This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

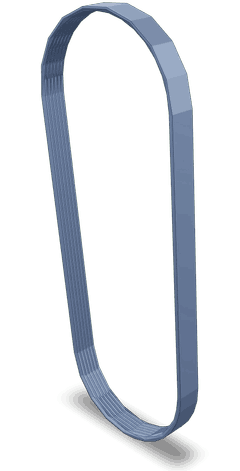

The Cummins 3693220 Self Tensioning Belt is a critical component designed to maintain optimal tension in the belt drive system of commercial trucks. This part ensures efficient operation of the engine’s auxiliary systems, including the alternator, water pump, and air conditioning compressor. Its significance lies in its automatic tension adjustment capability, which reduces the need for manual adjustments and enhances the reliability of the truck’s engine system 1.

Basic Concepts of Self Tensioning Belts

Self tensioning belts are engineered to automatically maintain the correct tension in the belt drive system. This is achieved through a tensioner mechanism that adjusts the belt’s tension as it wears or stretches over time. In automotive applications, self tensioning belts are essential for ensuring the smooth and efficient operation of various engine components. They help in reducing maintenance requirements and improving the overall performance and longevity of the engine system 2.

Role of the 3693220 Self Tensioning Belt in Truck Operation

The Cummins 3693220 Self Tensioning Belt is integral to the operation of a truck’s engine system. It works in conjunction with the tensioner to keep the belt at the optimal tension, ensuring that components like the alternator, water pump, and air conditioning compressor operate efficiently. This belt’s role is to transmit power from the engine to these auxiliary components, facilitating their function without the need for frequent manual adjustments 3.

Key Features

The Cummins 3693220 Self Tensioning Belt is characterized by its robust design and high-quality materials. It is constructed from durable compounds that resist wear and environmental factors, ensuring long-lasting performance. The belt features a unique ribbed profile that enhances grip and power transmission efficiency. Additionally, its self-tensioning mechanism allows for automatic adjustments, reducing the likelihood of belt slippage and associated performance issues.

Benefits of Using the 3693220 Self Tensioning Belt

Utilizing the Cummins 3693220 Self Tensioning Belt offers several advantages. It contributes to improved engine performance by ensuring consistent tension and power transmission to auxiliary components. The belt’s design and materials promote durability, reducing the frequency of replacements. Moreover, its self-tensioning feature simplifies maintenance, as it eliminates the need for manual tension adjustments, thereby saving time and labor costs.

Installation Process

Installing the Cummins 3693220 Self Tensioning Belt requires careful attention to ensure proper function. The process involves routing the belt around the pulleys of the engine’s auxiliary components, engaging the tensioner to achieve the correct tension, and verifying that the belt is properly aligned and tensioned. Tools such as a socket wrench may be necessary to adjust the tensioner. It is important to consult the vehicle’s service manual for specific instructions related to the truck model.

Common Issues and Troubleshooting

Common issues with self tensioning belts include wear, cracking, and misalignment. These problems can lead to reduced efficiency or complete failure of the belt drive system. Troubleshooting involves inspecting the belt for signs of wear or damage, checking the tensioner for proper operation, and ensuring that all pulleys are aligned correctly. Addressing these issues promptly can prevent more serious engine problems and ensure the continued reliable operation of the truck.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3693220 Self Tensioning Belt, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring the tensioner operates correctly, and keeping the belt clean and free of debris. Following the manufacturer’s guidelines for inspection intervals and replacement can help maintain the efficiency of the engine’s auxiliary systems.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. Their products, including the 3693220 Self Tensioning Belt, are designed with precision and durability in mind, reflecting Cummins’ dedication to enhancing the performance and reliability of commercial vehicles.

Integration of Part 3693220 Self Tensioning Belt with Engine Systems

The Part 3693220 Self Tensioning Belt is engineered to optimize the performance and efficiency of various engine components through its seamless integration. This belt is specifically designed to work in harmony with the mounting system and the refrigerant compressor, ensuring smooth operation and reduced maintenance requirements.

Interaction with Mounting System

The mounting system plays a pivotal role in securing the self-tensioning belt in place. It provides the necessary framework that allows the belt to maintain optimal tension across its operational range. The mounting points are strategically positioned to accommodate the dynamic movement of the belt, ensuring that it remains properly aligned with the pulleys it engages. This alignment is essential for the efficient transfer of power from the engine to the driven components, minimizing slippage and wear.

Coordination with Refrigerant Compressor

The refrigerant compressor is a key component in the engine’s air conditioning system, responsible for pressurizing the refrigerant to facilitate cooling. The self-tensioning belt ensures that the compressor operates at peak efficiency by maintaining consistent tension, which is vital for the compressor’s reliable performance. As the engine speed varies, the self-tensioning mechanism automatically adjusts the belt’s tension, accommodating the changing demands placed on the compressor. This dynamic adjustment helps to prevent overloading and ensures that the compressor can maintain the desired cooling effect under all operating conditions.

Conclusion

In summary, the Cummins 3693220 Self Tensioning Belt is an integral component that enhances the functionality of the mounting system and the refrigerant compressor. Its ability to self-adjust tension in real-time contributes to the overall reliability and efficiency of the engine system, making it a valuable asset in modern engine designs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.