearings are correctly aligned and that the load is evenly distributed, which contributes to the smooth operation of machinery 1. In the context of commercial trucks, bearing spacers play a role in reducing friction and wear, thereby enhancing the overall efficiency of the engine or transmission 2.

Purpose of the 4349746 Bearing Spacer

The 4349746 Bearing Spacer is specifically designed to function within the engine or transmission system of a truck. It helps in maintaining the correct distance between bearings, which is crucial for the proper functioning of rotating components. By ensuring that bearings are properly spaced, the spacer contributes to the stability and efficiency of the engine, reducing the likelihood of premature wear and failure.

Key Features

The 4349746 Bearing Spacer is constructed from high-quality materials that offer durability and resistance to wear. Its design specifications are tailored to meet the demanding conditions of commercial truck operations. Unique attributes such as precise machining and robust material composition enhance its performance, ensuring it can withstand the rigors of heavy-duty use.

Benefits of Using the 4349746 Bearing Spacer

Utilizing the 4349746 Bearing Spacer offers several advantages. It contributes to improved durability of the engine or transmission system by ensuring proper bearing alignment and load distribution. Enhanced performance is another benefit, as the spacer helps maintain the efficiency of rotating components. Additionally, the use of high-quality bearing spacers can lead to potential cost savings for fleet operators by reducing the frequency of maintenance and replacement needs 3.

Installation Process

Proper installation of the 4349746 Bearing Spacer is vital for its effective function. The process involves carefully placing the spacer between the bearings, ensuring it is correctly aligned and securely in position. Best practices include thorough cleaning of the installation area to prevent contamination and double-checking alignment to avoid common pitfalls such as misalignment or improper spacing.

Troubleshooting Common Issues

Common problems associated with bearing spacers can include misalignment, wear, or failure due to improper installation. Troubleshooting steps may involve inspecting the spacer for signs of damage or wear, ensuring it is correctly aligned, and verifying that it is made of the appropriate material for the application. Solutions may range from realigning the spacer to replacing it if it is found to be defective.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 4349746 Bearing Spacer. This includes periodic inspection for signs of wear or damage, ensuring it remains properly aligned, and cleaning the area around the spacer to prevent contamination. Adhering to these maintenance tips can help prevent issues and extend the lifespan of the component.

Compatibility and Application

The 4349746 Bearing Spacer is designed for specific applications within the commercial truck industry. It is compatible with certain types of engines and transmission systems, ensuring it meets the demands of heavy-duty operations. Understanding its compatibility and application is crucial for ensuring it functions effectively within the intended system.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a rich history of innovation and a strong reputation for reliability, Cummins continues to be a trusted name among fleet operators and technicians. The company’s commitment to excellence is reflected in its product offerings, including the 4349746 Bearing Spacer.

Cummins Engine Bearing Spacer 4349746 Compatibility

The Bearing Spacer part number 4349746, manufactured by Cummins, is designed to fit seamlessly within the engine architecture of the QSK95 series. Specifically, this part is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines.

In these engines, the Bearing Spacer 4349746 plays a crucial role in maintaining the precise alignment and spacing between the engine’s bearings. This ensures optimal performance and longevity of the engine components. The design of the Bearing Spacer is engineered to withstand the high stresses and operational demands of these heavy-duty engines, providing a reliable solution for maintaining engine integrity.

The integration of the Bearing Spacer 4349746 into the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines is a testament to Cummins’ commitment to quality and precision in engine manufacturing. This part is a critical component in the engine’s overall assembly, ensuring that the engine operates smoothly and efficiently.

Role of Part 4349746 Bearing Spacer in Engine Systems

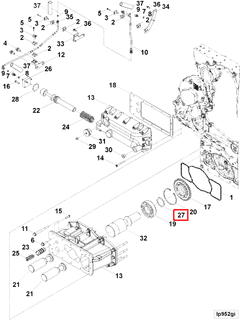

The part 4349746 Bearing Spacer is an essential component in maintaining the precise alignment and spacing between bearings within various engine systems. Its application is particularly significant in the context of the lubricating oil pump, lubricating oil pump kit, oil pump repair kit, and service kit.

In the lubricating oil pump, the Bearing Spacer ensures that the rotating components are correctly positioned. This proper alignment is vital for the efficient operation of the pump, allowing it to deliver oil consistently and reliably to the engine’s moving parts. Without the Bearing Spacer, the risk of misalignment increases, which can lead to inefficient oil flow and potential damage to the pump.

When considering the lubricating oil pump kit, the inclusion of the Bearing Spacer is fundamental. This kit often comprises multiple components designed to work in harmony. The Bearing Spacer plays a role in maintaining the structural integrity of the pump assembly, ensuring that all parts function as intended. It helps in preserving the pump’s efficiency and longevity by preventing undue wear and tear on the bearings.

In an oil pump repair kit, the Bearing Spacer is a key replacement part. During repairs, it is imperative to restore the exact spacing between bearings to guarantee the pump’s optimal performance post-repair. The Bearing Spacer facilitates this by providing the necessary distance and support, thereby contributing to the overall effectiveness of the repair process.

Lastly, within a service kit, the Bearing Spacer is often included to address potential issues related to bearing alignment during routine maintenance. Service kits are designed to enhance the engine’s performance and reliability. By incorporating the Bearing Spacer, these kits ensure that the oil pump and its associated components remain in top condition, facilitating smooth and efficient engine operation.

Conclusion

The Cummins 4349746 Bearing Spacer is a vital component in the maintenance and efficiency of commercial truck engines and transmission systems. Its precise design and high-quality materials ensure durability and reliable performance under heavy-duty conditions. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are key to maximizing the benefits of this Cummins part. Fleet operators and technicians can significantly enhance engine longevity and operational efficiency by incorporating the 4349746 Bearing Spacer into their maintenance and repair practices.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.