This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

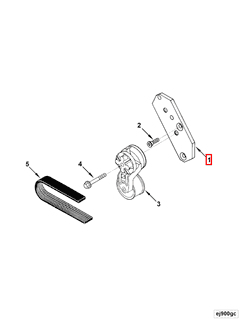

Introduction to Belt Tensioner Brackets

A belt tensioner bracket is a vital component in the engine system of commercial trucks. It ensures the proper tension of the engine’s serpentine belt, which drives essential accessories such as the alternator, water pump, and air conditioning compressor. For engineers and mechanics, understanding the function and importance of the belt tensioner bracket is crucial for maintaining engine efficiency and reliability 1.

The Role of the 3904548 Belt Tensioner Bracket

The 3904548 belt tensioner bracket, manufactured by Cummins, is designed to keep the serpentine belt taut and properly aligned. This component prevents slippage, which can lead to reduced efficiency and potential damage to the engine’s components. By maintaining the correct tension, the belt tensioner bracket ensures smooth and reliable engine operation 2.

How the 3904548 Belt Tensioner Bracket Works

The 3904548 belt tensioner bracket operates in conjunction with a tensioner pulley or idler pulley. When the belt is installed, the tensioner bracket holds the tensioner pulley in place, applying the necessary force to keep the belt tight. As the engine runs, the belt tensioner bracket absorbs vibrations and movements, ensuring that the belt remains in optimal condition 3.

Importance of the 3904548 Belt Tensioner Bracket in Truck Operations

For commercial trucks, the reliability of the belt tensioner bracket is paramount. A malfunctioning belt tensioner bracket can lead to belt failure, causing a cascade of issues such as loss of power steering, alternator failure, and engine overheating. Regular maintenance and timely replacement of the belt tensioner bracket are essential to prevent these problems and ensure the longevity of the engine 4.

Troubleshooting the 3904548 Belt Tensioner Bracket

Mechanics and fleet operators should be aware of the signs of a failing belt tensioner bracket. Common symptoms include squealing or chirping noises from the engine, visible wear or cracks on the bracket, and a loose or slipping belt. If any of these signs are present, it is crucial to inspect and, if necessary, replace the belt tensioner bracket promptly 5.

Maintenance Tips for the 3904548 Belt Tensioner Bracket

Regular maintenance of the belt tensioner bracket can help prevent unexpected failures. Mechanics should inspect the bracket during routine service intervals, checking for signs of wear, corrosion, or damage. Lubricating the pivot points and ensuring that the bracket is securely mounted can also help maintain its functionality. Additionally, using high-quality replacement parts, such as the Cummins 3904548 belt tensioner bracket, can ensure optimal performance and longevity 6.

Belt Tensioner Bracket 3904548 Compatibility with Cummins Engines

The Belt Tensioner Bracket 3904548, manufactured by Cummins, is a critical component designed to ensure the proper tensioning of belts in various engine systems. This part is engineered to fit seamlessly with several Cummins engine models, providing a reliable solution for maintaining belt integrity and performance.

Group 1: 4B3.9, 6B5.9, B5.9 G, B5.9 GAS PLUS CM556, G5.9

The Belt Tensioner Bracket 3904548 is compatible with the following engines:

- 4B3.9

- 6B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- G5.9

These engines, while differing in specifications and applications, share a commonality in the design of their belt tensioning systems. The bracket’s robust construction and precise fit ensure that it can effectively manage belt tension across these models, contributing to the overall efficiency and longevity of the engine.

Group 2: ISB5.9G CM2180

The Belt Tensioner Bracket 3904548 also fits the ISB5.9G CM2180 engine. This engine, known for its high performance and reliability, benefits from the bracket’s ability to maintain optimal belt tension, thereby enhancing engine performance and reducing the risk of belt-related failures.

By ensuring a secure and consistent fit across these engines, the Belt Tensioner Bracket 3904548 plays a crucial role in the maintenance and operation of Cummins engine systems.

Role of Part 3904548 Belt Tensioner Bracket in Engine Systems

The Belt Tensioner Bracket, identified by part number 3904548, is integral to the efficient operation of several key components within an engine system. This bracket is designed to support the belt tensioner, which maintains the proper tension on the drive belt. The drive belt, in turn, is responsible for transferring power from the engine to various auxiliary components.

Interaction with the Alternator

One of the primary components influenced by the Belt Tensioner Bracket is the alternator. The alternator relies on consistent and adequate belt tension to function correctly. The bracket ensures that the tensioner applies the necessary force to keep the belt taut, allowing the alternator to generate electricity efficiently. Without proper tension, the alternator may not spin at the required speed, leading to insufficient power generation and potential battery issues.

Drive System Efficiency

The Belt Tensioner Bracket also plays a significant role in the overall drive system efficiency. By maintaining optimal belt tension, the bracket helps reduce slippage and wear on the belt. This ensures that power transfer to other components, such as the water pump and power steering pump, remains consistent and reliable. Efficient belt tension contributes to the longevity of the belt and the smooth operation of the drive system.

Integration with Engine Components

In addition to the alternator and drive system, the Belt Tensioner Bracket indirectly supports other engine components that rely on the drive belt. These may include the air conditioning compressor and the fuel pump, depending on the specific engine configuration. By ensuring that the belt remains properly tensioned, the bracket helps these components operate within their designed parameters, enhancing the overall performance and reliability of the engine system.

Conclusion

Understanding the intricacies of the belt tensioner bracket and its role in engine operation is essential for maintaining the efficiency and reliability of commercial trucks. By staying informed about the function, maintenance, and troubleshooting of components like the 3904548 belt tensioner bracket, engineers, mechanics, and fleet operators can ensure that their vehicles remain in top condition, minimizing downtime and maximizing performance.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩ -

Internal Combustion Engines, Kazimierz Lejda and Pawel Wos, InTech, 2012

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

↩ -

X15 CM2350 X132C, Bulletin Number 5504570, Owners Manual

↩ -

Cummins, a leading manufacturer of engines, engine components, and related technologies, is renowned for its quality and reliability in the commercial truck industry.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.