3694214

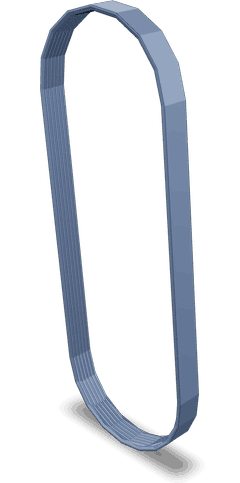

Self Tensioning Belt

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Self Tensioning Belts

Self tensioning belts, also known as automatic tensioners, are essential components in modern engine systems. These belts automatically maintain optimal tension, ensuring efficient power transmission from the engine to various accessories such as the alternator, water pump, and air conditioning compressor 1. Unlike traditional belts that require manual adjustments, self tensioning belts use a spring-loaded mechanism to keep the belt tight, reducing the need for frequent maintenance 2.

How a Self Tensioning Belt Works

A self tensioning belt system typically includes a tensioner pulley with a spring or hydraulic mechanism. The tensioner pulley adjusts the belt’s tension by applying a consistent force against the belt. This ensures that the belt remains tight and does not slip, which is crucial for the proper functioning of engine accessories. The tensioner pulley can move along a guide rail, allowing it to adjust the belt tension as needed.

Purpose of the Cummins 3694214 Self Tensioning Belt

The Cummins 3694214 Self Tensioning Belt is specifically designed for use in heavy-duty trucks and commercial vehicles. Its primary role is to drive the engine’s accessories while maintaining the correct tension. This belt is engineered to withstand high temperatures, pressures, and loads, making it ideal for the demanding conditions of commercial truck operations. By ensuring that the belt remains properly tensioned, it helps to prevent slippage, reduce wear, and improve the overall efficiency of the engine.

Importance in Truck Operations

In commercial trucks, the reliability of engine accessories is paramount. The alternator charges the battery, the water pump maintains the engine’s temperature, and the air conditioning compressor provides comfort for the driver. A malfunctioning self tensioning belt can lead to a cascade of failures, potentially causing the vehicle to break down and incur costly repairs. By using a high-quality self tensioning belt like the Cummins 3694214, fleet operators can ensure that their trucks remain reliable and perform optimally.

Troubleshooting and Maintenance

Proper maintenance of the self tensioning belt is essential to prevent failures and extend its lifespan. Here are some troubleshooting tips and maintenance practices:

-

Visual Inspection: Regularly inspect the belt for signs of wear, such as cracks, fraying, or glazing. If any of these signs are present, the belt should be replaced 2.

-

Tension Check: Although self tensioning belts are designed to maintain tension automatically, it is still important to periodically check the belt tension. A loose belt can indicate a problem with the tensioner mechanism 1.

-

Tensioner Functionality: Ensure that the tensioner pulley is moving freely along the guide rail and that the spring or hydraulic mechanism is functioning correctly. If the tensioner is stuck or damaged, it can cause the belt to become loose or over-tensioned 2.

-

Replacement: Follow the manufacturer’s recommended replacement intervals for the self tensioning belt. Typically, belts should be inspected every 6 months to 1 year, depending on the vehicle’s usage and operating conditions 2.

Cummins: A Leader in Engine Technology

Cummins is a globally recognized leader in the design and manufacture of engines, engine components, and related technologies. With a history spanning over a century, Cummins has built a reputation for producing high-quality, reliable, and efficient products. The company’s commitment to innovation and excellence has made it a trusted name in the automotive and heavy-duty truck industries. Cummins’ self tensioning belts are engineered to meet the rigorous demands of commercial truck operations, providing reliable performance and long-lasting durability.

Role of Part 3694214 Self Tensioning Belt in Engine Systems

The 3694214 Self Tensioning Belt is integral to the efficient operation of various engine components, ensuring seamless functionality and performance.

Interaction with the Mounting System

When installed, the Self Tensioning Belt engages with the mounting brackets specifically designed to hold it in place. This interaction is vital for maintaining the correct tension across the belt, which is essential for the transfer of power to other components. The mounting system, therefore, plays a supportive role, ensuring that the belt remains securely in position and operates within the optimal tension range.

Coordination with the Refrigerant Compressor

The refrigerant compressor is another component that relies on the efficient operation of the Self Tensioning Belt. The belt drives the compressor, allowing it to circulate refrigerant through the air conditioning system. This circulation is necessary for the cooling process, ensuring that the engine compartment and passenger cabin maintain appropriate temperatures. The consistent and reliable drive provided by the belt is fundamental to the compressor’s ability to perform its function effectively.

Conclusion

Understanding the role and maintenance of the Cummins 3694214 Self Tensioning Belt is crucial for engineers, mechanics, truck drivers, and fleet operators. By ensuring that this critical component is properly maintained, operators can enhance the reliability and efficiency of their commercial trucks, ultimately leading to cost savings and improved performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.