This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

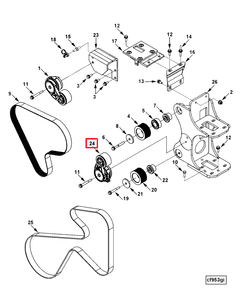

The Cummins 5270452 Belt Tensioner is a critical component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the smooth operation of various engine-driven accessories, which are vital for the overall functionality and efficiency of the vehicle 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying consistent pressure to the belt, which prevents slippage and ensures that power is efficiently transmitted from the engine to other components such as the alternator, water pump, and air conditioning compressor. Maintaining proper belt tension is important for the longevity of the belts and the reliable operation of the engine system 2.

Purpose of the Cummins 5270452 Belt Tensioner

This Cummins part plays a role in the operation of a truck by maintaining optimal belt tension. This ensures that the belts drive the engine accessories effectively without slipping, which could lead to inefficient power transmission and increased wear on the belts and pulleys 3.

Key Features

The 5270452 is characterized by its robust design and the quality materials used in its construction. These features contribute to its performance and durability, allowing it to withstand the demanding conditions of commercial truck operations.

Benefits

Using this part is associated with several benefits. These include improved engine performance due to efficient power transmission, reduced wear on belts leading to longer service intervals, and enhanced reliability of the engine system.

Installation and Compatibility

Proper installation of the 5270452 involves following specific guidelines to ensure it functions correctly within the engine system. It is designed to be compatible with certain truck models and engine types, which should be considered during the installation process.

Maintenance and Troubleshooting

Routine maintenance practices for the 5270452 include regular inspections for signs of wear or damage and ensuring that the tensioner operates smoothly. Common troubleshooting tips involve addressing issues such as belt slippage or tensioner malfunctions promptly to prevent further complications.

Performance and Efficiency

The 5270452 contributes to overall engine performance and fuel efficiency in commercial trucks by ensuring that belts operate at the correct tension. This leads to efficient power transmission and reduces the load on the engine, which can improve fuel economy.

Safety Considerations

When working with the 5270452, it is important to observe safety protocols and precautions. This includes proper handling during installation and maintenance, as well as following manufacturer guidelines to ensure the component operates safely and effectively.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the automotive and heavy-duty truck industry. Known for its commitment to quality and innovation, Cummins has built a reputation for producing reliable and high-performance engine components, including the 5270452.

Belt Tensioner Part 5270452 Compatibility with Cummins Engines

The Belt Tensioner part number 5270452, manufactured by Cummins, is a critical component in maintaining the operational integrity of various engine systems. This part is designed to ensure that the engine’s belts are held at the correct tension, which is essential for the proper functioning of the engine’s ancillary systems, such as the alternator, water pump, and air conditioning compressor.

ISL9 CM2150 SN

The ISL9 CM2150 SN engine is a high-performance, heavy-duty diesel engine that is widely used in various applications, including on-highway and off-highway vehicles. The Belt Tensioner part 5270452 is specifically engineered to fit this engine model, ensuring that the belts are maintained at the optimal tension levels required for efficient operation. This part is crucial in preventing belt slippage, which can lead to reduced efficiency and potential damage to the engine’s components.

QSX15 CM2350 X105

The QSX15 CM2350 X105 engine is another robust and reliable engine model from Cummins, known for its durability and performance in demanding environments. The Belt Tensioner part 5270452 is designed to seamlessly integrate with this engine, providing the necessary tension to the belts that drive the engine’s ancillary systems. This ensures that the engine operates smoothly and efficiently, with minimal wear and tear on the belts and related components.

Grouping of Engines

Both the ISL9 CM2150 SN and QSX15 CM2350 X105 engines are part of Cummins’ lineup of high-performance, heavy-duty diesel engines. These engines are designed to deliver exceptional power and reliability, making them suitable for a wide range of applications, from on-highway to off-highway use. The Belt Tensioner part 5270452 is compatible with both engine models, ensuring that the belts are held at the correct tension, which is essential for maintaining the engine’s performance and longevity.

Role of Part 5270452 Belt Tensioner in Engine Systems

The part 5270452 Belt Tensioner is an integral component in maintaining the efficiency and reliability of various engine systems. It ensures that the belts driving multiple components are kept at the optimal tension, which is essential for the smooth operation of these systems.

Interaction with the Compressor

In systems where a compressor is present, the Belt Tensioner plays a significant role. It maintains the necessary tension on the belt that drives the compressor. This ensures that the compressor operates efficiently, providing consistent refrigerant flow. Proper tension prevents slippage, which could lead to inefficient cooling and increased wear on the compressor.

Ensuring Refrigerant System Efficiency

The refrigerant system relies on the compressor to circulate refrigerant. The Belt Tensioner, by maintaining optimal belt tension, ensures that the compressor can perform its function without interruption. This leads to a more reliable refrigerant system, which is vital for maintaining the desired temperature in various applications.

Secure Mounting and Stability

The mounting of the Belt Tensioner is designed to provide stability and reduce vibrations. This is particularly important in high-stress environments where engine components are subject to significant forces. Stable mounting ensures that the tensioner can perform its function effectively over time, contributing to the longevity of the belt and the components it drives.

Supporting the Alternator

The alternator is another component that benefits from the Belt Tensioner. By keeping the belt taut, the tensioner ensures that the alternator receives consistent power to generate electricity. This is essential for charging the battery and powering electrical systems within the engine. Proper tension prevents the alternator from overworking, which can lead to premature failure.

Overall System Integration

The Belt Tensioner integrates seamlessly with these components, ensuring that each one operates within its designed parameters. This not only enhances the performance of individual components but also contributes to the overall efficiency of the engine system. The tensioner’s role in maintaining belt tension is a fundamental aspect of engine maintenance and performance.

Conclusion

The Cummins 5270452 Belt Tensioner is a vital component in the maintenance and operation of commercial truck engines. Its role in maintaining optimal belt tension ensures the efficient operation of engine-driven accessories, contributing to the overall performance, reliability, and fuel efficiency of the vehicle. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.