This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

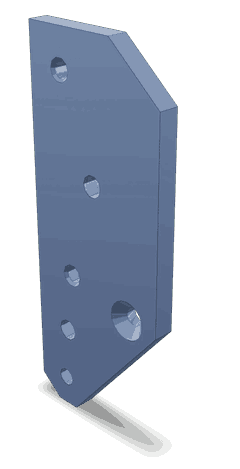

The Belt Tensioner Bracket 3286296 is a component designed by Cummins to ensure the proper functioning of the belt tensioner system in commercial trucks. This part is integral to maintaining the correct tension on the serpentine belt, which drives various engine accessories such as the alternator, water pump, and air conditioning compressor. Its role is significant in the operation of commercial trucks, contributing to the efficiency and reliability of the engine system 1.

Basic Concepts of Belt Tensioner Brackets

A Belt Tensioner Bracket serves as a mounting point for the belt tensioner, which is responsible for maintaining the appropriate tension on the serpentine belt. This tension is crucial for the efficient transfer of power from the engine to the driven accessories. By ensuring the belt remains properly tensioned, the bracket helps prevent slippage, reduces wear on the belt and pulleys, and contributes to the overall performance and longevity of the truck’s engine system 2.

Purpose of the 3286296 Belt Tensioner Bracket

The 3286296 Belt Tensioner Bracket plays a role in the operation of a truck by securely mounting the belt tensioner. It interacts with the serpentine belt and pulleys to maintain consistent tension, which is vital for the efficient operation of engine accessories. This bracket ensures that the belt tensioner can effectively adjust to changes in belt length due to temperature variations and wear, thereby supporting the smooth and reliable operation of the truck.

Key Features

The 3286296 Belt Tensioner Bracket is designed with several key features that enhance its performance. It is constructed from durable materials to withstand the rigors of commercial truck operation. The bracket is engineered to provide a stable mounting point for the belt tensioner, ensuring precise alignment and tension maintenance. Additionally, its design allows for easy installation and adjustment, facilitating maintenance and replacement when necessary.

Benefits

The 3286296 Belt Tensioner Bracket offers several benefits that contribute to the efficient operation of commercial trucks. By maintaining optimal belt tension, it helps reduce wear on the serpentine belt and pulleys, leading to longer component life. Improved belt tension also enhances engine efficiency, as accessories receive consistent power transfer. Furthermore, the bracket’s durable construction and precise design contribute to the overall reliability and performance of the truck’s engine system.

Installation Process

Installing the 3286296 Belt Tensioner Bracket requires careful attention to ensure proper fitting and function. Begin by locating the mounting points on the engine block or frame. Use the appropriate tools to secure the bracket in place, ensuring it is aligned correctly with the belt tensioner and pulleys. Tighten the mounting bolts to the specified torque settings to ensure a secure fit. Finally, verify that the belt tensioner is properly aligned and that the serpentine belt is correctly tensioned.

Troubleshooting Common Issues

Common issues associated with Belt Tensioner Brackets include noise, vibration, and belt slippage. These problems can often be traced to improper installation, wear on the bracket or tensioner, or incorrect belt tension. To address these issues, first, ensure the bracket is securely mounted and aligned. Inspect the belt tensioner for signs of wear or damage, and adjust the belt tension as necessary. If noise or vibration persists, further investigation may be required to identify and resolve the underlying cause.

Maintenance Tips

Regular maintenance of the 3286296 Belt Tensioner Bracket is important to ensure its longevity and optimal performance. Inspect the bracket and tensioner during routine engine checks for signs of wear, corrosion, or damage. Pay attention to the condition of the serpentine belt, ensuring it is properly tensioned and free from cracks or glazing. Address any issues promptly to prevent further damage and ensure the efficient operation of the truck’s engine system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of commercial applications. Cummins continues to lead the industry with advanced technologies and solutions that enhance performance, efficiency, and sustainability.

Compatibility with Cummins Engines

The Belt Tensioner Bracket 3286296, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s belts, ensuring efficient operation and longevity of the engine components.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ range of medium-duty diesel engines. The Belt Tensioner Bracket 3286296 is compatible with these engines, providing a secure mounting point for the belt tensioner. This ensures that the belts remain properly tensioned, which is essential for the smooth operation of the engine’s ancillary systems such as the alternator, water pump, and air conditioning compressor.

B5.9 G and ISB5.9 G CM2180 Engines

The B5.9 G and ISB5.9 G CM2180 engines are more advanced models within Cummins’ lineup, often used in heavy-duty applications. The Belt Tensioner Bracket 3286296 is also compatible with these engines. Its design allows for precise adjustment and secure fastening of the belt tensioner, which is critical in these high-performance engines to maintain optimal belt tension under varying load conditions.

Grouping of Compatible Engines

The Belt Tensioner Bracket 3286296 is engineered to fit seamlessly with the following Cummins engines:

- 4B3.9

- 6B5.9

- B5.9 G

- ISB5.9 G CM2180

This compatibility ensures that the bracket can be used across different engine models, providing a standardized solution for maintaining belt tension in various Cummins engine applications.

Conclusion

The Belt Tensioner Bracket 3286296 is an integral component in the orchestration of the engine’s accessory drive system. Its primary function is to maintain the correct tension on the drive belt, which is essential for the efficient operation of various engine-driven accessories. When integrated with the alternator drive system, the Belt Tensioner Bracket ensures that the drive belt remains taut, facilitating the smooth transfer of rotational force from the engine’s crankshaft to the alternator. This tension is vital for the alternator to generate electrical power consistently, which is then used to charge the battery and power the vehicle’s electrical systems.

The bracket’s design allows for automatic adjustment of belt tension, accommodating the natural stretch and wear that occurs over time. This self-adjusting feature is particularly important in maintaining optimal performance of the alternator, as improper belt tension can lead to inefficient power generation, increased wear on the belt, and potential failure of the alternator.

Furthermore, the Belt Tensioner Bracket plays a role in reducing noise and vibration within the engine compartment. By keeping the belt properly tensioned, it minimizes slippage and the associated noise, contributing to a quieter and more comfortable driving experience.

In summary, the Belt Tensioner Bracket is a key element in the engine’s accessory drive system, working in concert with components like the alternator to ensure reliable and efficient operation of the vehicle’s electrical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.