This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

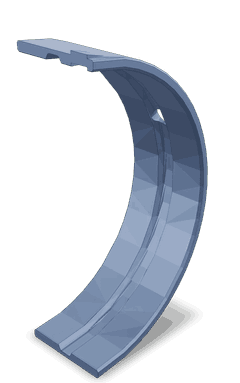

The Cummins 205143 Main Bearing is a component designed for use in commercial truck engines. It plays a role in the engine’s operation by supporting the crankshaft and enabling its smooth rotation. This bearing contributes to the efficient and reliable performance of the engine, enhancing the overall functionality and durability of the truck.

Basic Concepts of Main Bearings

Main bearings are components found in internal combustion engines. Their primary function is to support the crankshaft, allowing it to rotate with minimal friction. These bearings are positioned between the crankshaft and the engine block, playing a role in maintaining the crankshaft’s alignment and facilitating its movement. Proper operation of main bearings is vital for the engine’s performance, as they help to distribute the load exerted by the crankshaft and reduce wear on engine components 1.

Purpose of the Cummins 205143 Main Bearing

This Cummins part is specifically engineered to support the crankshaft in commercial truck engines. By providing a low-friction interface, it allows the crankshaft to rotate smoothly, which is essential for the engine’s operation. This bearing helps in maintaining the crankshaft’s precise alignment within the engine block, which is critical for the engine’s balance and efficiency. Additionally, it plays a role in absorbing and distributing the forces generated by the engine’s operation, thereby contributing to the engine’s longevity and reliability.

Key Features

The Cummins 205143 Main Bearing is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that offer excellent resistance to wear and corrosion. The design of the bearing includes precision-machined surfaces to ensure optimal fit and function within the engine. Additionally, it may incorporate advanced lubrication features to maintain a consistent oil film, which is vital for reducing friction and heat generation during operation 2.

Benefits

The use of this part in commercial truck engines offers several benefits. It contributes to improved engine efficiency by minimizing friction between the crankshaft and the engine block. This reduction in friction leads to lower energy losses, allowing the engine to operate more effectively. Furthermore, the bearing’s durable construction and advanced design features enhance its longevity, reducing the need for frequent replacements and maintenance. The consistent performance of the bearing also plays a role in maintaining overall engine reliability, which is crucial for the operation of commercial trucks.

Installation Considerations

When installing the Cummins 205143 Main Bearing, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes adhering to specified torque settings to secure the bearing in place without overtightening, which could lead to damage. Alignment checks are also crucial to ensure the crankshaft is properly positioned within the engine block. Preparatory steps, such as cleaning the bearing surfaces and inspecting for any damage, are necessary to prevent issues during operation.

Troubleshooting and Maintenance

Common issues associated with main bearings include excessive wear, misalignment, and lubrication problems. Diagnostic techniques for identifying these issues may involve visual inspections, measurement of clearances, and analysis of oil samples for metal particles. Regular maintenance practices, such as monitoring oil quality and pressure, and adhering to recommended service intervals, are important for ensuring the longevity and performance of the Cummins 205143 Main Bearing. Early detection of problems and timely intervention can prevent more serious engine damage 3.

Performance in Various Operating Conditions

The Cummins 205143 Main Bearing is designed to perform under a range of operating conditions, including high loads, extreme temperatures, and varying speeds. Its material composition and design features allow it to withstand the stresses and thermal cycles encountered in commercial truck engines. For optimal performance, it is important to ensure proper lubrication and maintenance, as these factors can significantly influence the bearing’s ability to operate effectively under demanding conditions.

Comparison with Other Main Bearings

When compared to other main bearings available in the market, the Cummins 205143 Main Bearing stands out for its specific design and performance characteristics. Differences may include material composition, lubrication features, and compatibility with specific engine types. The suitability of a main bearing for a particular application depends on factors such as the engine’s design, operating conditions, and maintenance requirements. It is important to select a bearing that meets the specific needs of the engine to ensure optimal performance and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the diverse needs of its customers, from heavy-duty trucks to off-highway equipment. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Conclusion

The Cummins 205143 Main Bearing is a critical component in the operation of commercial truck engines. Its design and features contribute to the efficient and reliable performance of the engine, enhancing the overall functionality and durability of the truck. Proper installation, maintenance, and understanding of its role in the engine system are essential for maximizing the benefits of this part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Cengage Learning, 2011.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.