This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

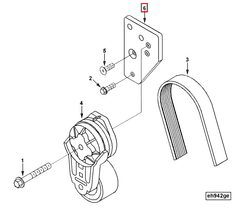

The Retaining Bracket Belt Tensioner Support Bracket, identified by Part #3925219 from Cummins, is a component designed to enhance the functionality of commercial trucks. This part plays a significant role in the operation of the truck’s engine by supporting the belt tensioner system, which is responsible for maintaining the proper tension on the engine’s accessory belts.

Basic Concepts

Understanding the Retaining Bracket Belt Tensioner Support Bracket begins with recognizing its function within the belt tensioner system. This system ensures that the belts driving various engine accessories, such as the alternator, water pump, and air conditioning compressor, remain under the correct amount of tension. The support bracket contributes to the overall performance of the truck’s engine by providing a stable mounting point for the belt tensioner, allowing it to operate efficiently 2.

Purpose and Role

The primary purpose of the Retaining Bracket Belt Tensioner Support Bracket is to support the belt tensioner and ensure that the engine’s accessory belts are maintained at the optimal tension. This is crucial for the efficient operation of the engine accessories, as belts that are too loose or too tight can lead to decreased performance, increased wear, and potential failure of the accessories. By securing the belt tensioner in place, the support bracket plays a role in maintaining the correct belt tension, which contributes to the smooth and reliable operation of the truck 3.

Key Features

The Retaining Bracket Belt Tensioner Support Bracket is designed with several key features that enhance its performance and durability. It is typically constructed from high-strength materials to withstand the rigors of commercial truck operation. The design of the bracket ensures a secure fit for the belt tensioner, minimizing movement and vibration that could affect belt tension. Additionally, the bracket may feature corrosion-resistant coatings or treatments to protect against the harsh environments often encountered by commercial trucks 4.

Benefits

Using the Retaining Bracket Belt Tensioner Support Bracket offers several benefits. It contributes to improved belt tension maintenance, which in turn enhances the performance of the engine’s accessory systems. This leads to more reliable operation of critical components such as the alternator and water pump. Furthermore, by ensuring that the belts are properly tensioned, the bracket helps to reduce wear and tear on the belts and pulleys, potentially extending their service life and reducing maintenance costs 1.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Retaining Bracket Belt Tensioner Support Bracket, regular maintenance and troubleshooting are recommended. Inspecting the bracket for signs of wear, corrosion, or damage can help identify potential issues before they lead to belt tension problems. Additionally, ensuring that the belt tensioner is properly aligned and secured by the bracket is important for maintaining correct belt tension. Regular checks and maintenance can help prevent unexpected failures and ensure the continued efficient operation of the truck’s engine accessories.

Installation and Compatibility

Proper installation of the Retaining Bracket Belt Tensioner Support Bracket is important for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper alignment with the belt tensioner. The bracket is designed to be compatible with a range of truck models and engine types, though specific compatibility details should be verified to ensure the correct fit and function for a particular application.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components and engines. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and durable automotive parts. The company’s focus on quality and performance is reflected in its wide range of products, including the Retaining Bracket Belt Tensioner Support Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Retaining Bracket Belt Tensioner Support Bracket 3925219

The Cummins Retaining Bracket Belt Tensioner Support Bracket, part number 3925219, is a critical component in the engine’s belt drive system. This part is designed to secure the belt tensioner, ensuring that the engine’s belts are properly tensioned and aligned, which is essential for the efficient operation of the engine’s ancillary systems.

Compatibility with Cummins Engines

The 3925219 retaining bracket is specifically engineered to fit various Cummins engines, including but not limited to:

- 6C8.3: This engine model benefits from the precise fit and robust construction of the 3925219 bracket, ensuring that the belt tensioner is securely mounted and operational.

The design of the 3925219 bracket allows it to integrate seamlessly with the engine’s architecture, providing a reliable mounting solution that withstands the rigors of engine operation. Its compatibility with the 6C8.3 engine ensures that the belt tensioner is held firmly in place, reducing the risk of belt slippage and maintaining optimal engine performance.

By using the 3925219 retaining bracket, engine operators can be confident that their belt drive system is secure and functioning correctly, contributing to the overall reliability and longevity of the engine.

Role of Part 3925219 Retaining Bracket Belt Tensioner Support Bracket in Engine Systems

The part 3925219 retaining bracket, specifically designed as a belt tensioner support bracket, plays a significant role in maintaining the efficiency and reliability of engine systems that incorporate a drive belt and an alternator.

Interaction with Drive Belt

The drive belt is a fundamental component in many engine systems, responsible for transferring power from the engine to various auxiliary components such as the alternator, water pump, and air conditioning compressor. The retaining bracket ensures that the belt tensioner is securely positioned, which is essential for maintaining the correct tension on the drive belt. Proper tension is vital for the efficient transfer of power and the prevention of belt slippage, which can lead to decreased performance and potential damage to the belt or connected components 2.

Support for Alternator Function

The alternator is a key component in the engine system, responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems while the engine is running. The belt tensioner support bracket, part 3925219, plays a role in ensuring that the alternator belt is correctly tensioned. This is important for the alternator to operate efficiently, as improper belt tension can lead to inefficient power generation, increased wear on the alternator, and potential failure of the electrical system 3.

Overall System Integration

Incorporating the retaining bracket into the engine system enhances the overall integration and functionality of the drive belt and alternator. By providing a stable and secure mounting point for the belt tensioner, the bracket contributes to the smooth operation of the engine system, ensuring that all components work in harmony to deliver optimal performance and reliability 4.

Conclusion

The Retaining Bracket Belt Tensioner Support Bracket, part number 3925219 from Cummins, is a vital component in the maintenance and operation of commercial truck engines. By ensuring proper tension on the engine’s accessory belts, this part contributes to the efficient and reliable operation of critical engine accessories. Its robust construction, compatibility with various engine models, and the benefits it offers in terms of performance and maintenance make it an essential part of the engine system. Regular maintenance and proper installation are key to maximizing the effectiveness of this Cummins part.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ ↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.