5333482

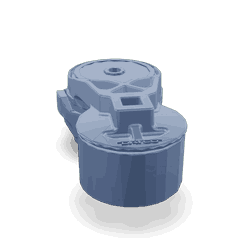

Belt Tensioner

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5333482 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as the alternator, water pump, and air conditioning compressor. Proper belt tension is essential for the optimal performance and longevity of these components 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying consistent pressure to the belt, which prevents slippage and ensures that power is efficiently transmitted from the engine to the driven accessories. Maintaining proper belt tension is important for the reliable operation of the engine system, as it reduces wear on the belts and enhances the performance of the accessories they drive 2.

Purpose of the Cummins 5333482 Belt Tensioner

The Cummins 5333482 Belt Tensioner plays a role in the operation of a truck by maintaining optimal belt tension. This ensures that the belts drive their respective accessories efficiently, which is vital for the overall performance of the engine. By keeping the belts properly tensioned, the tensioner helps to minimize wear and tear, reduce the risk of belt failure, and contribute to the smooth operation of the truck 3.

Key Features

The Cummins 5333482 Belt Tensioner is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and performance. The tensioner is engineered to withstand the demanding conditions of commercial truck operations, ensuring reliable performance over time. Its design may include features such as a spring-loaded mechanism to automatically adjust tension as needed, enhancing its functionality 4.

Benefits of Using the Cummins 5333482 Belt Tensioner

Using the Cummins 5333482 Belt Tensioner offers several benefits. It contributes to improved engine performance by ensuring that belts operate at the optimal tension. This reduces wear on the belts, leading to longer belt life and fewer replacements. Additionally, the tensioner enhances the reliability of the engine system by maintaining consistent belt tension, which is crucial for the efficient operation of engine-driven accessories 1.

Installation Process

Installing the Cummins 5333482 Belt Tensioner involves several steps to ensure proper fit and function. It is important to follow manufacturer guidelines for installation to avoid issues such as improper belt tension or damage to the tensioner. Key considerations include ensuring the engine is cool before beginning the installation, using the correct tools for the job, and verifying that the tensioner is securely mounted and properly aligned with the belt 2.

Troubleshooting Common Issues

Common issues with belt tensioners may include noise from the tensioner, belt slippage, or failure of the tensioner to maintain proper belt tension. Troubleshooting these issues involves inspecting the tensioner for signs of wear or damage, checking the belt for proper tension and condition, and ensuring that the tensioner is correctly installed and aligned. Solutions may range from adjusting the tensioner to replacing worn components 3.

Maintenance Tips

Regular maintenance of the Cummins 5333482 Belt Tensioner is important for its longevity and optimal performance. This includes periodic inspection of the tensioner and belts for signs of wear or damage, ensuring that the tensioner is properly lubricated if required, and following manufacturer recommendations for replacement intervals. Adhering to these maintenance practices helps to prevent unexpected failures and ensures the efficient operation of the engine system 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product offerings include engines for on-highway, off-highway, and power generation applications, as well as filtration and aftermarket parts. Cummins is renowned for its commitment to quality, performance, and customer satisfaction in the automotive industry.

Belt Tensioner Part 5333482 Compatibility with Cummins Engines

The Belt Tensioner part number 5333482, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the engine components.

ISC Series Engines

The ISC CM2150 and ISC8.3 CM2250 engines are part of the ISC series, which are known for their robust performance and reliability. The Belt Tensioner part 5333482 is compatible with these engines, ensuring that the serpentine belt maintains the correct tension, which is vital for the proper functioning of the engine’s ancillary systems.

ISL Series Engines

The ISL CM2150, ISL9 CM2150 SN, and ISL9 CM2250 engines are part of the ISL series, which are designed for heavy-duty applications. The Belt Tensioner part 5333482 is also compatible with these engines, providing the necessary tension to the serpentine belt to ensure that the alternator, water pump, and other belt-driven components operate efficiently.

QSK Series Engine

The QSK95 CM2350 K113 engine, part of the QSK series, is another engine that the Belt Tensioner part 5333482 is compatible with. This engine is known for its high power output and efficiency, and the belt tensioner plays a critical role in maintaining the performance of the engine’s belt-driven systems.

By ensuring that the Belt Tensioner part 5333482 is correctly installed and maintained, operators can help to extend the life of their engines and reduce the risk of belt-related failures.

Role of Part 5333482 Belt Tensioner in Engine Systems

The part 5333482 Belt Tensioner is an integral component in maintaining the efficiency and reliability of engine systems by ensuring proper tension on the drive belt. This, in turn, facilitates the seamless operation of various engine-driven accessories.

Interaction with the Drive System

In the drive system, the Belt Tensioner works in conjunction with the drive belt to transfer power from the engine to multiple components. By maintaining the correct tension, it prevents slippage and ensures consistent power transmission. This is particularly important for the smooth rotation of pulleys connected to the drive belt, which are essential for the operation of engine accessories.

Contribution to Alternator Functionality

The alternator is a key component that relies on the drive belt for its operation. The Belt Tensioner ensures that the drive belt remains taut as it wraps around the alternator pulley. This consistent tension is vital for the alternator to spin at the correct speed, which is necessary for efficient charging of the battery and powering of the electrical systems within the vehicle. Without proper tension, the alternator may not function optimally, leading to potential electrical issues and reduced battery life.

Conclusion

The Cummins 5333482 Belt Tensioner plays a significant role in the coordination and efficiency of the drive and alternator systems within an engine, ensuring that these components operate harmoniously and effectively. Proper maintenance and installation of this Cummins part are essential for the longevity and optimal performance of the engine system.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ ↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.