This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3001601 V-Belt is a component designed to facilitate the operation of various systems within commercial trucks. Its purpose is to transfer power from the engine to auxiliary components, ensuring the efficient functioning of critical systems. The significance of this V-Belt lies in its ability to maintain the operational integrity of the truck by driving essential components and supporting various systems.

Basic Concepts of V-Belts

V-Belts are mechanical power transmission devices characterized by their trapezoidal cross-section. This design allows them to fit snugly into corresponding pulleys, enhancing grip and reducing slippage. V-Belts are constructed from materials such as rubber, polyester, or other synthetic compounds, providing durability and flexibility. They differ from flat belts and timing belts in their cross-sectional shape and the manner in which they engage with pulleys, offering advantages in power transmission efficiency and longevity 1.

Role of the 3001601 V-Belt in Truck Operation

This Cummins part plays a role in the operation of a commercial truck by driving components such as the alternator, water pump, and air conditioning compressor. It supports systems like the electrical system, engine cooling, and climate control, ensuring these systems function correctly. The V-Belt’s ability to transmit power efficiently contributes to the overall performance and reliability of the truck 2.

Key Features of the 3001601 V-Belt

The Cummins 3001601 V-Belt is distinguished by its material composition, which typically includes a robust rubber compound reinforced with polyester cords. This design enhances its durability and resistance to wear. The V-Belt’s trapezoidal cross-section ensures a secure fit on pulleys, reducing the likelihood of slippage. Additionally, it is engineered to withstand the high temperatures and dynamic loads encountered in commercial truck applications, contributing to its performance and longevity 3.

Benefits of Using the 3001601 V-Belt

Utilizing the Cummins 3001601 V-Belt offers several benefits, including improved efficiency in power transmission, enhanced reliability under demanding conditions, and increased longevity compared to other V-Belts. Its design and material composition contribute to reduced maintenance requirements and lower operational costs, making it a valuable component for commercial truck operators.

Installation Guidelines

Proper installation of the Cummins 3001601 V-Belt involves several steps to ensure optimal performance. Begin by ensuring the engine is cool and the truck is securely supported. Use the appropriate tools to remove the old V-Belt and inspect the pulleys for any damage or wear. Install the new V-Belt by routing it according to the manufacturer’s specifications, ensuring it is properly aligned and tensioned. Verify the tension by applying moderate pressure to the belt; it should deflect slightly but return to its original position. Finally, start the engine and check for proper operation and belt alignment.

Maintenance Tips

Regular maintenance of the Cummins 3001601 V-Belt is crucial for ensuring continued efficient operation. Inspect the belt regularly for signs of wear, cracking, or glazing. Check the tension periodically and adjust as necessary to maintain the recommended specifications. Replace the V-Belt at the manufacturer’s recommended intervals or when signs of significant wear are observed. Keeping the belt clean and free from contaminants will also contribute to its longevity and performance.

Troubleshooting Common Issues

Common issues associated with V-Belts include slippage, wear, and noise. Slippage can often be addressed by adjusting the tension of the belt. Wear may indicate the need for replacement, especially if the belt shows signs of cracking or glazing. Noise can be caused by misalignment or contamination; ensuring proper alignment and cleaning the belt and pulleys can often resolve this issue. Regular inspection and maintenance can help prevent these problems and ensure the V-Belt operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and aftermarket parts. Cummins’ dedication to advancing technology and improving efficiency has established it as a trusted name in the automotive and heavy-duty truck industries.

V-Belt 3001601 Compatibility with Cummins Engines

This Cummins part is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and longevity. This belt is engineered to handle the specific demands of these engines, providing reliable power transmission and reducing the risk of mechanical failures.

V28 Engine Group

The V-Belt 3001601 is compatible with the V28 engine series, which includes:

- V28-3000: This engine is known for its robust design and high power output. The V-Belt 3001601 is specifically tailored to fit the pulleys and components of the V28-3000, ensuring efficient power transfer and minimal wear.

- V28-3500: Another high-performance engine in the V28 series, the V28-3500 benefits from the precise engineering of the V-Belt 3001601. This belt is designed to withstand the rigorous demands of this engine, providing consistent performance and durability.

- V28-4000: The V28-4000 engine is equipped with the V-Belt 3001601 to ensure smooth operation and reliable power transmission. This belt is engineered to fit the specific dimensions and requirements of the V28-4000, enhancing the engine’s overall efficiency.

The V-Belt 3001601 is a critical component for maintaining the performance and reliability of these engines, ensuring that they operate at peak efficiency.

Role of Part 3001601 V-Belt in Engine Systems

The V-Belt, identified as part 3001601, is integral to the operation of several key components within engine systems. Its primary function is to transmit power from the engine to auxiliary components, ensuring they operate efficiently and effectively.

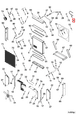

Fan Drive

In the context of the fan drive, the V-Belt plays a significant role in transferring rotational energy from the engine’s crankshaft to the cooling fan. This transfer is essential for maintaining optimal engine temperature. As the engine operates, it generates heat, which, if not managed properly, can lead to overheating and potential damage. The V-Belt ensures that the cooling fan spins at the necessary speed to draw air through the radiator, dissipating heat away from the engine. This continuous cycle is vital for the engine’s longevity and performance.

Radiator

The radiator is another component where the V-Belt’s role is indirectly but significantly felt. While the radiator itself does not connect directly to the V-Belt, its efficiency is dependent on the proper functioning of the cooling fan, which is driven by the V-Belt. The radiator’s job is to cool the engine coolant as it circulates through the engine. Efficient cooling is paramount to prevent engine overheating, which can cause severe damage. The V-Belt ensures that the cooling fan operates at the correct speed, enhancing the radiator’s ability to maintain the engine at a safe operating temperature.

Conclusion

In summary, the V-Belt (part 3001601) is a key component in the engine’s auxiliary systems, facilitating the efficient operation of the fan drive and, by extension, supporting the radiator’s cooling function. Its reliable performance is essential for the overall health and efficiency of the engine system.

-

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.