This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

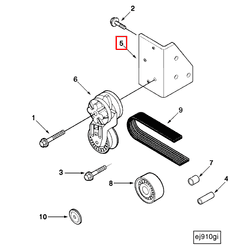

The Belt Tensioner Bracket 3914611, manufactured by Cummins, is a critical component in the efficient operation of commercial trucks. This part ensures the proper functioning of engine-driven accessories by maintaining optimal belt tension 1.

Basic Concepts

Belt tensioner brackets are essential for maintaining the correct tension on drive belts, which are vital for the operation of various engine accessories such as alternators, water pumps, and power steering pumps 2. Proper belt tension ensures efficient operation and prevents slippage, which can lead to reduced efficiency and potential damage to the accessories.

Purpose and Role

The Belt Tensioner Bracket 3914611 is engineered to maintain optimal belt tension in commercial trucks. It supports the tensioner pulley, applying the necessary force to keep the belt taut. This ensures consistent power transmission to accessories, which is crucial for the reliable operation of the truck’s engine system 3.

Key Features

This Cummins part is constructed from high-quality materials to ensure durability and performance. Its design includes precise engineering to accommodate the tensioner pulley and provide stable support. The bracket is crafted to withstand the rigors of commercial truck operations, including vibrations and varying temperatures.

Benefits

Using the Belt Tensioner Bracket 3914611 offers several advantages. It contributes to improved belt longevity by maintaining consistent tension, which reduces wear and tear on belts. This leads to reduced maintenance requirements and lower downtime for trucks. Additionally, proper belt tension enhances overall engine performance by ensuring that accessories operate efficiently.

Troubleshooting and Maintenance

Common issues with belt tensioner brackets may include wear on the bracket itself or misalignment of the tensioner pulley. Regular inspection and maintenance are recommended to identify any signs of wear or damage. Ensuring that the bracket is properly aligned and that the tensioner pulley moves freely can help maintain optimal performance. Lubricating moving parts as per the manufacturer’s recommendations can also extend the lifespan of the bracket and associated components.

Installation Considerations

When installing the Belt Tensioner Bracket 3914611, it is important to ensure proper alignment with the engine’s accessory drive system. Following torque specifications provided by Cummins is crucial to secure the bracket without over-tightening, which could lead to damage. Compatibility with other components should also be verified to ensure a seamless integration into the truck’s engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation within the commercial trucking industry for producing reliable and high-performance engine components. Their product offerings include engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial applications 4.

Conclusion

The Belt Tensioner Bracket 3914611 is a vital component in the efficient operation of commercial trucks. By maintaining optimal belt tension, it ensures the reliable operation of engine-driven accessories, contributing to overall engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5677218.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.