This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

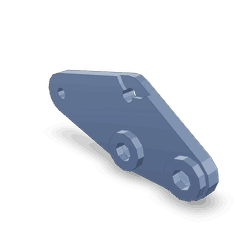

The Belt Tensioner Support Bracket, part number 3968137, manufactured by Cummins, is a component designed to facilitate the operation of commercial trucks. This bracket plays a role in the engine system by providing a stable mounting point for the belt tensioner, which in turn ensures that the drive belts maintain the correct tension. Proper tensioning of the belts is vital for the efficient operation of the engine and other driven components, such as the alternator, water pump, and air conditioning compressor 1.

Basic Concepts of Belt Tensioner Support Bracket

A Belt Tensioner Support Bracket is a structural component that supports the belt tensioner within the engine system. Its primary function is to hold the tensioner in place, allowing it to apply the necessary force to keep the drive belts at the optimal tension. This bracket interacts with other components such as the belt tensioner and drive belts, ensuring that they operate within specified parameters. The tensioner, in conjunction with the bracket, adjusts the position of the belts to compensate for wear and thermal expansion, maintaining consistent tension throughout the engine’s operation 2.

Purpose of the Belt Tensioner Support Bracket

The Belt Tensioner Support Bracket part #3968137 is instrumental in maintaining proper tension on the drive belts. By securely mounting the belt tensioner, it allows for the automatic adjustment of belt tension as the belts wear or as temperatures change. This contributes to the efficient operation of the engine and other driven components by ensuring that the belts do not slip or become overly tight, which could lead to premature wear or failure 3.

Key Features

The Belt Tensioner Support Bracket part #3968137 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the harsh conditions within the engine compartment. The bracket includes precise mounting points that ensure accurate alignment of the belt tensioner. Additionally, it may incorporate unique design elements such as vibration dampening features to reduce noise and wear on the tensioner and belts.

Benefits

Using the Belt Tensioner Support Bracket in commercial trucks offers several advantages. It contributes to improved belt longevity by ensuring consistent tension, which reduces the risk of belt failure. This, in turn, leads to reduced maintenance requirements, as belts are less likely to need adjustment or replacement. Furthermore, the bracket enhances engine performance by supporting the efficient operation of driven components, which rely on properly tensioned belts to function correctly.

Installation Process

Installing the Belt Tensioner Support Bracket requires careful attention to detail to ensure optimal performance. The process involves aligning the bracket with the designated mounting points on the engine and securing it in place. It is important to follow the manufacturer’s instructions for torque specifications when tightening fasteners to avoid over-tightening, which could damage the bracket or engine components. Correct alignment and secure mounting are crucial for the bracket to perform its intended function effectively.

Troubleshooting and Maintenance

Common issues with the Belt Tensioner Support Bracket may include misalignment, wear, or damage to the mounting points. These issues can be identified through regular inspection and maintenance. To ensure longevity and proper function, it is recommended to inspect the bracket during routine maintenance checks, clean it to remove any debris or buildup, and replace it if signs of wear or damage are present. Proper maintenance of the bracket will help to prevent issues with the belt tensioner and drive belts.

Compatibility and Application

The Belt Tensioner Support Bracket part #3968137 is designed for use in specific types of commercial trucks and engine models. It is commonly applied in environments where reliable and efficient engine operation is critical. The bracket’s design takes into account various driving conditions and environments, ensuring that it can withstand the demands placed upon it in commercial truck applications.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the commercial truck industry. The company is known for its commitment to quality and innovation in engine components. Cummins has a history of developing reliable and high-performance parts that meet the needs of commercial truck operators. Their products, including the Belt Tensioner Support Bracket part #3968137, are designed with precision engineering and rigorous testing to ensure they deliver consistent performance and durability in demanding applications.

Compatibility with Cummins Engines

The Belt Tensioner Support Bracket 3968137 is specifically engineered to fit seamlessly with several Cummins engine models. Here is a detailed look at the compatibility of this part with various Cummins engines:

- 6C8.3 Engine Series: This part is integral to the 6C8.3 engine series, providing the necessary support for the belt tensioner. The 6C8.3 engine is known for its robust performance and reliability, often used in heavy-duty applications such as construction and agricultural equipment.

The Belt Tensioner Support Bracket 3968137 is designed to maintain the integrity of the belt system, ensuring that the belts remain properly tensioned and aligned. This is crucial for preventing belt slippage, which can lead to reduced efficiency and potential damage to engine components.

By integrating this support bracket into the engine’s design, Cummins ensures that the belt system operates smoothly, contributing to the overall longevity and performance of the engine. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Role of Part 3968137 Belt Tensioner Support Bracket in Engine Systems

The Belt Tensioner Support Bracket, identified by part number 3968137, is an integral component in maintaining the proper function of the front engine support system. This bracket is designed to secure the belt tensioner, ensuring that the serpentine belt remains under the correct tension.

In the context of the front engine support, the bracket plays a significant role in stabilizing the tensioner. It allows for the efficient transfer of force from the tensioner to the engine block, which is essential for the consistent operation of the belt-driven accessories such as the alternator, power steering pump, and air conditioning compressor.

The bracket’s placement and design contribute to the overall durability and reliability of the engine’s accessory drive system. By providing a solid mounting point for the tensioner, it helps to reduce vibrations and wear on the belt, leading to a more stable and longer-lasting performance of the engine’s auxiliary components.

Additionally, the support bracket aids in the ease of maintenance and replacement of the belt tensioner. Its strategic location allows for straightforward access, which is beneficial during routine inspections or when performing repairs on the engine’s drive belt system.

Conclusion

The Belt Tensioner Support Bracket part #3968137 is a critical component in the engine’s belt drive system, ensuring the proper alignment and tension of the engine belts. Its compatibility with various Cummins engine models, including the 6C8.3 series, underscores its importance in maintaining engine efficiency and reliability. The bracket’s design and features contribute to the durability and performance of the engine’s accessory drive system, making it a valuable component in the operation of commercial trucks.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavy-duty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.