This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

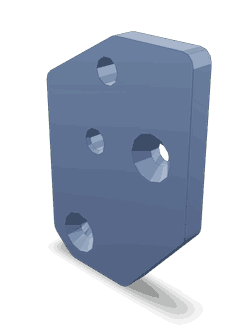

The Belt Tensioner Bracket, identified by Part #3933405, is a component manufactured by Cummins, a well-established name in the automotive industry. This Cummins part plays a significant role in the operation of heavy-duty trucks by ensuring the proper functioning of the belt tensioner system. Its design and construction are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall efficiency and reliability of the truck’s engine system 1.

Function and Operation

The Belt Tensioner Bracket operates within the truck’s engine system by supporting the belt tensioner, which maintains the correct tension on the engine’s drive belts. These belts are responsible for driving various engine accessories, such as the alternator, water pump, and air conditioning compressor. The bracket ensures that the tensioner can move freely and apply the necessary force to keep the belts taut, which is vital for the efficient transfer of power and the smooth operation of engine accessories 2.

Key Features

The Belt Tensioner Bracket is characterized by several key features that enhance its performance and durability. It is typically constructed from high-strength materials, such as cast iron or steel, to withstand the rigors of heavy-duty use. The design of the bracket allows for precise alignment and secure mounting of the tensioner, ensuring optimal belt tension. Additionally, the bracket may incorporate features such as vibration dampening elements to reduce noise and wear, and corrosion-resistant coatings to prolong its service life in harsh environments 3.

Benefits of Using a Belt Tensioner Bracket

Incorporating a Belt Tensioner Bracket into the truck’s engine system offers several advantages. It contributes to improved belt longevity by maintaining consistent tension, which reduces the risk of belt slippage and premature wear. This, in turn, leads to reduced wear and tear on the engine’s drive components and enhances overall engine performance. The bracket also plays a role in minimizing vibrations and noise, contributing to a smoother and more reliable engine operation 4.

Installation Process

Proper installation of the Belt Tensioner Bracket is crucial for its effective operation. The process typically involves securing the bracket to the engine block or frame using the provided mounting hardware. It is important to ensure that the bracket is aligned correctly and that the tensioner is installed according to the manufacturer’s specifications. This may include adjusting the tensioner to achieve the correct belt tension, as outlined in the vehicle’s service manual.

Maintenance and Troubleshooting

Regular maintenance of the Belt Tensioner Bracket is important to ensure its continued reliable operation. This includes periodic inspection for signs of wear, corrosion, or damage, and ensuring that the tensioner moves freely without obstruction. Common issues may include belt slippage, unusual noises, or visible wear on the bracket or tensioner. Troubleshooting these issues may involve adjusting the tensioner, replacing worn components, or addressing any underlying problems with the engine’s drive system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product offerings cater to various applications, from on-highway and off-highway vehicles to industrial and marine applications. Cummins’ commitment to excellence is reflected in the design and manufacturing of components like the Belt Tensioner Bracket, ensuring they meet the high standards required for heavy-duty use.

Belt Tensioner Bracket 3933405 Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 3933405, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s belt system, ensuring optimal performance and longevity of the engine components.

Compatible Engines

-

4B3.9 and 6B5.9 The 3933405 Belt Tensioner Bracket is specifically engineered to fit the 4B3.9 and 6B5.9 engines. These engines are known for their reliability and efficiency, and the bracket ensures that the belt system operates smoothly, reducing wear and tear on the belt and related components.

-

B5.9 G and B5.9 GAS PLUS CM556 The same part number, 3933405, is also compatible with the B5.9 G and B5.9 GAS PLUS CM556 engines. These engines, while sharing similarities with the 4B3.9 and 6B5.9, have specific design nuances that the bracket accommodates. The bracket’s design allows for precise alignment and tensioning, which is critical for the performance of these engines.

Installation and Usage

When installing the 3933405 Belt Tensioner Bracket, it is essential to follow the manufacturer’s guidelines to ensure proper fitment and function. This includes checking for any necessary adjustments or modifications specific to the engine model. Proper installation will help maintain the integrity of the belt system, preventing issues such as belt slippage or premature wear.

Importance of the Belt Tensioner Bracket

The Belt Tensioner Bracket plays a vital role in the engine’s belt system by ensuring that the belt remains taut and properly aligned. This is crucial for the efficient transfer of power from the engine to the various components it drives, such as the alternator, water pump, and air conditioning compressor. A well-functioning belt system contributes to the overall reliability and performance of the engine.

Role of Part 3933405 Belt Tensioner Bracket in Engine Systems

The Belt Tensioner Bracket, identified by part number 3933405, is an integral component in maintaining the proper function and efficiency of various engine systems. This bracket is specifically designed to support the belt tensioner, which in turn ensures that the drive belts are kept at the correct tension.

In the context of the alternator drive system, the Belt Tensioner Bracket plays a significant role. It secures the tensioner in place, allowing it to apply the necessary force to the alternator drive belt. This ensures that the belt runs smoothly and efficiently, minimizing slippage and wear. Proper tension is essential for the alternator to operate effectively, as it relies on the consistent rotation of the belt to generate electricity for the vehicle’s electrical systems.

Similarly, in systems involving other drive components, such as the water pump or power steering pump, the Belt Tensioner Bracket ensures that the belts remain taut. This is important for the efficient transfer of power from the engine to these auxiliary components. Without adequate tension, the belts could slip, leading to reduced efficiency and potential damage to the components they drive.

Conclusion

In summary, the Belt Tensioner Bracket (part 3933405) is a key element in the maintenance of drive belt systems, ensuring that all connected components, including the alternator and other drives, function smoothly and reliably. Its role in maintaining proper belt tension is crucial for the efficient operation of engine accessories and the overall performance of the engine system.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.