This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3002210 Bearing Spacer is a component designed to enhance the operation of commercial trucks. It is integral to maintaining the efficiency and reliability of the truck’s engine or drivetrain system. Understanding its purpose and significance can help in ensuring optimal performance and longevity of the vehicle.

Basic Concepts of Bearing Spacers

Bearing spacers are mechanical components used to maintain proper spacing between bearings in a system. They play a role in ensuring that bearings are correctly aligned and that the load is evenly distributed across the bearing surfaces. This contributes to the overall efficiency and reliability of the machinery by reducing wear and tear and preventing premature failure of the bearings 1.

Purpose of the 3002210 Bearing Spacer

The Cummins 3002210 Bearing Spacer is specifically designed to fit within the engine or drivetrain system of a truck. Its role is to provide the necessary spacing between bearings, which helps in maintaining alignment and ensuring that the load is evenly distributed. This contributes to the smooth operation of the engine and enhances the durability of the bearing components.

Key Features

The Cummins 3002210 Bearing Spacer is constructed from high-quality materials that are designed to withstand the rigors of commercial truck operation. Its dimensions are precisely engineered to fit within the specified engine or drivetrain system, ensuring optimal performance. Unique characteristics such as its durable construction and precise fit contribute to its effectiveness in enhancing the operation of the truck.

Benefits of Using the 3002210 Bearing Spacer

Utilizing the Cummins 3002210 Bearing Spacer offers several advantages. It helps in improving load distribution across the bearings, which can lead to enhanced durability and reduced wear. Additionally, it contributes to the overall efficiency of the system by ensuring that the bearings operate within their designed parameters, leading to smoother and more reliable operation 2.

Installation Considerations

Proper installation of the Cummins 3002210 Bearing Spacer is important to ensure its effectiveness. Guidelines and best practices should be followed to ensure that the spacer is correctly positioned and secured within the engine or drivetrain system. This may involve the use of specific tools or procedures to ensure a proper fit and alignment.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3002210 Bearing Spacer is important to ensure its continued effectiveness. This may involve periodic inspection for signs of wear or damage, and ensuring that it remains properly aligned and secured. Common issues that may arise include misalignment or wear, which can be addressed through proper maintenance and troubleshooting procedures.

Compatibility and Applications

The Cummins 3002210 Bearing Spacer is designed for use in specific types of trucks and engine models. It is important to ensure that it is compatible with the particular application to ensure optimal performance and longevity. Specific application notes may be available to guide the selection and installation of the spacer in the appropriate system.

Cummins Corporation Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of high-quality engine and component products. With a history of innovation and a commitment to quality, Cummins has built a reputation for providing reliable and efficient solutions for the commercial truck market. The Cummins 3002210 Bearing Spacer is one example of the company’s commitment to enhancing the performance and reliability of commercial trucks.

Cummins Bearing Spacer 3002210 Compatibility

The Cummins Bearing Spacer 3002210 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This bearing spacer is crucial for maintaining the integrity of the engine’s components by providing the necessary spacing between bearings, which helps in reducing friction and wear.

K19 and KTA19GC Engines

The K19 and KTA19GC engines are part of Cummins’ robust lineup, known for their reliability and efficiency. The Bearing Spacer 3002210 is engineered to fit these engines perfectly, ensuring that the bearings are correctly aligned and spaced. This alignment is critical for the smooth operation of the engine, preventing any undue stress on the bearings and other related components.

KTA19GC CM558 Engine

The KTA19GC CM558 engine, an advanced variant of the KTA19GC, also benefits from the precise fit of the Bearing Spacer 3002210. This engine model is designed for high-performance applications, and the bearing spacer plays a vital role in maintaining the engine’s precision and efficiency. The spacer ensures that the bearings are held in the correct position, which is essential for the engine’s longevity and performance.

QSK19 CM500 Engine

The QSK19 CM500 engine is another high-performance model in Cummins’ portfolio. The Bearing Spacer 3002210 is specifically designed to fit this engine, providing the necessary spacing and alignment for the bearings. This ensures that the engine operates smoothly and efficiently, reducing the risk of wear and tear on the bearings and other components.

Role of Part 3002210 Bearing Spacer in Engine Systems

The part 3002210 Bearing Spacer is integral to maintaining the precise alignment and spacing between various components within engine systems. Its application ensures optimal performance and longevity of the engine’s moving parts.

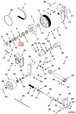

Drive System Integration

In the drive system, the Bearing Spacer is positioned between the drive components to maintain consistent spacing. This ensures that the drive components operate smoothly without undue stress or misalignment, which could lead to premature wear or failure.

Fan and Drive Arrangement

Within the fan and drive arrangement, the Bearing Spacer plays a significant role. It is placed between the fan assembly hub and the fan clutch to ensure that the fan operates at the correct distance from the engine. This spacing is vital for efficient airflow management and cooling performance.

Fan Assembly Hub and Fan Clutch

When installed between the fan assembly hub and the fan clutch, the Bearing Spacer helps in maintaining the correct axial alignment. This alignment is essential for the fan clutch to engage and disengage smoothly, ensuring that the fan operates only when necessary, thus conserving engine power.

Fan Drive Arrangement

In the fan drive arrangement, the Bearing Spacer ensures that the fan hub and the fan drive components are correctly spaced. This proper spacing is necessary for the efficient transfer of power from the engine to the fan, ensuring that the fan operates at the optimal speed for effective cooling.

Follower and Cam Mechanism

The Bearing Spacer is also utilized in the follower and cam mechanism. It ensures that the follower maintains the correct distance from the cam, allowing for smooth and precise operation of the cam-follower system. This is particularly important in valve train mechanisms where timing and precision are paramount.

Conclusion

Overall, the Bearing Spacer is a small yet significant component that contributes to the reliable and efficient operation of various engine systems by ensuring proper alignment and spacing between critical components. Its role in maintaining the integrity and performance of engines such as the K19, KTA19GC, KTA19GC CM558, and QSK19 CM500 cannot be overstated.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.