This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

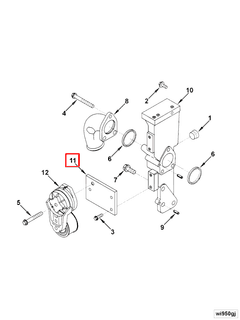

The Belt Tensioner Bracket 3924012, designed by Cummins, is a critical component for the efficient operation of commercial trucks. This bracket ensures that the belts driving various engine accessories maintain the correct tension, which is essential for the reliable and efficient operation of components such as the alternator, water pump, and air conditioning compressor.

Basic Concepts

Belt tensioner brackets are designed to maintain proper belt tension within an engine system. They automatically adjust the tension on the belts as they wear or stretch over time, ensuring that the belts remain taut enough to drive accessories effectively without slipping. This is achieved by applying consistent pressure to the belt, compensating for any changes in tension due to wear, temperature variations, or other factors 1.

Purpose and Function

The Belt Tensioner Bracket 3924012 ensures optimal belt tension, which is crucial for the efficient operation of engine components such as the alternator, water pump, and air conditioning compressor. By maintaining proper belt tension, the bracket helps prevent slippage, reduces wear on both the belts and the accessories they drive, and contributes to the overall reliability and performance of the engine 2.

Key Features

This Cummins part is characterized by several key features that enhance its functionality and durability. These include robust construction, precise engineering for accurate belt tension, and compatibility with a range of Cummins engines. The design of the bracket also allows for easy installation and maintenance, making it a practical choice for fleet managers and technicians.

Benefits

Utilizing the Belt Tensioner Bracket 3924012 offers several benefits. It contributes to improved engine performance by ensuring that belts operate at optimal tension, which enhances the efficiency of driven accessories. This can lead to reduced wear on belts and accessories, extending their service life. Additionally, the reliable operation of the tensioner bracket enhances the overall reliability of the engine, potentially reducing downtime and maintenance costs for fleet operators 3.

Installation and Maintenance

Proper installation and maintenance of the Belt Tensioner Bracket 3924012 are crucial for its effective operation. Installation should follow manufacturer guidelines to ensure the bracket is securely mounted and correctly aligned with the belts and accessories it supports. Regular maintenance, including inspection for signs of wear or damage, and adjustment or replacement as necessary, is recommended to ensure continued optimal performance. Technicians should refer to Cummins’ maintenance schedules and procedures for specific guidelines.

Troubleshooting

Common issues with belt tensioner brackets may include belt slippage, unusual noises from the tensioner area, or visible wear on the bracket or belt. Troubleshooting these issues involves inspecting the bracket and belt for signs of wear, ensuring the bracket is correctly installed and aligned, and checking for proper belt tension. If the bracket is found to be damaged or worn, replacement may be necessary to restore optimal belt tension and prevent further issues.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various industries, from transportation to construction and beyond. Cummins’ commitment to excellence is reflected in its product offerings, which are engineered to deliver superior performance, efficiency, and durability.

Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 3924012 is designed to fit a variety of Cummins engines. This bracket plays a crucial role in maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and related components.

Compatible Engines

- 4B3.9

- 6B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB CM550

- ISB5.9G CM2180

Grouping of Compatible Engines

The engines listed above can be grouped based on their series and configurations:

- 4B3.9 and 6B5.9: These engines are part of the B series, known for their robust build and reliability in various applications.

- B5.9 G and B5.9 GAS PLUS CM556: These engines are part of the B5.9 series, which includes both diesel and gas-powered variants. The “GAS PLUS” designation indicates an enhanced gas engine model.

- ISB CM550 and ISB5.9G CM2180: These engines belong to the ISB series, which is widely recognized for its versatility and performance across different industries. The “CM” prefix denotes a common rail diesel engine, while the “G” suffix indicates a gas engine variant.

Each of these engines, despite their differences, shares a common requirement for the Belt Tensioner Bracket 3924012 to ensure the serpentine belt is correctly tensioned, which is vital for the proper functioning of the engine’s ancillary systems.

Role of Belt Tensioner Bracket in Engine Systems

The Belt Tensioner Bracket 3924012 is integral to the efficient operation of various engine components. It ensures the proper tension of the drive belt, which is essential for the transmission of power to multiple engine accessories.

Connection to the Water Inlet

The Belt Tensioner Bracket is strategically positioned to maintain the correct tension on the drive belt as it wraps around the water pump pulley. This ensures that the water pump operates efficiently, providing consistent coolant flow through the water inlet and throughout the engine cooling system. Proper tension prevents slippage, which could lead to inadequate cooling and potential engine overheating.

Interaction with the Pulley

The pulley system is a key component in the engine’s accessory drive system. The Belt Tensioner Bracket works in conjunction with the pulley to keep the drive belt taut. This is vital for the efficient transfer of power from the engine to the pulley, which in turn drives accessories such as the alternator, power steering pump, and air conditioning compressor. Consistent tension ensures these components receive the necessary power without belt slippage or excessive wear.

Support for the Water Pump Drive

The water pump drive relies on the drive belt to function correctly. The Belt Tensioner Bracket plays a significant role here by ensuring that the belt remains properly tensioned as it moves over the water pump pulley. This consistent tension is necessary for the water pump to maintain optimal performance, ensuring that coolant is circulated effectively through the engine. This helps in regulating engine temperature and preventing overheating, which is essential for the longevity and reliability of the engine.

Conclusion

The Belt Tensioner Bracket 3924012 by Cummins is a vital component for the efficient and reliable operation of commercial truck engines. By maintaining optimal belt tension, this part ensures the proper functioning of engine accessories, reduces wear and tear, and contributes to the overall performance and longevity of the engine. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.