This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

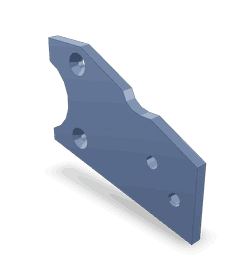

The Belt Tensioner Bracket, identified by part number 3287542, is a component manufactured by Cummins. This Cummins part plays a significant role in the operational efficiency of heavy-duty trucks. It is designed to support the belt tensioner, which is essential for maintaining the proper tension of the belts within the engine system. Cummins, a well-established name in the automotive industry, ensures that this component meets high standards of quality and performance 1.

Function and Operation

The Belt Tensioner Bracket operates as a foundational element within the truck’s engine system. Its primary role is to securely hold the belt tensioner in place, allowing it to adjust the tension of the belts that drive various engine components such as the alternator, water pump, and air conditioning compressor. By maintaining optimal belt tension, the bracket helps ensure that these components operate efficiently and reliably. The tensioner automatically adjusts to compensate for belt wear and thermal expansion, which is facilitated by the stable mounting provided by the bracket 2.

Key Features

The design of the Belt Tensioner Bracket by Cummins incorporates several features that enhance its performance and durability. Constructed from high-strength materials, the bracket is resistant to corrosion and capable of withstanding the high temperatures and vibrations typical in heavy-duty truck environments. Its design allows for easy installation and adjustment, ensuring that the belt tensioner can be properly aligned and secured. Additionally, the bracket’s surface may include features such as grooves or ridges to improve its grip on the tensioner, further enhancing stability and performance 3.

Benefits

The Belt Tensioner Bracket offers several advantages that contribute to the overall efficiency and reliability of the truck’s engine system. By ensuring that belts are properly tensioned, it helps reduce slippage, which can lead to improved engine efficiency and reduced fuel consumption. Proper belt tension also minimizes wear on the belts themselves, extending their lifespan and reducing the frequency of replacements. Furthermore, the stable mounting provided by the bracket enhances the overall reliability of the engine system, contributing to smoother operation and potentially reducing maintenance costs.

Installation and Maintenance

Proper installation of the Belt Tensioner Bracket is crucial for its effective operation. It should be securely fastened to the engine block using the appropriate tools and following the manufacturer’s guidelines. Regular inspection of the bracket and the belt tensioner is recommended to ensure that they remain in good condition. Maintenance tasks may include checking for signs of wear or corrosion, ensuring that the tensioner moves freely, and verifying that the belts are properly tensioned. Any issues identified during maintenance should be addressed promptly to prevent more significant problems.

Troubleshooting Common Issues

Common issues associated with Belt Tensioner Brackets may include misalignment of the tensioner, wear on the bracket itself, or problems with the tensioner’s movement. Misalignment can often be corrected by re-securing the bracket or adjusting the tensioner’s position. Wear on the bracket may require replacement, especially if it affects the tensioner’s ability to function correctly. If the tensioner does not move freely, it may be necessary to lubricate its moving parts or, in some cases, replace the tensioner itself. Regular maintenance and inspections can help identify these issues early, allowing for timely corrective action.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a history spanning several decades, Cummins has established a reputation for innovation, reliability, and excellence. The company’s dedication to quality is evident in its rigorous testing and quality control processes, ensuring that each component, including the Belt Tensioner Bracket, meets the highest standards of performance and durability. Cummins’ expertise and reputation make it a trusted choice for automotive components, providing peace of mind to truck operators and maintenance professionals alike.

Belt Tensioner Bracket 3287542 Compatibility with Cummins Engines

The Belt Tensioner Bracket 3287542, manufactured by Cummins, is a critical component in the engine’s belt drive system. This part ensures that the engine’s serpentine or V-belt maintains proper tension, which is essential for the efficient operation of the engine’s ancillary components such as the alternator, water pump, and air conditioning compressor.

Compatibility with Specific Engine Models

-

4B3.9 Engine Series

- The Belt Tensioner Bracket 3287542 is specifically designed to fit the 4B3.9 engine series. This engine model is known for its reliability and performance in various applications. The bracket’s design ensures a secure fit, maintaining the correct belt tension and preventing slippage or excessive wear.

-

6B5.9 Engine Series

- Similarly, the 6B5.9 engine series benefits from the use of the Belt Tensioner Bracket 3287542. This engine is recognized for its robust construction and efficiency. The bracket’s precise engineering allows it to integrate seamlessly with the engine’s design, ensuring optimal performance and longevity of the belt system.

Grouping of Engine Models

When considering the compatibility of the Belt Tensioner Bracket 3287542, it is important to note that both the 4B3.9 and 6B5.9 engine series share common design principles in their belt drive systems. This commonality allows the same part to be used across these engine models, simplifying maintenance and repair processes.

By ensuring that the Belt Tensioner Bracket 3287542 is correctly installed, engine operators can maintain the integrity of their belt drive systems, leading to improved engine performance and reduced downtime.

Role of Part 3287542 Belt Tensioner Bracket in Engine Systems

The Belt Tensioner Bracket, identified by part number 3287542, is integral to the efficient operation of several engine components. It serves as a mounting point for the belt tensioner, which is responsible for maintaining the correct tension on the drive belt. This ensures optimal performance and longevity of the components driven by the belt.

In systems featuring an alternator drive, the Belt Tensioner Bracket plays a significant role. It secures the tensioner in place, allowing it to apply the necessary force to keep the drive belt taut. This is essential for the alternator to function correctly, as the belt drives the alternator pulley, generating electrical power for the vehicle’s electrical systems.

Additionally, the Belt Tensioner Bracket contributes to the stability and alignment of the belt within the engine compartment. Proper alignment prevents slippage and reduces wear on both the belt and the pulleys it engages with. This, in turn, enhances the overall efficiency and reliability of the engine system.

Furthermore, the bracket’s design allows for easy adjustment of the belt tension, facilitating maintenance and replacement procedures. This feature is particularly beneficial during routine inspections or when replacing the drive belt, ensuring that the tensioner can be quickly realigned to specifications.

Conclusion

In summary, the Belt Tensioner Bracket (part 3287542) is a key component in maintaining the integrity and performance of the drive belt system, directly influencing the operation of connected components such as the alternator. Its proper installation and maintenance are crucial for ensuring the efficient and reliable operation of heavy-duty truck engines.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.