This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

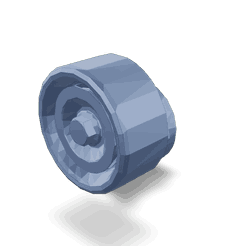

The 5302528 Belt Tensioner by Cummins is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying consistent pressure to the belt, which helps in reducing slippage and wear. Proper belt tension is important for the efficient transfer of power from the engine to components such as the alternator, water pump, and air conditioning compressor 1.

Purpose of the 5302528 Belt Tensioner

This part plays a role in the operation of a truck by maintaining optimal belt tension. This ensures that the belts drive engine components effectively, which contributes to the overall performance and reliability of the truck. By keeping the belts properly tensioned, it helps in reducing the risk of belt failure and enhances the efficiency of the engine system 2.

Key Features

The 5302528 Belt Tensioner is characterized by several design elements that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear and corrosion. The tensioner features a robust design that can withstand the demanding conditions of commercial truck applications. Additionally, it includes precision-machined components that ensure smooth operation and consistent belt tension 3.

Benefits of Using the 5302528 Belt Tensioner

Using this Cummins part offers several advantages. It contributes to improved engine efficiency by ensuring that belts operate at the optimal tension. This reduces wear on the belts and the components they drive, leading to enhanced reliability. The tensioner’s durable construction and precise engineering make it well-suited for the rigors of commercial truck use 4.

Installation Process

Installing the 5302528 Belt Tensioner involves several steps to ensure proper function. The process begins with the removal of the old tensioner, if applicable. The new tensioner is then positioned in place, and any mounting brackets or fasteners are secured. It is important to follow the manufacturer’s instructions for torque specifications and alignment to ensure the tensioner operates correctly. Specific tools may be required for certain steps, such as belt tensioning tools or socket wrenches.

Maintenance Tips

To ensure the optimal performance and longevity of this part, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Lubrication of moving parts, if applicable, can help in reducing friction and wear. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help in maintaining the tensioner’s effectiveness.

Troubleshooting Common Issues

Common problems associated with belt tensioners can include noise, slippage, or premature wear. These issues may be caused by improper installation, lack of maintenance, or normal wear over time. Troubleshooting steps may involve inspecting the tensioner for damage, ensuring proper belt tension, and checking for alignment issues. Solutions may include re-tensioning the belt, lubricating moving parts, or replacing worn components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of power solutions, including engines, filtration, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product offerings are known for their reliability, performance, and durability, making them a preferred choice for commercial vehicle applications.

Belt Tensioner Part 5302528 Compatibility with Cummins Engines

The Belt Tensioner part number 5302528, manufactured by Cummins, is designed to fit seamlessly with several Cummins engine models. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring optimal performance and longevity of the engine components.

QSF2.8 CM2880 F108 Engines

The Belt Tensioner part 5302528 is compatible with the QSF2.8 CM2880 F108 engines. This compatibility ensures that the tensioner can effectively manage the belt’s tension, preventing slippage and reducing wear on the belt and pulleys. The design of this part is engineered to fit precisely within the engine’s layout, ensuring ease of installation and reliable operation.

Grouping of Compatible Engines

While the specific engines mentioned above are compatible with the Belt Tensioner part 5302528, it is important to note that this part may also fit other similar Cummins engines. The design and specifications of the tensioner are crafted to ensure it can be used across a range of engine models, providing a versatile solution for maintaining belt tension in various applications.

By ensuring the Belt Tensioner part 5302528 is correctly installed, engine operators can maintain the efficiency and reliability of their engines, avoiding potential issues related to belt slippage or failure.

Role of Part 5302528 Belt Tensioner in Engine Systems

The part 5302528 Belt Tensioner is an integral component in maintaining the optimal performance of various engine systems. It ensures that the tensioner belt is properly tensioned, which is essential for the efficient operation of several engine-driven accessories.

Interaction with Engine-Driven Accessories

The Belt Tensioner works in conjunction with the tensioner belt to provide the necessary tension for driving components such as the alternator, water pump, power steering pump, and air conditioning compressor. Proper tensioning ensures that these accessories receive consistent power transmission from the engine, which is vital for their reliable operation.

Ensuring Smooth Operation

By maintaining the correct tension on the tensioner belt, the Belt Tensioner helps to minimize slippage and wear on the belt. This results in smoother operation of the engine systems, reduced noise, and enhanced durability of the belt and the driven components.

Facilitating Maintenance and Replacement

The Belt Tensioner also plays a significant role during maintenance and replacement procedures. It allows for easy adjustment of the tensioner belt, making it simpler to install or remove the belt without the need for complex tools or procedures. This facilitates routine maintenance and ensures that the engine systems can be serviced efficiently.

Supporting Engine Efficiency

Proper tensioning of the tensioner belt by the Belt Tensioner contributes to overall engine efficiency. It ensures that the engine-driven accessories operate within their designed parameters, which can lead to improved fuel efficiency and reduced strain on the engine.

Enhancing Component Longevity

By ensuring consistent tension on the tensioner belt, the Belt Tensioner helps to extend the lifespan of both the belt and the driven components. This reduces the frequency of replacements and repairs, leading to lower maintenance costs and increased reliability of the engine systems.

Conclusion

The 5302528 Belt Tensioner by Cummins is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its proper installation and maintenance are essential for ensuring the optimal performance of engine-driven accessories and the overall engine system.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.