This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

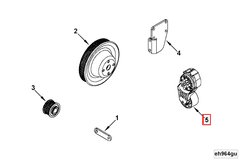

The Cummins 3967189 Belt Tensioner is a critical component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying the necessary force to prevent belt slippage, which can lead to inefficient operation and potential damage to the engine components 1. Maintaining proper belt tension is important for the longevity and performance of the belts and the components they drive, such as the alternator, water pump, and air conditioning compressor.

Purpose of the Cummins 3967189 Belt Tensioner

The Cummins 3967189 Belt Tensioner ensures that the belts remain under the correct amount of tension. This is vital for the optimal performance of engine components that are driven by these belts. By maintaining the right tension, the tensioner helps in the smooth and efficient transfer of power from the engine to these components.

Key Features

The Cummins 3967189 Belt Tensioner is characterized by several design elements and materials that enhance its performance and durability. It is constructed with high-quality materials to withstand the rigors of commercial truck operation. Unique characteristics may include a robust housing, precision-machined components, and a design that allows for easy adjustment and maintenance.

Benefits

Using the Cummins 3967189 Belt Tensioner can lead to improved engine efficiency, as it ensures that belts operate within their optimal tension range. This can result in reduced wear on both the belts and the pulleys they engage with. Additionally, the overall performance of the truck may be enhanced, as the engine components driven by the belts will operate more efficiently 2.

Installation Process

Installing the Cummins 3967189 Belt Tensioner involves a series of steps that require specific tools and equipment. It is important to follow the manufacturer’s guidelines for installation to ensure proper function. Considerations for installation include aligning the tensioner correctly with the belt and pulley system, securing it in place, and verifying that the belt tension is within the specified range.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3967189 Belt Tensioner, regular maintenance is recommended. This includes inspecting the tensioner for signs of wear or damage, ensuring that it is properly lubricated if required, and following the manufacturer’s guidelines for replacement intervals. Proper maintenance can help prevent issues such as belt slippage or tensioner failure.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3967189 Belt Tensioner include noise, slippage, or misalignment. These issues can often be identified through regular inspection and maintenance. Recommended solutions may involve adjusting the tensioner, replacing worn components, or addressing any underlying issues that may be causing the problem 3.

Compatibility and Applications

The Cummins 3967189 Belt Tensioner is designed for use with specific truck models and engine types. Its applications span various commercial truck settings, where it is used to maintain the integrity of the belt-driven systems within the engine.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a history of producing high-quality automotive components. The company is known for its commitment to innovation and excellence in the industry, providing reliable and durable parts for a wide range of applications.

Role of Part 3967189 Belt Tensioner in Engine Systems

In the orchestration of an engine’s auxiliary systems, the 3967189 Belt Tensioner assumes a significant role by ensuring the proper functioning of the alternator drive system. This component is integral to maintaining the correct tension on the drive belt, which is essential for the efficient operation of the alternator.

The alternator drive system relies on a consistent and optimal belt tension to transfer rotational energy from the engine to the alternator. The Belt Tensioner is designed to automatically adjust the tension on the belt as it stretches or wears over time. This adjustment is vital for the alternator to generate a stable electrical output, which is used to charge the battery and power the vehicle’s electrical systems.

Moreover, the Belt Tensioner interacts with the drive mechanism to ensure smooth and reliable operation. It mitigates the effects of belt slippage, which can lead to inefficient power transfer and increased wear on both the belt and the alternator. By maintaining the appropriate tension, the Belt Tensioner contributes to the longevity and performance of the alternator and the overall drive system.

Conclusion

The integration of the 3967189 Belt Tensioner within the engine’s auxiliary systems is a testament to the intricate balance required for the seamless operation of vehicle components. Its role in sustaining the correct belt tension is fundamental to the alternator’s ability to perform its charging duties effectively.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.