This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

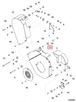

The Cummins 4095110 Belt Guard is a component designed to enhance the operation and reliability of heavy-duty trucks. This part plays a significant role in protecting auxiliary components within the truck’s mechanical systems. Manufactured by Cummins Inc., a well-established name in the automotive industry, the belt guard is part of a broader range of products known for their quality and performance 1.

Basic Concepts of Belt Guards

A belt guard is a protective enclosure that surrounds belt-driven components in mechanical systems. Its primary functions include safeguarding the belts from external contaminants, reducing noise, and preventing accidental contact with moving parts. In heavy-duty trucks, belt guards are essential for protecting auxiliary components such as alternators, water pumps, and air compressors. By integrating into the mechanical systems, belt guards contribute to the longevity and efficiency of these components 2.

Purpose of the 4095110 Belt Guard

The Cummins 4095110 Belt Guard is specifically designed to protect belt-driven components in heavy-duty trucks. It plays a role in shielding the belts from debris, moisture, and other environmental factors that could lead to wear and tear. By ensuring the belts operate in a controlled environment, the belt guard contributes to the overall efficiency and reliability of the truck’s auxiliary systems 3.

Key Features

The 4095110 Belt Guard boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear and corrosion. The design includes precise fitting elements that ensure a secure installation, minimizing the risk of displacement. Additionally, the belt guard is engineered to allow for easy access during maintenance, facilitating quick inspections and replacements when necessary.

Benefits

Using the Cummins 4095110 Belt Guard offers several benefits. It improves safety by reducing the risk of accidental contact with moving belts. It also contributes to reduced maintenance costs by protecting the belts from environmental damage, thereby extending their lifespan. Furthermore, the belt guard enhances the durability of belt-driven components, leading to increased reliability of the truck’s auxiliary systems.

Installation Process

Installing the 4095110 Belt Guard requires careful attention to detail to ensure optimal performance. The process involves several steps: first, ensure the truck’s engine is turned off and cooled down. Next, locate the belt-driven components that the guard will protect. Using the appropriate tools, carefully position the belt guard around the components, ensuring it fits securely. Finally, double-check the installation to confirm that the guard is properly aligned and does not interfere with the operation of the belts.

Troubleshooting and Maintenance

Common issues with the 4095110 Belt Guard may include displacement or damage due to impacts. Regular inspections are recommended to identify signs of wear or misalignment. If the guard shows signs of damage, it should be replaced to maintain the protection of the belt-driven components. Additionally, ensuring the guard remains clean and free from debris will contribute to its effective operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its diverse product range, which includes engines, filtration systems, and aftermarket parts designed to meet the demanding requirements of various applications.

Role of Part 4095110 Belt Guard in Engine Systems

The 4095110 Belt Guard is an essential component in safeguarding the belt-driven systems within various engine setups. Its primary function is to enclose and protect the belt, which is integral to the operation of several engine components.

Integration with Engine Components

-

Crankshaft and Flywheel: The Belt Guard ensures that the belt connecting the crankshaft to the flywheel remains intact and operates smoothly. This is vital for the consistent transfer of power from the engine to other mechanical components.

-

Alternator and Generator: In systems where the alternator or generator is belt-driven, the Belt Guard plays a significant role. It prevents the belt from coming into contact with other parts, reducing the risk of damage and ensuring efficient power generation.

-

Water Pump: Many engine systems use a belt to drive the water pump, which is essential for cooling the engine. The Belt Guard protects this belt, ensuring that the water pump operates without interruption, thereby maintaining optimal engine temperature.

-

Air Conditioning Compressor: In engines equipped with an air conditioning system, the compressor is often belt-driven. The Belt Guard helps in maintaining the integrity of the belt, ensuring that the air conditioning system functions correctly.

-

Power Steering Pump: For engines with a power steering system, the Belt Guard protects the belt that drives the power steering pump. This ensures that the steering remains responsive and easy to operate.

Additional Protective Functions

-

Debris and Contamination: The Belt Guard acts as a barrier against debris, dust, and other contaminants that could otherwise damage the belt or the components it drives.

-

Noise Reduction: By enclosing the belt, the Belt Guard also helps in reducing the noise generated by the belt’s operation, contributing to a quieter engine environment.

Conclusion

In summary, the 4095110 Belt Guard is a vital component in maintaining the efficiency and reliability of belt-driven systems within engine packages. Its protective role ensures that the interconnected components operate harmoniously, contributing to the overall performance of the engine.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.