This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

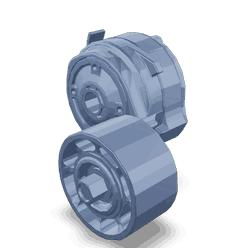

The Cummins 4316721 Belt Tensioner is a component designed for use in commercial trucks. Its purpose is to maintain the correct tension on the engine’s drive belts, which are essential for the operation of various engine accessories such as the alternator, water pump, and air conditioning compressor. Proper belt tension ensures these components operate efficiently and reliably.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at the optimal tension. It typically consists of a spring-loaded arm with a pulley that applies consistent pressure to the belt. Maintaining proper belt tension is important for several reasons: it prevents belt slippage, reduces wear on both the belt and the components it drives, and ensures efficient power transmission from the engine to the accessories 1.

Purpose of the 4316721 Belt Tensioner

The Cummins 4316721 Belt Tensioner plays a specific role in the operation of a truck by maintaining optimal belt tension for various engine components. This ensures that the belts do not become too loose, which could lead to slippage and inefficiency, or too tight, which could cause excessive wear and potential damage to the belts and pulleys.

Key Features

The Cummins 4316721 Belt Tensioner is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding commercial truck environments. The tensioner is engineered to provide consistent belt tension under varying engine loads and conditions, contributing to the reliable operation of engine accessories.

Benefits

Using the Cummins 4316721 Belt Tensioner offers several benefits. It contributes to improved engine efficiency by ensuring that drive belts operate at optimal tension, reducing the risk of slippage and wear. This, in turn, leads to reduced maintenance costs and enhanced overall reliability of the truck’s engine system. Additionally, proper belt tension helps in minimizing noise and vibration, contributing to a smoother engine operation 2.

Installation Process

Installing the Cummins 4316721 Belt Tensioner requires following a step-by-step process to ensure correct fitting and operation. The process involves removing the old tensioner, if present, and positioning the new tensioner in its place. Specific tools may be required to release the tension from the belt and to secure the tensioner in place. It is important to follow the manufacturer’s instructions closely to ensure the tensioner is installed correctly.

Maintenance Tips

Maintaining the Cummins 4316721 Belt Tensioner involves regular inspection routines to check for signs of wear or malfunction. This includes inspecting the tensioner for any visible damage, ensuring the belt remains at the correct tension, and listening for any unusual noises during engine operation that could indicate a problem. Recommended service intervals should be followed to ensure the tensioner continues to operate effectively.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 4316721 Belt Tensioner include tensioner failure, belt slippage, or noise during operation. Troubleshooting these problems involves inspecting the tensioner and belt for signs of wear, ensuring the tensioner is correctly installed, and checking that the belt is properly aligned and tensioned. Addressing these issues promptly can help prevent more serious problems and ensure the continued reliable operation of the engine system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The Cummins 4316721 Belt Tensioner is part of its extensive product range, designed to meet the demanding requirements of commercial truck applications.

Compatibility with Cummins Engines

The Belt Tensioner part 4316721, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is essential for maintaining the proper tension of the engine’s belts, ensuring optimal performance and longevity of the engine components.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The Belt Tensioner part 4316721 is compatible with the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, known for their reliability and efficiency in various applications, including heavy-duty trucks and industrial machinery.

Installation and Functionality

When installing the Belt Tensioner part 4316721 on these engines, it is essential to follow the manufacturer’s guidelines to ensure proper alignment and tension. This part works by applying the correct amount of force to keep the engine belts taut, preventing slippage and reducing wear on the belt and pulleys. Proper tensioning is vital for the efficient operation of the engine’s ancillary systems, such as the alternator, water pump, and air conditioning compressor.

Importance of Correct Part Usage

Using the correct Belt Tensioner part 4316721 is crucial for maintaining the engine’s performance and preventing potential failures. Cummins has designed this part to meet the specific requirements of the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines, ensuring compatibility and reliability. It is recommended to use genuine Cummins parts to maintain the warranty and performance standards of the engine.

Role in Engine Systems

In automotive and industrial engine systems, the 4316721 Belt Tensioner is a critical component that ensures the proper functioning of various driven components. This part is integral in maintaining the correct tension on the drive belts that connect to the compressor, refrigerant system, and air compressor.

Interaction with the Compressor

The compressor in an engine system is responsible for compressing the refrigerant, which is a key process in the cooling cycle of air conditioning systems. The 4316721 Belt Tensioner ensures that the drive belt connecting to the compressor is neither too loose nor too tight. Proper tension is vital for efficient power transmission from the engine to the compressor, ensuring optimal performance and longevity of the compressor.

Role in the Refrigerant System

In the refrigerant system, the 4316721 Belt Tensioner plays a supportive role by maintaining consistent belt tension. This consistency is important for the smooth operation of the refrigerant cycle. Any deviation in belt tension can lead to inefficient cooling, increased wear on the compressor, and potential system failures. The tensioner helps in absorbing the vibrations and shocks that occur during the operation, thereby protecting the refrigerant system components.

Drive System Integration

The drive system in an engine comprises various components that are powered by the engine’s rotational force. The 4316721 Belt Tensioner is positioned to manage the tension on the belts that drive these components. It ensures that the belts remain in optimal condition, reducing the risk of slippage or breakage. This is particularly important in high-stress environments where the drive system is constantly under load.

Functionality with the Air Compressor

An air compressor is another component that relies on the drive belt for operation. The 4316721 Belt Tensioner ensures that the belt driving the air compressor maintains the right tension. This is essential for the compressor to generate the required air pressure efficiently. Proper belt tension prevents unnecessary strain on the air compressor, leading to enhanced performance and durability.

Conclusion

The Cummins 4316721 Belt Tensioner is a vital component in engine systems, ensuring that the drive belts for the compressor, refrigerant system, and air compressor operate within the optimal tension range. This not only enhances the efficiency of these components but also contributes to their longevity and reliable performance 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.