This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4320327 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying consistent pressure to the belt, which helps in the smooth transfer of power to components such as the alternator, water pump, and air conditioning compressor. Maintaining proper belt tension is important for the longevity and efficiency of these components, as well as for the overall performance of the engine 1.

Purpose of the Cummins 4320327 Belt Tensioner

The Cummins 4320327 Belt Tensioner is specifically designed to maintain optimal belt tension in the operation of a truck. It ensures that the belts driving various engine components are neither too loose nor too tight, which can lead to slippage or excessive wear. By maintaining the correct tension, the tensioner contributes to the reliable and efficient operation of the truck’s engine system.

Key Features

The Cummins 4320327 Belt Tensioner is constructed with high-quality materials to ensure durability and performance. Its design includes a spring-loaded mechanism that automatically adjusts to maintain the correct belt tension. The tensioner is built to withstand the rigors of commercial truck operation, featuring a robust construction that enhances its longevity and reliability.

Benefits

The Cummins 4320327 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that belts operate within their optimal tension range. This reduces wear on both the belts and the pulleys they drive. Additionally, the tensioner enhances the overall reliability of the truck’s engine system by preventing issues related to belt slippage or tension imbalance 2.

Installation

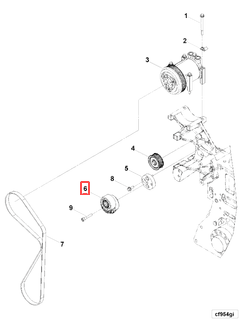

Installing the Cummins 4320327 Belt Tensioner requires following a series of steps to ensure proper fit and function. The process involves securing the tensioner in place, connecting it to the belt, and adjusting it to the correct tension. Specific tools may be required, and safety precautions should be observed to prevent injury or damage during installation.

Maintenance and Troubleshooting

To ensure the Cummins 4320327 Belt Tensioner operates optimally, regular maintenance is recommended. This includes inspecting the tensioner for signs of wear or damage, ensuring the belt remains at the correct tension, and addressing any issues promptly. Troubleshooting common problems, such as belt slippage or unusual noises, can often be resolved by adjusting the tensioner or replacing worn components.

Common Issues and Solutions

Common issues with the Cummins 4320327 Belt Tensioner may include belt slippage, tensioner wear, or failure. Solutions to these problems can range from adjusting the tensioner to replacing worn parts. Preventive measures, such as regular inspections and maintenance, can help avoid these issues and ensure the tensioner continues to operate effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry for quality and innovation, Cummins is committed to providing reliable and efficient components for a wide range of applications, including commercial trucks. The company’s focus on quality and customer satisfaction is evident in its product offerings, including the Cummins 4320327 Belt Tensioner.

Compatibility with Specific Engine Models

The Belt tensioner part 4320327, manufactured by Cummins, is designed to be compatible with a range of engine models. Specifically, it fits with the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102 engines. This part is crucial for maintaining the proper tension of the engine’s belt, ensuring efficient operation and longevity of the belt and associated components.

For the ISZ13 CM2150 Z105 engine, the Belt tensioner part 4320327 is engineered to integrate seamlessly, providing the necessary tension to the belt that drives various engine accessories. Its design ensures that the belt remains taut, reducing the risk of slippage and enhancing the overall performance of the engine.

Similarly, the QSZ13 CM2150 Z102 engine also benefits from the use of the Belt tensioner part 4320327. This part is specifically tailored to fit the unique requirements of this engine model, ensuring that the belt maintains optimal tension, which is critical for the efficient operation of the engine’s ancillary systems.

Both engines, ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102, rely on the Belt tensioner part 4320327 to ensure that the belt remains properly tensioned, which is essential for the smooth and reliable operation of the engine. This part is a key component in maintaining the integrity of the engine’s belt system, contributing to the overall performance and durability of the engine.

Role of Part 4320327 Belt Tensioner in Engine Systems

The part 4320327 Belt tensioner is integral to maintaining the proper function and efficiency of various engine components through its role in the belt drive system.

Compressor

In systems where a compressor is present, the belt tensioner ensures that the drive belt remains taut. This tautness is essential for the compressor to operate efficiently, as it relies on consistent belt tension to compress the refrigerant. Without adequate tension, the compressor may not receive the necessary power transfer from the engine, leading to inefficient cooling performance.

Refrigerant System

The refrigerant system benefits indirectly from the belt tensioner’s role. By maintaining optimal belt tension, the tensioner supports the compressor’s ability to circulate refrigerant effectively. This circulation is vital for the air conditioning system’s cooling efficiency, ensuring that the refrigerant is compressed and expanded in a controlled manner to achieve the desired cooling effect.

Mounting

The mounting of the belt tensioner itself is designed to allow for adjustments in belt tension as the engine and its components undergo wear and thermal expansion. Proper mounting ensures that the tensioner can move freely to maintain the correct belt tension under varying operating conditions.

Fan Drive

In engines equipped with a fan drive system, the belt tensioner plays a significant role in ensuring that the fan operates efficiently. The fan drive relies on a consistent belt tension to move air through the radiator and other cooling components. The tensioner helps in maintaining this tension, which is essential for effective engine cooling and preventing overheating.

Overall, the part 4320327 Belt tensioner is a key component in the engine’s belt drive system, supporting the efficient operation of the compressor, refrigerant system, and fan drive, while its proper mounting ensures adaptability to changing conditions.

Conclusion

The Cummins 4320327 Belt Tensioner plays a crucial role in maintaining the efficiency and reliability of commercial truck engines. By ensuring optimal belt tension, it supports the smooth operation of various engine components, contributing to the overall performance and longevity of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.