This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

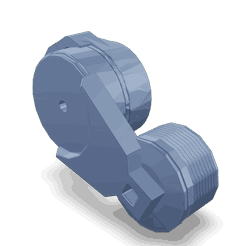

The Cummins 4939368 Belt Tensioner is a component designed for use in commercial trucks. It ensures that the drive belts within the engine system maintain the correct tension, which is vital for the efficient transfer of power to auxiliary components such as the alternator, water pump, and air conditioning compressor 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at optimal tension. It typically consists of a spring-loaded arm with a pulley that applies consistent pressure to the belt. This pressure ensures that the belt does not slip or become too loose, which could lead to inefficient power transfer and increased wear on the belt and pulleys 2.

Purpose of the Cummins 4939368 Belt Tensioner

The Cummins 4939368 Belt Tensioner is engineered to maintain the correct tension on the drive belts in a truck’s engine. It ensures that the belts operate efficiently and do not slip, which could lead to decreased performance and potential damage to engine components. The tensioner helps in distributing the load evenly across the belt, reducing the risk of premature wear and tear 3.

Key Features

The Cummins 4939368 Belt Tensioner is characterized by its robust design and the use of high-quality materials. It features a durable construction that can withstand the harsh conditions often encountered in commercial truck operations. The tensioner is equipped with a precision-machined pulley and a high-strength spring, which contribute to its reliable performance and longevity. Additionally, it is designed to accommodate the specific requirements of Cummins engines, ensuring optimal functionality 4.

Benefits of Using the Cummins 4939368 Belt Tensioner

Utilizing the Cummins 4939368 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that the drive belts operate at the correct tension. This results in reduced wear on the belts and pulleys, leading to longer service intervals and decreased maintenance costs. Furthermore, the tensioner enhances the reliability of the engine system by preventing belt slippage and the associated performance issues 5.

Installation and Compatibility

Proper installation of the Cummins 4939368 Belt Tensioner is important for its effective operation. It is designed to be compatible with a range of Cummins engine models, ensuring a seamless integration into the engine system. Installation procedures should follow the manufacturer’s guidelines to ensure that the tensioner is correctly positioned and secured. This will help in achieving the desired belt tension and maintaining the efficiency of the engine system 6.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4939368 Belt Tensioner is important for its continued performance. This includes periodic inspections to check for signs of wear or damage, such as cracks in the pulley or signs of spring fatigue. Addressing these issues promptly can help in preventing more serious problems down the line. Troubleshooting common issues, such as belt slippage or unusual noises, may involve adjusting the tensioner or replacing worn components 7.

Common Failure Modes

Belt tensioners can experience several types of failure, including spring fatigue, bearing wear, and belt slippage. Spring fatigue can occur over time due to the constant loading and unloading of the spring, while bearing wear may result from inadequate lubrication or excessive load. Belt slippage can be caused by incorrect tension or wear on the belt itself. Preventive measures, such as regular maintenance and proper installation, can help in mitigating these failure modes 8.

Replacement Procedures

Replacing a faulty Cummins 4939368 Belt Tensioner involves several steps. It is important to use the appropriate tools and follow safety precautions to ensure a successful replacement. The process typically includes removing the old tensioner, installing the new one in its place, and ensuring that it is correctly aligned and secured. Reassembly should be done in accordance with the manufacturer’s guidelines to maintain the efficiency and reliability of the engine system 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes engines, filtration systems, and other power-related technologies, all designed to meet the demanding requirements of commercial applications 10.

Belt Tensioner 4939368 Compatibility with Cummins Engines

The Belt Tensioner part number 4939368, manufactured by Cummins, is designed to fit a variety of their engine models. This part plays a role in maintaining the proper tension of the engine’s belts, ensuring efficient operation and longevity of the engine components.

B6.7 and B125 Engines

The Belt Tensioner 4939368 is compatible with the B6.7 and B125 engines. These engines are part of the Cummins lineup and are known for their robust performance and reliability. The belt tensioner ensures that the belts remain taut, preventing slippage and maintaining the necessary tension for optimal power transfer and accessory operation 11.

ISB/ISD 4.5 and 6.7 Engines

For the ISB/ISD 4.5 and 6.7 engines, the Belt Tensioner 4939368 is a component. These engines are widely used in various applications, from heavy-duty trucks to industrial machinery. The belt tensioner’s role in these engines is to maintain the correct tension on the belts that drive essential accessories such as the alternator, water pump, and air conditioning compressor 12.

ISB/ISD 4.5 CM2150 and ISB/ISD 6.7 CM2150

Specifically, the ISB/ISD 4.5 CM2150 and ISB/ISD 6.7 CM2150 engines benefit from the precise tensioning provided by the 4939368 belt tensioner. This ensures that the belts operate efficiently, reducing wear and tear on the components they drive 13.

ISBE and ISBE4 Engines

The Belt Tensioner 4939368 is also compatible with the ISBE and ISBE4 engines. These engines are designed for on-highway applications and are known for their high performance and fuel efficiency. The belt tensioner ensures that the belts remain properly tensioned, which is important for the efficient operation of the engine’s accessories 14.

ISL9 Engine

The ISL9 engine is another model that can utilize the Belt Tensioner 4939368. This engine is designed for heavy-duty applications and is known for its durability and power. The belt tensioner ensures that the belts remain taut, preventing slippage and maintaining the necessary tension for optimal accessory operation 15.

SN Engines

Lastly, the Belt Tensioner 4939368 is compatible with the SN engines, including the ISB4.5 CM2350 and ISB6.7 CM2350 models. These engines are part of the Cummins SN series, which is known for its versatility and reliability in various applications. The belt tensioner ensures that the belts remain properly tensioned, which is important for the efficient operation of the engine’s accessories 16.

Role of Part 4939368 Belt Tensioner in Engine Systems

In the orchestration of an engine’s auxiliary systems, the part 4939368 Belt Tensioner assumes a significant role. This component is integral to the proper functioning of the belt-driven accessories, which include the alternator, water pump, power steering pump, and air conditioning compressor, among others.

The Belt Tensioner operates on a simple yet effective principle: it maintains the correct tension on the belt that drives these accessories. Without adequate tension, the belt could slip, leading to inefficient operation of the accessories and potential damage to the belt itself.

When the engine is running, the Belt Tensioner automatically adjusts to keep the belt at the optimal tension, compensating for the natural stretch that occurs over time and ensuring consistent performance. This is particularly important in variable-speed systems where the accessories do not operate at a constant speed.

Moreover, the Belt Tensioner is designed to absorb vibrations and reduce noise, contributing to a smoother and quieter engine operation. It also plays a part in prolonging the life of the belt by preventing it from becoming overly tight, which could cause premature wear, or too loose, which could lead to slippage and overheating.

In summary, the part 4939368 Belt Tensioner is a key player in the symphony of engine components, ensuring that the belt-driven accessories operate efficiently and reliably, while also contributing to the overall smoothness and longevity of the engine system 17.

Conclusion

The Cummins 4939368 Belt Tensioner is a critical component in the maintenance and efficiency of commercial truck engines. By ensuring the correct tension of drive belts, it contributes to the reliable operation of auxiliary components and the overall performance of the engine system. Proper installation, regular maintenance, and understanding of common failure modes are essential for maximizing the benefits of this Cummins part.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). About Cummins. Retrieved from https://www.cummins.com/about

↩ -

Cummins Inc. (n.d.). B6.7 and B125 Engines. Retrieved from https://www.cummins.com/engines

↩ -

Cummins Inc. (n.d.). ISB/ISD 4.5 and 6.7 Engines. Retrieved from https://www.cummins.com/engines

↩ -

Cummins Inc. (n.d.). ISB/ISD 4.5 CM2150 and ISB/ISD 6.7 CM2150 Engines. Retrieved from https://www.cummins.com/engines

↩ -

Cummins Inc. (n.d.). ISBE and ISBE4 Engines. Retrieved from https://www.cummins.com/engines

↩ -

Cummins Inc. (n.d.). ISL9 Engine. Retrieved from https://www.cummins.com/engines

↩ -

Cummins Inc. (n.d.). SN Engines. Retrieved from https://www.cummins.com/engines

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.