5581825

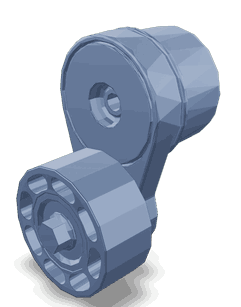

Tensioner Belt

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5581825 Tensioner Belt is a component designed for use in commercial trucks. Its purpose is to maintain the proper tension of the belts within the engine system, ensuring efficient operation and longevity of the engine components. This tensioner belt is integral to the smooth functioning of the truck’s engine, contributing to overall performance and reliability.

Basic Concepts of Tensioner Belts

A tensioner belt operates within a truck’s engine system to keep the belts at the correct tension. This is achieved through a mechanism that applies consistent pressure to the belt, allowing it to grip the pulleys effectively without slipping. Proper belt tension is vital for the efficient transfer of power from the engine to various components such as the alternator, water pump, and air conditioning compressor. It ensures that these components receive the necessary power to function correctly, thereby maintaining the engine’s overall efficiency 1.

Role of the 5581825 Tensioner Belt in Truck Operation

The Cummins 5581825 Tensioner Belt plays a specific role in the operation of a truck by interacting with other engine components to maintain optimal belt tension. This tensioner belt works in conjunction with the engine’s pulleys and belts to ensure that power is transmitted efficiently throughout the engine system. By maintaining the correct tension, it contributes to the engine’s efficiency and performance, reducing the risk of belt slippage or failure. This, in turn, helps in preventing unnecessary wear on the belts and pulleys, ensuring the engine operates smoothly and reliably 2.

Key Features

The Cummins 5581825 Tensioner Belt is designed with several key features that enhance its performance and durability. These include a robust construction that can withstand the high stresses and temperatures within an engine environment. The belt is made from high-quality materials that offer excellent resistance to wear and tear, ensuring long-lasting performance. Additionally, its design incorporates elements that allow for easy installation and adjustment, making it a practical choice for maintenance and repair 3.

Benefits

The Cummins 5581825 Tensioner Belt provides several benefits that contribute to improved engine performance and reliability. By maintaining the correct belt tension, it ensures that power is efficiently transferred throughout the engine system, leading to enhanced performance. This also reduces wear on the belts and pulleys, extending their lifespan and reducing the need for frequent replacements. Furthermore, the reliable operation of the tensioner belt enhances the overall reliability of the engine, providing peace of mind to truck operators.

Troubleshooting and Maintenance

Common issues that may arise with tensioner belts include belt slippage, excessive wear, and noise during operation. To troubleshoot these problems, it is important to inspect the belt for signs of wear or damage and ensure that it is properly tensioned. Regular maintenance practices, such as checking the tension and condition of the belt during routine inspections, can help prevent issues and ensure the longevity and optimal performance of the Cummins 5581825 Tensioner Belt. Additionally, following the manufacturer’s recommendations for replacement intervals can help maintain engine efficiency and reliability.

Compatibility with Cummins Engines

The Cummins part 5581825, a Tensioner Belt, is designed to be compatible with a range of engines, ensuring optimal performance and longevity. This tensioner belt is engineered to maintain the correct tension on the engine’s serpentine belt, which is crucial for the efficient operation of various engine components such as the alternator, water pump, and air conditioning compressor.

For the X12 CM2350 engine, the 5581825 tensioner belt is specifically tailored to fit the unique configuration and requirements of this engine model. Its precision design ensures that it can withstand the operational stresses and demands of the X12 CM2350, providing reliable tension and reducing the risk of belt slippage or failure.

Similarly, the X119B engine benefits from the use of the 5581825 tensioner belt. This part is crafted to align perfectly with the X119B’s design, ensuring that the belt maintains the necessary tension across the engine’s pulleys. This compatibility is critical for maintaining the balance and efficiency of the engine’s ancillary systems.

Role in Alternator Drive System

In the alternator drive system, the Tensioner Belt plays a significant role. It keeps the belt that drives the alternator pulley under the correct tension. This ensures that the alternator receives consistent rotational force from the engine, allowing it to generate a stable electrical output. Without adequate tension, the belt might slip, leading to inefficient power generation and potential damage to the alternator.

Additionally, the Tensioner Belt helps in reducing wear and tear on the alternator pulley and the belt itself. By maintaining consistent tension, it prevents the belt from becoming overly loose or tight, which can cause premature wear or failure. This consistent tension also contributes to the smooth operation of the alternator, minimizing vibrations and noise.

Furthermore, the Tensioner Belt assists in accommodating the thermal expansion of the belt. As the engine operates, components heat up and expand. The tensioner allows for this expansion by adjusting the tension dynamically, ensuring that the belt remains effective throughout the engine’s operating range.

Conclusion

The Cummins 5581825 Tensioner Belt is a critical component for maintaining the proper operation of various engine systems by ensuring the belts remain taut and correctly aligned. Its role in the alternator drive system, compatibility with Cummins engines, and the benefits it provides in terms of performance and reliability make it an essential part for commercial truck engines.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.