This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

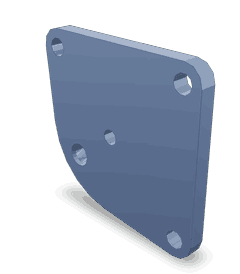

The Cummins 5271095 Belt Tensioner Bracket is a component designed to support the proper functioning of belts within the engine system of commercial trucks. Its purpose is to maintain the correct tension on the belts, which is vital for the efficient operation of various engine-driven accessories. This part plays a significant role in ensuring that the belts perform their functions without slipping or excessive wear, contributing to the overall reliability and performance of the truck.

Function and Operation

The Belt Tensioner Bracket operates by providing a stable mounting point for the tensioner mechanism within the truck’s engine system. It ensures that the tensioner can apply the necessary force to keep the belts at the optimal tension. This is achieved through a combination of mechanical design and material properties that allow the bracket to withstand the dynamic forces encountered during engine operation 1. By maintaining proper belt tension, the bracket helps in the efficient transfer of power to components such as the alternator, water pump, and air conditioning compressor.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. It is typically made from durable metals that offer resistance to corrosion and wear. The bracket is engineered to provide a secure fit within the engine compartment, ensuring that it can endure the vibrations and thermal cycles experienced during truck operation 2. Additionally, its design may include features such as alignment guides or mounting tabs to facilitate easy and accurate installation.

Role in Truck Operation

In the operation of a commercial truck, the Belt Tensioner Bracket plays a specific role by ensuring that the belts connected to the engine’s accessories are kept under the correct tension. This is important for the consistent performance of these accessories, which in turn affects the truck’s overall efficiency and reliability. The bracket works in conjunction with the tensioner and the belts to create a system that can adapt to the varying loads and conditions encountered during truck operation.

Benefits

The 5271095 offers several advantages. It contributes to improved engine efficiency by ensuring that the belts operate within their designed parameters, reducing the risk of slippage or failure. This can lead to enhanced durability of the belts and the accessories they drive. Additionally, by maintaining optimal belt tension, the bracket helps in minimizing wear on the belts, which can extend their service life and reduce the frequency of replacements 3.

Installation Process

Installing the Belt Tensioner Bracket requires careful attention to ensure it is correctly fitted. The process typically involves loosening the existing tensioner to allow the belts to be removed, positioning the bracket in its designated location, and securing it with the appropriate fasteners. It is important to follow the manufacturer’s instructions regarding torque specifications for the fasteners to ensure the bracket is properly secured. Once the bracket is in place, the belts can be re-installed, and the tensioner can be adjusted to the correct tension.

Maintenance and Troubleshooting

Regular maintenance of the Belt Tensioner Bracket includes inspecting it for signs of wear, corrosion, or damage. It is also important to check that the bracket is securely fastened and that the tensioner is functioning correctly. Common issues may include loose fasteners, worn brackets, or tensioners that are not applying the correct force. Addressing these issues promptly can help prevent more serious problems with the engine’s accessory drive system.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, components, and technologies that power commercial vehicles, equipment, and power generation systems. Cummins is committed to delivering value to its customers through a combination of performance, efficiency, and durability in its products.

Belt Tensioner Bracket 5271095 Compatibility with Cummins Engines

The Belt Tensioner Bracket 5271095, manufactured by Cummins, is a critical component designed to ensure the proper tensioning of belts in various engine configurations. This part is engineered to fit seamlessly with several Cummins engines, ensuring optimal performance and longevity of the belt system.

QSB3.3 CM2250 EC

The QSB3.3 CM2250 EC is one of the engines that benefit from the Belt Tensioner Bracket 5271095. This engine is known for its robust design and reliability, making it a popular choice in various industrial applications. The bracket’s precise fit and robust construction ensure that the belt system operates efficiently, reducing the risk of belt slippage and wear.

Group Compatibility

The Belt Tensioner Bracket 5271095 is also compatible with a range of other Cummins engines within the same group. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. By ensuring that the bracket fits multiple engines, Cummins simplifies maintenance and repair processes, allowing for easier part replacement and reducing downtime.

By integrating the Belt Tensioner Bracket 5271095 into these engines, Cummins maintains the high standards of performance and reliability that its customers expect. This compatibility underscores the versatility and robustness of the bracket, making it a valuable component for maintaining the integrity of the belt system in various engine applications.

Role of Part 5271095 Belt Tensioner Bracket in Engine Systems

The part 5271095 Belt Tensioner Bracket is an integral component in maintaining the proper function of the belt tensioner within various engine systems. This bracket securely mounts the belt tensioner to the engine block or other structural components, ensuring that the tensioner remains in the correct position and orientation.

When the engine is running, the belt tensioner, which is mounted using the 5271095 Belt Tensioner Bracket, applies the necessary force to keep the serpentine belt or timing belt properly tensioned. This tension is vital for the efficient transfer of power from the crankshaft to other engine components such as the alternator, water pump, power steering pump, and air conditioning compressor.

The 5271095 Belt Tensioner Bracket also plays a role in accommodating the natural movement and vibrations of the engine. By providing a stable mounting point, it helps to reduce wear and tear on the belt tensioner and the belt itself, contributing to the longevity and reliability of the engine’s auxiliary systems 4.

Conclusion

In summary, the 5271095 Belt Tensioner Bracket ensures that the belt tensioner operates effectively within the engine system, maintaining the correct tension on the belts and supporting the smooth and efficient function of all connected components. Its robust design, compatibility with various Cummins engines, and role in maintaining optimal belt tension make it a critical component for the reliability and performance of commercial trucks.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Kasab, John, and Strzelec, Andrea. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Huzij, Robert, Spano, Angelo, and Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.