This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

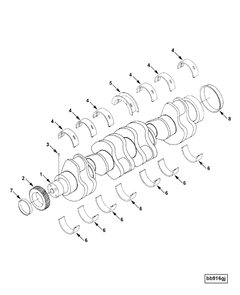

The 3921544 Crankshaft Thrust Bearing, manufactured by Cummins, is a vital component in heavy-duty truck engines. This bearing is designed to manage axial loads generated during engine operation, ensuring smooth and efficient performance. Cummins, a renowned name in the automotive industry, is known for producing high-quality components that enhance engine reliability and performance 1.

Basic Concepts of Crankshaft Thrust Bearings

A crankshaft thrust bearing is a type of bearing that manages axial loads within an engine. These loads are generated as the crankshaft rotates, creating forces that push against the crankshaft ends. The thrust bearing’s role is to absorb these forces, preventing damage to the crankshaft and other engine components. It operates by providing a smooth surface for the crankshaft to move against, reducing friction and wear 2.

Purpose of the 3921544 Crankshaft Thrust Bearing

This Cummins part plays a significant role in the operation of a truck engine by handling axial forces generated during engine operation. These forces, if not properly managed, can lead to excessive wear on the crankshaft and other components. The bearing ensures that these forces are evenly distributed, maintaining the integrity of the engine’s moving parts and contributing to overall engine efficiency 3.

Key Features

The 3921544 boasts several key features that enhance its performance and durability. It is composed of high-quality materials that provide excellent resistance to wear and corrosion. The design includes precision-machined surfaces to ensure smooth operation and minimal friction. Additionally, the bearing is engineered to withstand high loads and varying temperatures, making it suitable for the demanding conditions of heavy-duty truck engines.

Benefits

The advantages provided by this part include improved engine efficiency, reduced wear on other components, and enhanced overall engine performance. By effectively managing axial loads, the bearing helps to maintain the engine’s mechanical integrity, leading to longer service intervals and reduced maintenance costs. Furthermore, the bearing’s durable construction ensures reliable performance under a wide range of operating conditions.

Installation and Integration

Installing the 3921544 in a truck engine requires careful attention to detail. The process involves ensuring that the bearing is properly aligned with the crankshaft and that all mating surfaces are clean and free of debris. It is also important to follow manufacturer guidelines for torque specifications and clearances to ensure optimal performance. Best practices include using the appropriate tools and lubricants to facilitate a smooth installation.

Troubleshooting and Maintenance

Common issues associated with crankshaft thrust bearings include wear, misalignment, and contamination. Diagnostic methods for identifying problems may involve visual inspection, measurement of clearances, and analysis of engine performance data. Maintenance practices to ensure longevity and optimal performance include regular inspection of the bearing and its surrounding components, proper lubrication, and timely replacement when signs of wear are detected.

Performance Under Various Conditions

The 3921544 is designed to perform effectively under different operating conditions. Whether the engine is under high load, experiencing varying temperatures, or subjected to different types of driving, the bearing is engineered to maintain its performance. Its robust construction and precision design allow it to handle the stresses and strains of heavy-duty truck applications, ensuring reliable operation in a variety of environments.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability. The company offers a comprehensive range of products for heavy-duty trucks, including engines, drivetrain components, and aftermarket parts. Cummins’ commitment to excellence is evident in its rigorous testing protocols and continuous investment in research and development.

Role of Crankshaft Thrust Bearing in Engine Systems

The crankshaft thrust bearing, identified by part number 3921544, is an essential component in the operation of engine systems. Its primary function is to manage the axial loads that the crankshaft experiences during engine operation.

When the engine is running, the crankshaft undergoes rotational motion, which generates axial forces that attempt to push it along its axis. The crankshaft thrust bearing counteracts these forces, ensuring that the crankshaft remains stable and does not move excessively within the engine block. This stability is vital for maintaining proper alignment and reducing wear on other engine components.

In conjunction with the main bearings, the crankshaft thrust bearing supports the crankshaft, allowing it to rotate smoothly while withstanding the compressive forces. The main bearings are responsible for radial support, while the thrust bearing handles the axial loads. Together, they ensure that the crankshaft operates within precise tolerances, which is necessary for efficient engine performance and longevity.

Additionally, the crankshaft thrust bearing interacts with the engine’s lubrication system. Adequate oil flow is necessary to reduce friction and wear between the bearing surfaces. The oil film created by the lubrication system helps to dissipate heat and prevent metal-to-metal contact, further enhancing the durability and reliability of the engine.

Conclusion

In summary, the 3921544 Crankshaft Thrust Bearing plays a significant role in maintaining the structural integrity and operational efficiency of the engine by managing axial loads, supporting the crankshaft in collaboration with main bearings, and interacting effectively with the lubrication system.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.