This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

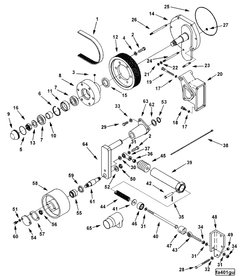

The Cummins 3090060 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying the necessary force to prevent belt slippage, which can lead to inefficient operation and potential damage to the belt and driven components. Maintaining proper belt tension is important for the reliable operation of the engine and its accessory systems 1.

Purpose of the Cummins 3090060 Belt Tensioner

The Cummins 3090060 Belt Tensioner is designed to maintain optimal belt tension for various engine components in a truck. It ensures that belts remain properly aligned and tensioned, which is vital for the efficient transfer of power to components such as the alternator, water pump, and air conditioning compressor.

Key Features

The Cummins 3090060 Belt Tensioner is constructed with durable materials to withstand the rigors of commercial truck operation. Its design includes a mechanism that automatically adjusts to maintain consistent belt tension, even as belts stretch or wear over time. Unique attributes of this tensioner may include a robust housing, precision-machined components, and a self-adjusting feature that enhances performance and longevity.

Benefits of Using the Cummins 3090060 Belt Tensioner

Utilizing the Cummins 3090060 Belt Tensioner can lead to improved engine efficiency, as it ensures that belts operate within their optimal tension range. This reduces wear on belts and enhances the reliability of the truck’s accessory systems. Consistent belt tension also contributes to the smooth operation of engine components, potentially leading to better overall performance and fuel efficiency 2.

Installation and Compatibility

Proper installation of the Cummins 3090060 Belt Tensioner is important for its effective operation. Specific guidelines should be followed to ensure that the tensioner is correctly positioned and secured. Considerations for different truck models may include alignment with existing belt paths and compatibility with other engine components.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3090060 Belt Tensioner involves checking for signs of wear or damage, ensuring that it operates smoothly, and verifying that belt tension remains within the manufacturer’s specifications. Troubleshooting may involve identifying unusual noises, belt slippage, or signs of excessive wear, which could indicate the need for adjustment or replacement 3.

Common Issues and Solutions

Common problems associated with belt tensioners can include noise from the tensioner pulley, belt slippage, or failure of the tensioner mechanism. Solutions may range from simple adjustments to replace worn components or the entire tensioner assembly, depending on the severity of the issue.

Performance Enhancements

The Cummins 3090060 Belt Tensioner contributes to overall engine performance by ensuring that belts operate efficiently. This can lead to improved fuel efficiency and durability of the truck’s accessory drive system, as components are powered consistently and without excessive strain.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Belt Tensioner 3090060 Compatibility with Cummins Engines

The Belt Tensioner 3090060, manufactured by Cummins, is a critical component designed to maintain proper tension in the engine’s belt system. This part is compatible with several Cummins engine models, ensuring optimal performance and longevity of the belt system. Below is a detailed overview of the engines with which this belt tensioner is compatible.

Compatible Engines

- QSK19 CM2350 K144G

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QST30 CM552

- K19

The Belt Tensioner 3090060 is engineered to fit seamlessly within the engine configurations of the listed models. This compatibility ensures that the tensioner can effectively manage the belt’s tension, reducing wear and tear and preventing potential belt-related failures.

Grouping of Compatible Engines

The engines listed can be grouped based on their model series and specifications:

-

QSK19 Series

- QSK19 CM2350 K144G

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

-

QST30 Series

- QST30 CM552

-

K19

The QSK19 series engines, including the QSK19 CM2350 K144G, QSK19 CM2350 K114, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, are designed for high-performance applications and benefit from the precise tension management provided by the Belt Tensioner 3090060. Similarly, the QST30 CM552 and the K19 engine also rely on this component to maintain the integrity of their belt systems.

By ensuring that the Belt Tensioner 3090060 is used with these engines, operators can maintain the efficiency and reliability of their engine systems, avoiding potential downtime and costly repairs.

Role of Part 3090060 Belt Tensioner in Engine Systems

The part 3090060 Belt Tensioner is an integral component in maintaining the optimal operation of various engine systems. It ensures that the drive belts within the engine compartment are kept at the correct tension, which is essential for the efficient transfer of power to auxiliary components.

Interaction with Fan Drive

The Belt Tensioner works in conjunction with the Fan Drive to maintain consistent belt tension. As the engine operates, the Fan Drive adjusts the fan speed based on the engine’s cooling needs. The Belt Tensioner compensates for any changes in belt length or wear, ensuring that the belt remains taut and effectively drives the fan.

Coordination with Fan Drive Idle Assembly

In systems equipped with a Fan Drive Idle Assembly, the Belt Tensioner plays a key role during idle conditions. When the engine is idling, the Fan Drive Idle Assembly reduces fan speed to minimize drag and improve fuel efficiency. The Belt Tensioner ensures that the belt does not slacken during these periods, maintaining reliable operation of the fan and other driven components.

Integration with Fan Drive Idler Assembly

The Fan Drive Idler Assembly often includes pulleys that guide the belt around the fan drive system. The Belt Tensioner collaborates with this assembly to keep the belt properly aligned and tensioned. This is particularly important in systems where the belt path is complex, ensuring smooth and efficient power transmission to the fan and other accessories.

Conclusion

In summary, the part 3090060 Belt Tensioner is essential for the harmonious operation of the fan drive, fan drive idle assembly, and fan drive idler assembly. Its role in maintaining belt tension ensures that these components function efficiently, contributing to the overall performance and reliability of the engine system.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.