This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

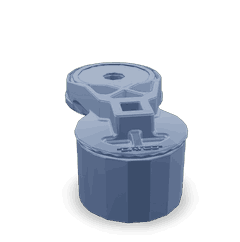

The Cummins 5333497 Belt Tensioner is a component designed to ensure the proper functioning of drive belts in commercial trucks. Its role is to maintain the correct tension on these belts, which is vital for the efficient operation of various engine-driven accessories such as the alternator, water pump, and air conditioning compressor. This part contributes to the overall reliability and performance of the truck’s engine system 2.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep drive belts at the proper tension. It typically consists of a spring-loaded arm with a pulley that applies consistent pressure to the belt. Proper belt tension is important for several reasons: it ensures efficient power transmission from the engine to the accessories, reduces wear and tear on the belts, and helps prevent belt slippage, which can lead to decreased performance and potential damage to the engine components 1.

Purpose of the 5333497 Belt Tensioner

The Cummins 5333497 Belt Tensioner is specifically designed to maintain the correct tension on the drive belts of a truck’s engine. By doing so, it plays a role in ensuring that the belts operate within their optimal range, which contributes to the smooth and efficient functioning of the engine-driven accessories. This tensioner helps in prolonging the life of the belts and enhances the overall performance of the engine system 2.

Key Features

The Cummins 5333497 Belt Tensioner is characterized by several key features that enhance its performance. It is constructed using durable materials that can withstand the harsh conditions of commercial truck operations. The design includes a spring-loaded mechanism that automatically adjusts to maintain consistent belt tension. Additionally, it is engineered to integrate seamlessly with the truck’s engine system, ensuring compatibility and ease of installation 2.

Benefits of Using the 5333497 Belt Tensioner

Utilizing the Cummins 5333497 Belt Tensioner offers several advantages. It contributes to improved belt life by maintaining optimal tension, which reduces the likelihood of belt failure. Enhanced engine performance is another benefit, as properly tensioned belts ensure efficient operation of engine accessories. Furthermore, the use of this tensioner can lead to reduced maintenance requirements, as it helps prevent issues related to belt wear and slippage 2.

Installation Process

Installing the Cummins 5333497 Belt Tensioner involves several steps. First, the old tensioner, if present, should be removed. Then, the new tensioner should be positioned in the engine compartment, aligning it with the mounting points. Using the appropriate tools, secure the tensioner in place. Finally, adjust the tensioner to ensure the belts are at the correct tension, following the manufacturer’s guidelines for proper setup 2.

Troubleshooting Common Issues

Common problems associated with belt tensioners include belt slippage, unusual noises, and visible wear on the tensioner or belts. These issues can often be traced back to improper installation, wear and tear, or incorrect tension settings. Solutions may involve readjusting the tensioner, replacing worn belts, or, in some cases, replacing the tensioner itself if it is damaged 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5333497 Belt Tensioner, regular maintenance is recommended. This includes periodic inspections to check for signs of wear on the tensioner and belts. It is also important to ensure that the tensioner is properly adjusted and that the belts are not showing signs of excessive wear or slippage. If any issues are detected, they should be addressed promptly to prevent further damage 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. The company’s product range includes a variety of engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications 2.

Belt Tensioner Part 5333497 Compatibility with Cummins Engines

The Belt Tensioner part number 5333497, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s accessory drive belt, ensuring efficient operation and longevity of the belt and associated components 2.

K38 Series Engines

The K38 series engines, known for their robust performance and reliability, are well-suited for the Belt Tensioner part 5333497. This part ensures that the accessory drive belt maintains the correct tension, which is essential for the proper functioning of components such as the alternator, water pump, and air conditioning compressor. The design of the K38 engines allows for seamless integration of the Belt Tensioner, providing a stable and efficient power transfer system 2.

K50 Series Engines

Similarly, the K50 series engines benefit from the use of the Belt Tensioner part 5333497. These engines, which are engineered for high performance and durability, require a reliable tensioning system to ensure that the accessory drive belt operates within optimal parameters. The Belt Tensioner part 5333497 is engineered to fit precisely within the design specifications of the K50 engines, ensuring that the belt remains taut and operational, thereby enhancing the overall efficiency and reliability of the engine 2.

Grouping of Engines

Both the K38 and K50 series engines share common design principles that make them compatible with the Belt Tensioner part 5333497. The part’s design is such that it can be easily installed and maintained across these engine series, providing a standardized solution for maintaining belt tension. This compatibility allows for easier maintenance and repair processes, as the same part can be used across multiple engine models, reducing the need for specialized parts and tools 2.

Role of Part 5333497 Belt Tensioner in Engine Systems

The part 5333497 Belt Tensioner is integral to maintaining the proper function and efficiency of various engine components. When integrated into engine systems, this component ensures that the belts driving essential parts remain taut, thereby optimizing performance and longevity 2.

Interaction with Mounting

The mounting system is the foundation upon which the Belt Tensioner is securely fastened. Proper mounting of the Belt Tensioner is essential for its stability and effectiveness. The tensioner must be firmly attached to the engine block or designated mounting points to withstand the dynamic forces exerted during engine operation. This secure attachment allows the tensioner to apply consistent pressure on the belt, preventing slippage and ensuring smooth operation of connected components 2.

Coordination with Alternator

The alternator is a key component that relies on the Belt Tensioner for optimal function. The Belt Tensioner maintains the necessary tension on the drive belt that connects to the alternator. This tension is vital for the alternator to spin at the correct speed, ensuring efficient charging of the battery and powering of the electrical systems. Without adequate tension, the belt may slip, leading to inefficient alternator performance, reduced charging efficiency, and potential electrical system failures. The Belt Tensioner, therefore, plays a significant role in maintaining the alternator’s operational integrity and the overall electrical health of the engine system 2.

Conclusion

The Cummins 5333497 Belt Tensioner is a critical component in the maintenance and efficiency of commercial truck engine systems. Its proper installation, maintenance, and function are essential for the optimal performance of engine-driven accessories and the overall reliability of the engine system. Regular maintenance and prompt addressing of any issues ensure the longevity and effectiveness of this part 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.