This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

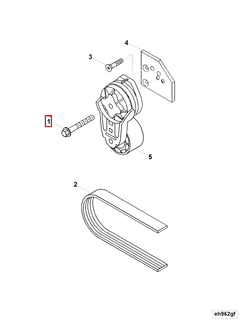

The Belt Tensioner Bracket, part number 3926873, manufactured by Cummins, is a critical component designed to support the efficient operation of commercial trucks. Cummins, a well-established name in the automotive industry, produces this bracket to ensure the reliable performance of truck engines. This part is integral to maintaining the proper tension of belts within the engine system, which is vital for the overall functionality and longevity of the truck 1.

Function and Operation

The Belt Tensioner Bracket operates by securing the tensioner assembly in place, allowing it to apply the correct amount of pressure to the belts. This ensures that the belts run smoothly and efficiently, reducing the risk of slippage or breakage. The bracket’s design enables it to withstand the dynamic forces exerted by the tensioner, contributing to consistent belt tension throughout the engine’s operation 2.

Key Features

This Cummins part is crafted from high-strength materials, ensuring durability and resistance to wear. Its design incorporates precise engineering to accommodate the tensioner’s movement while maintaining a secure fit. The bracket’s construction allows for easy installation and replacement, facilitating maintenance procedures. Additionally, its robust build helps protect against corrosion and environmental factors, enhancing its longevity in various operating conditions 3.

Benefits

Utilizing the Belt Tensioner Bracket offers several advantages. It contributes to improved engine efficiency by ensuring that belts operate within their optimal tension range. This reduces the likelihood of belt wear and tear, leading to fewer replacements and lower maintenance costs. Moreover, the bracket enhances the overall reliability of the truck’s engine system, promoting smoother operation and potentially extending the engine’s lifespan.

Installation and Compatibility

When installing the Belt Tensioner Bracket, it is important to follow manufacturer guidelines to ensure proper fitment and function. Compatibility with specific truck models should be verified to guarantee optimal performance. Careful attention to torque specifications and alignment during installation will help maintain the integrity of the bracket and the tensioner assembly.

Maintenance and Troubleshooting

Regular maintenance of the Belt Tensioner Bracket is recommended to ensure its continued performance. This includes periodic inspections for signs of wear, corrosion, or damage. If issues such as unusual noise or belt slippage are detected, it may indicate a problem with the bracket or the tensioner. Troubleshooting steps should involve checking the bracket’s condition, ensuring proper tensioner operation, and addressing any identified issues promptly.

Safety Considerations

When working with the Belt Tensioner Bracket, it is important to observe safety precautions. This includes wearing appropriate personal protective equipment, ensuring the engine is off and cool before beginning any work, and following all manufacturer-recommended procedures. Regular inspections and maintenance should be conducted according to established intervals to prevent unexpected failures and ensure safe operation.

Cummins Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for its commitment to quality, Cummins produces a wide range of components designed to enhance the performance and reliability of engines. The company’s dedication to innovation and excellence is reflected in its products, including the Belt Tensioner Bracket, which is engineered to meet the demanding requirements of commercial truck applications.

Compatibility with Cummins Engines

The Belt Tensioner Bracket, part number 3926873, is designed to fit a variety of Cummins engines. This bracket plays a role in maintaining the proper tension of the engine’s belts, ensuring efficient operation and longevity of the belt system.

6C8.3

The 6C8.3 engine benefits from the Belt Tensioner Bracket, which helps in maintaining the correct tension of the belts, ensuring smooth and reliable engine performance.

C GAS PLUS CM556

In the C GAS PLUS CM556 engine, the Belt Tensioner Bracket is integral for the proper functioning of the belt system. It ensures that the belts are held securely in place, preventing slippage and reducing wear and tear.

C8.3 G

For the C8.3 G engine, the Belt Tensioner Bracket is essential for maintaining the tension of the belts. This bracket ensures that the belts operate efficiently, contributing to the overall reliability and performance of the engine.

These engines, while differing in their specific applications and configurations, all rely on the Belt Tensioner Bracket to maintain optimal belt tension, ensuring that the engine operates smoothly and efficiently.

Role of Belt Tensioner Bracket in Engine Systems

The Belt Tensioner Bracket, identified by part number 3926873, is integral to the efficient operation of various engine components. It is primarily responsible for maintaining the correct tension on the drive belt, which is essential for the proper functioning of peripheral engine components.

Interaction with the Alternator Drive

When the Belt Tensioner Bracket is correctly installed, it ensures that the drive belt is appropriately tensioned as it wraps around the alternator pulley. This tension is vital for the alternator to effectively convert mechanical energy from the engine into electrical energy. Without proper tension, the belt may slip, leading to inefficient power generation and potential alternator failure.

Coordination with the Drive System

The drive system, which includes various pulleys and the drive belt itself, relies on the Belt Tensioner Bracket to maintain consistent tension. This is particularly important for components that require a steady supply of mechanical power, such as the water pump and the air conditioning compressor. The bracket’s role in tension management helps prevent belt wear and tear, ensuring longevity and reliable performance of the drive system.

Ensuring Alternator Efficiency

By keeping the drive belt taut, the Belt Tensioner Bracket directly influences the alternator’s efficiency. A well-tensioned belt allows the alternator to spin at the optimal speed, maximizing its output. This is essential for maintaining the vehicle’s electrical systems, including lighting, ignition, and various electronic controls, under all operating conditions.

Conclusion

In summary, the Belt Tensioner Bracket (part 3926873) plays a significant role in the harmonious operation of the alternator drive and the overall drive system, ensuring that all components receive the necessary power to function correctly. Its design and functionality contribute to the reliability and efficiency of commercial truck engines, making it a vital component in the maintenance and performance of these vehicles.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.