This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

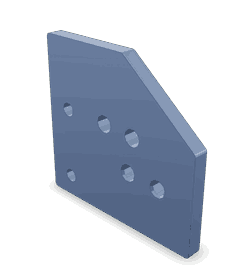

The Belt Tensioner Bracket 3925212, manufactured by Cummins, is a critical component in the commercial truck industry, ensuring the efficient operation of the engine system by maintaining the proper tension of the belts that drive various engine components 1.

Basic Concepts of Belt Tensioner Brackets

A Belt Tensioner Bracket is designed to hold and adjust the tension of the belts that connect and drive components such as the alternator, water pump, and air conditioning compressor. It automatically adjusts the tension on the belt as the engine runs, compensating for wear and changes in temperature that can affect belt length and tension 2.

Purpose of Belt Tensioner Bracket 3925212

This Cummins part plays a role in the operation of a truck by maintaining optimal belt tension for various engine components. This ensures that the belts run smoothly and efficiently, reducing the risk of slippage or breakage, which can lead to engine component failure or decreased performance 3.

Key Features

The Belt Tensioner Bracket 3925212 is constructed from high-strength materials to withstand the rigors of commercial truck operation. Its design includes precise engineering to ensure accurate belt tension adjustment, and it may incorporate features such as a built-in damper to reduce noise and vibration.

Benefits

The Belt Tensioner Bracket 3925212 offers several benefits, including improved engine efficiency through consistent belt tension, reduced wear on belts due to its automatic tensioning feature, and enhanced reliability of the truck’s engine system by preventing belt-related failures.

Installation Process

Installing this part requires careful attention to ensure proper function and safety. The process involves securing the bracket in its designated location on the engine, connecting it to the belt, and adjusting the tension according to the manufacturer’s specifications. Tools required may include a socket set and a tensioning tool, and safety precautions such as disconnecting the battery should be observed.

Troubleshooting Common Issues

Common problems associated with Belt Tensioner Brackets include noise, vibration, or belt slippage. These issues can often be traced to improper installation, wear and tear, or failure of the tensioner mechanism. Troubleshooting steps may involve inspecting the bracket and belt for signs of wear, ensuring the bracket is properly installed, and replacing the bracket or belt if necessary.

Maintenance Tips

Routine maintenance of the Belt Tensioner Bracket 3925212 is important for ensuring continued optimal performance. This includes regular inspection for signs of wear or damage, cleaning the bracket and surrounding areas to prevent buildup that could affect operation, and replacing the bracket when it shows significant wear or if belt slippage occurs despite adjustments.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation in the commercial truck industry. Its extensive product range and reputation for reliability make it a preferred choice for commercial vehicle operators worldwide.

Compatibility with Cummins Engines

The Belt Tensioner Bracket 3925212 is designed to work seamlessly with several Cummins engine models, ensuring optimal performance and longevity.

-

6C8.3 Engine Series

This part is specifically engineered to fit the 6C8.3 engine series. This engine is known for its robust design and reliability, often used in heavy-duty applications. The bracket’s precision fit ensures that the belt remains taut and operational, preventing slippage and maintaining the necessary tension for the engine’s auxiliary systems.

-

Other Cummins Engines

Beyond the 6C8.3 series, this belt tensioner bracket is also compatible with a range of other Cummins engines. Its universal design allows it to be used across multiple engine models, providing a reliable solution for maintaining belt tension. This compatibility extends to various applications, from industrial machinery to agricultural equipment, showcasing the versatility of the part.

Importance of the Belt Tensioner Bracket

This part plays a pivotal role in the engine’s operation. By securing the belt tensioner in place, it ensures that the belt operates at the correct tension, which is vital for the efficient functioning of the engine’s accessories, such as the alternator, water pump, and air conditioning compressor. Proper tension prevents belt wear and reduces the risk of failure, contributing to the overall reliability and performance of the engine.

Installation and Maintenance

When installing the Belt Tensioner Bracket 3925212, it is essential to follow the manufacturer’s guidelines to ensure a secure fit. Regular maintenance checks should be performed to inspect the bracket for any signs of wear or damage. Any issues should be addressed promptly to avoid potential engine problems.

Role of Part 3925212 Belt Tensioner Bracket in Engine Systems

The 3925212 Belt Tensioner Bracket is an integral component in maintaining the proper function of the engine’s accessory drive system. This bracket is designed to support the belt tensioner, which ensures that the serpentine belt remains at the correct tension as it drives various engine accessories.

Interaction with the Alternator Drive System

When the engine is running, the serpentine belt transfers rotational force from the crankshaft to the alternator. The 3925212 Belt Tensioner Bracket plays a significant role here by securing the tensioner, which keeps the belt snugly fitted around the alternator pulley. This ensures efficient power transfer, allowing the alternator to generate electricity for the vehicle’s electrical systems.

Positioning at the Alternator Location

The alternator is typically mounted on the front or side of the engine, depending on the vehicle’s design. The 3925212 Belt Tensioner Bracket is strategically positioned to provide the necessary support and adjustment for the belt tensioner. This ensures that the belt maintains optimal contact with the alternator pulley, enhancing the alternator’s performance and reliability.

Ensuring Smooth Drive Operation

The drive system relies on the consistent and smooth operation of the serpentine belt. The 3925212 Belt Tensioner Bracket contributes to this by allowing the tensioner to automatically adjust the belt’s tension as the engine operates. This adjustment compensates for belt wear and thermal expansion, ensuring that the drive components, including the alternator, water pump, and power steering pump, receive consistent power transmission.

Maintaining Alternator Efficiency

Proper belt tension is essential for the alternator’s efficiency. If the belt is too loose, it may slip, leading to inadequate power generation. Conversely, if the belt is too tight, it can cause excessive wear on the alternator and other pulleys. The 3925212 Belt Tensioner Bracket helps maintain the ideal tension, ensuring the alternator operates within its designed parameters, thereby prolonging its service life and maintaining optimal electrical output.

Conclusion

The Belt Tensioner Bracket 3925212 by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its role in ensuring proper belt tension contributes to the efficient functioning of engine accessories, reduces wear, and enhances the overall reliability of the engine system. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.