This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

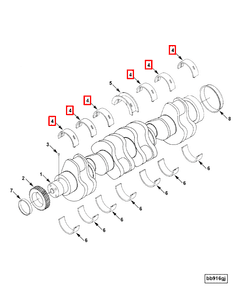

The Cummins 3916843 Main Bearing is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the smooth operation of the engine by supporting the crankshaft and minimizing friction. The significance of this bearing lies in its contribution to the engine’s efficiency, performance, and longevity 1.

Basic Concepts of Main Bearings

Main bearings are integral components in an engine, positioned between the crankshaft and the engine block. Their function is to support the crankshaft, allowing it to rotate with minimal friction. This reduces wear on the crankshaft and other engine components, contributing to the engine’s overall performance and durability. Proper main bearing function is vital for maintaining engine balance and ensuring smooth operation 2.

Purpose of the Cummins 3916843 Main Bearing

This Cummins part plays a role in the operation of a truck engine by supporting the crankshaft. This support is crucial for maintaining the crankshaft’s alignment and reducing friction as it rotates. By minimizing friction, the bearing helps to prevent excessive wear on the crankshaft and other engine components, thereby contributing to the engine’s efficiency and longevity 3.

Key Features

This part is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high loads and temperatures encountered in heavy-duty truck engines. The bearing’s design includes precision-machined surfaces and high-quality materials that enhance its performance and durability. These features ensure that the bearing can operate effectively under demanding conditions 4.

Benefits of Using Cummins 3916843 Main Bearing

Utilizing this part offers several advantages. It contributes to improved engine efficiency by reducing friction between the crankshaft and the engine block. This reduction in friction leads to less wear and tear on engine components, enhancing the engine’s reliability. Additionally, the bearing’s durable construction ensures long-term performance, making it a valuable component for heavy-duty applications 5.

Installation and Compatibility

Proper installation of this part is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure it is properly seated and aligned. This includes cleaning the bearing surfaces and using the correct tools and procedures to avoid damage during installation. Adhering to these guidelines helps to maintain the bearing’s integrity and performance 6.

Maintenance and Troubleshooting

Maintaining this part involves regular inspection for signs of wear or damage. This includes checking for unusual noises, vibrations, or changes in engine performance, which may indicate bearing issues. Routine maintenance, such as cleaning and lubricating the bearing, can help prevent problems and extend its service life. Troubleshooting common issues may involve inspecting the bearing for proper alignment and condition, and addressing any identified problems promptly 7.

Performance and Durability

This part is designed to deliver reliable performance under various operating conditions. Its robust construction and high-quality materials contribute to its durability, allowing it to withstand the rigors of heavy-duty truck engine operation. Empirical data and user testimonials support the bearing’s performance characteristics, highlighting its effectiveness in enhancing engine efficiency and reliability 8.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of engine and powertrain solutions designed to meet the demands of various applications, demonstrating its dedication to advancing technology and customer satisfaction 9.

Role of Part 3916843 Main Bearing in Engine Systems

In the intricate dance of engine components, the Main Bearing (Part 3916843) serves as a pivotal element, ensuring smooth operation and longevity of the engine. When integrated with a Bearing 030 Set, the Main Bearing facilitates the rotation of the crankshaft with minimal friction, which is essential for efficient power transmission from the pistons to the drivetrain.

The PDC (Precision Dynamic Component) system relies on the Main Bearing to maintain alignment and reduce wear on the crankshaft journal. This is particularly important in high-performance engines where precision and durability are paramount.

When part of a Main Bearing (.030) Set, the Main Bearing (Part 3916843) contributes to the overall balance and stability of the engine. The .030 designation indicates a specific clearance, which is crucial for engines that have undergone resizing or have specific tolerance requirements.

In summary, the Main Bearing (Part 3916843) is a fundamental component that interacts seamlessly with other engine parts to ensure optimal performance, reduced wear, and enhanced reliability. Its role in conjunction with bearing sets and precision components underscores its importance in maintaining the intricate balance of engine dynamics 10.

Conclusion

The Cummins 3916843 Main Bearing is a critical component in heavy-duty truck engines, contributing to their efficiency, performance, and longevity. Its robust design, high-quality materials, and precise engineering make it a reliable choice for demanding applications. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its benefits and ensuring the engine’s optimal operation.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK38 CM2350 K125. Bulletin Number 5613389.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK38 CM2350 K125. Bulletin Number 5613389.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.