This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

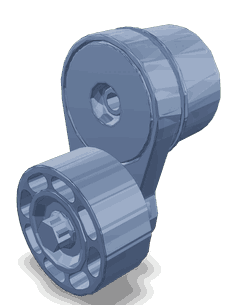

The Belt Tensioner 3693698 is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its high-quality diesel engines and components. This belt tensioner is designed for use in commercial trucks, where it plays a significant role in ensuring the efficient operation of the engine’s accessory belt system 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in a truck’s engine system to maintain the correct tension on the accessory drive belts. These belts drive various components such as the alternator, water pump, and power steering pump. The tensioner operates by applying consistent pressure to the belt, which helps in reducing slippage and wear, ensuring that these components receive the necessary power to function correctly 2.

Purpose of the 3693698 Belt Tensioner

The 3693698 Belt Tensioner is integral to the operation of a truck’s engine system. It maintains optimal belt tension for accessories like the alternator, water pump, and power steering pump. By keeping the belts properly tensioned, it ensures that these accessories operate efficiently, which is vital for the overall performance and reliability of the truck 3.

Key Features

The 3693698 Belt Tensioner is characterized by its robust design and the use of high-quality materials. It features a durable construction that can withstand the demanding conditions of commercial truck operations. The tensioner is engineered to provide consistent belt tension under varying loads and temperatures, enhancing its performance and longevity. Additionally, its design allows for easy installation and maintenance, making it a practical choice for fleet managers and mechanics 4.

Benefits of Using the 3693698 Belt Tensioner

Utilizing the 3693698 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that the accessory belts operate under the correct tension. This reduces wear on both the belts and the accessories they drive, leading to longer service intervals and lower maintenance costs. Furthermore, the tensioner enhances the overall performance of the truck by ensuring that critical components receive consistent power, which is essential for reliable operation 5.

Installation and Compatibility

Proper installation of the 3693698 Belt Tensioner is crucial for its effective operation. It is designed to meet specific requirements for compatibility with various truck models. When installing, it is important to follow the manufacturer’s guidelines to ensure that the tensioner is correctly positioned and secured. This includes checking for any specific mounting requirements or adjustments needed for different truck configurations 6.

Troubleshooting and Maintenance

Common issues with the 3693698 Belt Tensioner may include belt slippage, unusual noises, or signs of wear. Troubleshooting these problems involves checking the tensioner for proper operation, ensuring that it moves freely and applies the correct amount of tension to the belt. Regular maintenance, such as inspecting the tensioner for signs of wear or damage and ensuring that it operates smoothly, can help prevent issues and extend the component’s lifespan 7.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components for commercial vehicles. The company’s history of innovation and excellence in engine technology underscores its position as a trusted provider of automotive parts, including the 3693698 Belt Tensioner 8.

Belt Tensioner 3693698 Compatibility with Cummins Engines

The Belt Tensioner part number 3693698, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral in maintaining the proper tension of the engine’s serpentine belt, ensuring optimal performance and longevity of the engine components 9.

X12 CM2350 and X119B Engines

The Belt Tensioner 3693698 is specifically engineered to fit the X12 CM2350 and X119B engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The tensioner ensures that the belt remains taut, preventing slippage and reducing wear on the belt and pulleys 10.

Grouping of Engines

When considering the compatibility of the Belt Tensioner 3693698, it is essential to recognize that the X12 CM2350 and X119B engines share similar design principles and mounting configurations. This commonality allows the tensioner to be a direct fit for both engines, simplifying maintenance and replacement processes 11.

Importance of Proper Fitment

Ensuring that the Belt Tensioner 3693698 is correctly installed is crucial for the overall health of the engine. An improperly fitted tensioner can lead to belt failure, which can cause significant engine damage and downtime. The precision engineering of this part guarantees that it will perform reliably under the demanding conditions these engines operate in 12.

Maintenance and Reliability

Regular maintenance of the Belt Tensioner 3693698 is recommended to ensure continued performance. Checking for wear and proper tension is a simple yet effective way to prevent unexpected failures. Cummins’ reputation for quality and durability is reflected in this part, providing users with peace of mind regarding its performance and longevity 13.

Role of Part 3693698 Belt Tensioner in Engine Systems

In the orchestration of an engine’s auxiliary systems, the part 3693698 Belt Tensioner assumes a significant role by ensuring the proper functioning of the drive belt. This, in turn, impacts the performance of components such as the alternator and other driven accessories 14.

Interaction with the Drive Belt

The Belt Tensioner is engineered to maintain the correct tension on the drive belt. This is essential for the efficient transfer of power from the engine to the driven components. Without adequate tension, the belt may slip, leading to inefficient power transmission and potential damage to the belt and the components it drives 15.

Contribution to Alternator Performance

A well-tensioned drive belt is fundamental to the alternator’s ability to generate electricity. The alternator relies on the consistent rotation imparted by the drive belt to convert mechanical energy into electrical energy. The Belt Tensioner ensures that the belt remains taut, allowing for a steady and reliable rotation of the alternator pulley. This consistent tension is key to maintaining the alternator’s output, which is vital for the vehicle’s electrical systems 16.

Ensuring Accessory Drive Efficiency

Beyond the alternator, the drive belt often serves multiple accessories, such as the water pump, air conditioning compressor, and power steering pump. The Belt Tensioner’s role in maintaining belt tension is therefore integral to the operation of these components as well. It ensures that each accessory receives the necessary power to function correctly, contributing to the overall efficiency and reliability of the engine system 17.

Conclusion

The 3693698 Belt Tensioner by Cummins is a critical component in the maintenance and efficiency of commercial truck engines. Its robust design, ease of installation, and compatibility with various Cummins engines make it a reliable choice for fleet managers and mechanics. Regular maintenance and proper installation are key to ensuring the longevity and performance of this part, ultimately contributing to the overall reliability and efficiency of the truck’s engine system.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613154, 2014.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613154, 2014.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613154, 2014.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613154, 2014.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.