This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

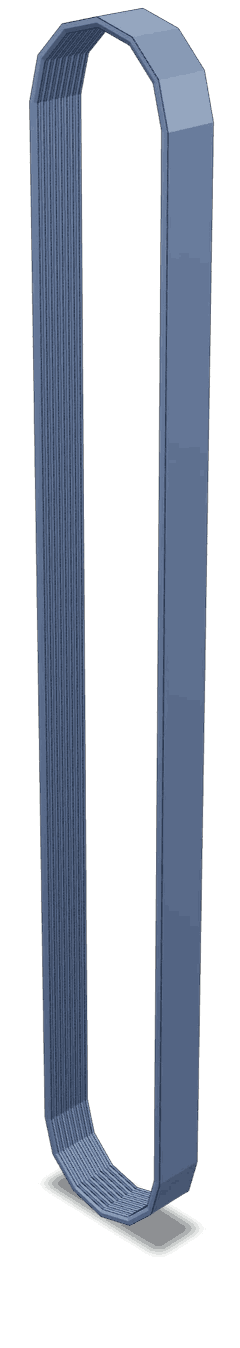

The Cummins 5690160 V Ribbed Belt is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of power from the engine to various accessories. Understanding its function and importance can help in maintaining the efficiency and reliability of truck operations.

Basic Concepts of V Ribbed Belts

V Ribbed Belts are a type of drive belt characterized by their trapezoidal cross-section, which allows them to engage with corresponding grooves on pulleys. This design enhances grip and reduces slippage, making them suitable for automotive applications where reliable power transmission is required 1. V Ribbed Belts are constructed from a combination of materials, typically including rubber and fabric reinforcements, which contribute to their durability and performance under varying conditions.

Purpose of the 5690160 V Ribbed Belt

This Cummins part plays a role in the operation of a truck by driving various engine accessories such as the alternator, water pump, and air conditioning compressor. Its function is to transfer rotational force from the engine crankshaft to these components, ensuring they operate efficiently and contribute to the overall performance of the vehicle.

Key Features

The Cummins 5690160 V Ribbed Belt features a specific material composition and rib design that enhance its performance and durability. The belt is constructed from high-quality materials that provide resistance to wear and environmental factors. Its rib design is tailored to match the pulleys in the truck’s engine system, ensuring optimal power transmission and reduced risk of slippage.

Benefits

Using the Cummins 5690160 V Ribbed Belt offers several benefits. It contributes to improved efficiency in power transmission, which can lead to better overall engine performance. The design and materials used in the belt help reduce maintenance requirements by enhancing its durability. Additionally, the reliable performance of the belt supports the continued operation of essential engine accessories, contributing to the truck’s reliability.

Installation Considerations

When installing the Cummins 5690160 V Ribbed Belt, it is important to follow guidelines and best practices to ensure optimal performance. Proper tensioning and alignment of the belt on the pulleys are critical to prevent slippage and ensure efficient power transmission. Careful attention to these details during installation can help maintain the belt’s performance and longevity.

Troubleshooting Common Issues

Common issues that may arise with V Ribbed Belts include slippage, wear, and noise. Slippage can occur if the belt is not properly tensioned or if it has become worn. Wear may be indicated by cracks or fraying on the belt’s surface. Noise can be a sign of misalignment or excessive wear. Troubleshooting these issues often involves inspecting the belt and pulleys, adjusting tension, and replacing the belt if necessary 2.

Maintenance Tips

To prolong the lifespan of the Cummins 5690160 V Ribbed Belt and ensure continued reliable performance, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring proper tension and alignment, and replacing the belt according to manufacturer recommendations or when signs of significant wear are observed.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its range of diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins offers a variety of products designed to meet the demands of commercial and industrial applications. The company’s reputation is built on its ability to deliver reliable, high-performance solutions for its customers.

Conclusion

The Cummins 5690160 V Ribbed Belt is a critical component in the operation of commercial trucks, facilitating efficient power transmission to essential engine accessories. Its design and material composition contribute to its durability and performance, offering benefits such as improved engine efficiency and reduced maintenance requirements. Proper installation, regular maintenance, and timely troubleshooting of common issues are essential to ensure the reliable operation of this part and the overall performance of the vehicle.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.