5291974

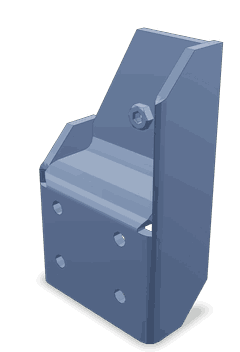

Belt Tensioner Bracket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5291974 Belt Tensioner Bracket, manufactured by Cummins, is a critical component in the operation of commercial trucks. This part ensures the efficient functioning of belts and pulleys within the engine system. Cummins, a renowned manufacturer in the commercial truck industry, is known for producing reliable and high-quality parts, and the 5291974 Belt Tensioner Bracket is no exception 1.

Basic Concepts of Belt Tensioner Brackets

A Belt Tensioner Bracket serves as a mounting point for the belt tensioner, which maintains the correct tension on the engine’s drive belts. These belts are essential for the operation of various engine components, such as the alternator, water pump, and air conditioning compressor. The tensioner bracket ensures that the tensioner is securely positioned and can effectively adjust the tension on the belts as needed. This interaction is vital for the smooth and efficient operation of the engine system 2.

Purpose of the 5291974 Belt Tensioner Bracket

The 5291974 Belt Tensioner Bracket is designed to support the belt tensioner in maintaining the appropriate tension on the drive belts. Proper belt tension is necessary for efficient power transmission from the engine to the various components it drives. This bracket plays a role in ensuring that the belts operate within their optimal tension range, which helps in reducing wear and tear, preventing belt slippage, and ensuring the reliable operation of engine-driven accessories 3.

Key Features

The 5291974 Belt Tensioner Bracket is constructed with durability and performance in mind. It is made from high-quality materials that can withstand the rigors of commercial truck operation. The design includes features such as precise mounting points for secure installation and compatibility with a variety of belt tensioners. Additionally, the bracket may incorporate design elements that enhance its resistance to vibration and environmental factors, contributing to its longevity and reliable performance.

Benefits

The use of the 5291974 Belt Tensioner Bracket offers several advantages. It contributes to improved belt life by ensuring consistent and proper tension, which reduces the likelihood of belt failure. This, in turn, leads to reduced maintenance requirements, as belts that are properly tensioned are less likely to need adjustment or replacement. Furthermore, the efficient operation of the drive belts, facilitated by the tensioner bracket, can enhance overall engine performance by ensuring that engine-driven accessories receive the necessary power transmission.

Installation Process

Installing the 5291974 Belt Tensioner Bracket requires careful attention to detail to ensure proper fitting and function. The process involves securing the bracket to the engine using the provided mounting hardware. It is important to follow the manufacturer’s instructions regarding torque specifications for the mounting bolts to ensure a secure fit. Additionally, the alignment of the bracket with the belt tensioner and the drive belts must be checked to ensure optimal performance. The use of appropriate tools, such as a torque wrench, may be necessary to complete the installation process correctly.

Troubleshooting Common Issues

Common issues associated with Belt Tensioner Brackets can include noise, vibration, or belt slippage. These problems may arise from improper installation, wear and tear, or environmental factors. Troubleshooting steps may involve inspecting the bracket and tensioner for signs of damage or misalignment, checking the tension of the belts, and ensuring that the bracket is securely mounted. Addressing these issues promptly can help maintain the efficient operation of the engine system.

Maintenance Tips

Regular maintenance of the 5291974 Belt Tensioner Bracket is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, such as cracks or corrosion, and ensuring that the mounting bolts remain tight. Additionally, monitoring the condition of the drive belts and adjusting the tension as necessary can help prevent issues related to belt slippage or failure. Following the manufacturer’s recommended maintenance intervals can contribute to the reliable operation of the tensioner bracket and the engine system as a whole.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a trusted choice for commercial truck operators and manufacturers alike. The 5291974 Belt Tensioner Bracket, as a product of Cummins, benefits from the company’s expertise and dedication to producing high-quality components for the automotive and heavy-duty truck sectors.

Belt Tensioner Bracket 5291974 Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 5291974, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This bracket plays a role in maintaining the proper tension of the engine’s serpentine belt, ensuring efficient power transmission and optimal performance.

ISL G CM2180 Engines

The ISL G CM2180 engines are part of Cummins’ lineup of high-performance, heavy-duty diesel engines. The Belt Tensioner Bracket 5291974 is specifically engineered to fit these engines, providing a reliable and durable solution for maintaining belt tension. This compatibility ensures that the engine operates smoothly and efficiently, reducing the risk of belt slippage or failure.

Group Compatibility

In addition to the ISL G CM2180 engines, the Belt Tensioner Bracket 5291974 is also compatible with other Cummins engine models within the same group. This broad compatibility allows for easier maintenance and repair, as the same part can be used across multiple engine types. This not only simplifies inventory management for service providers but also ensures that the correct part is readily available when needed.

By ensuring that the Belt Tensioner Bracket 5291974 fits a range of Cummins engines, including the ISL G CM2180 and other compatible models, Cummins maintains a high standard of quality and reliability in their engine components. This compatibility is a testament to Cummins’ commitment to providing durable and efficient solutions for their customers.

Role of Part 5291974 Belt Tensioner Bracket in Engine Systems

The part 5291974 Belt Tensioner Bracket is an integral component in maintaining the optimal operation of various engine systems. It is strategically positioned to interact with several key components, ensuring the efficient transfer of power and the smooth functioning of the engine.

Interaction with the Alternator

The Belt Tensioner Bracket works in conjunction with the alternator by maintaining the correct tension on the drive belt. This ensures that the alternator receives a consistent rotational force, which is essential for generating electricity to power the vehicle’s electrical systems and recharge the battery. Proper tension prevents slippage, which could lead to inefficient power generation and potential damage to the alternator.

Mounting and Stability

The Bracket is mounted securely to the engine block or chassis, providing a stable foundation for the tensioner mechanism. This mounting point is critical for absorbing the dynamic forces generated during engine operation. The stability offered by the Bracket ensures that the tensioner can effectively manage the belt’s tension across varying engine speeds and loads, contributing to the longevity and reliability of the belt and associated components.

Overall System Integration

By ensuring the drive belt remains taut, the Belt Tensioner Bracket plays a role in the coordinated function of the engine’s auxiliary systems. This includes not only the alternator but also other components such as the water pump, air conditioning compressor, and power steering pump. Each of these components relies on the consistent and proper tension of the drive belt to operate efficiently, highlighting the Bracket’s importance in the overall engine system.

Conclusion

The 5291974 Belt Tensioner Bracket is a vital component in the operation of commercial trucks, ensuring the efficient functioning of belts and pulleys within the engine system. Manufactured by Cummins, this part is designed to support the belt tensioner in maintaining the appropriate tension on the drive belts, contributing to reduced wear and tear, preventing belt slippage, and ensuring the reliable operation of engine-driven accessories. Its compatibility with various Cummins engine models, including the ISL G CM2180, underscores Cummins’ commitment to quality and reliability in their engine components.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.