This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

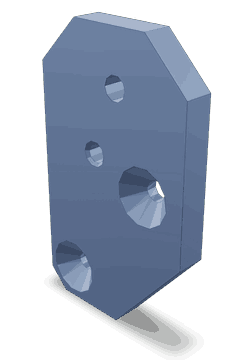

The Belt Tensioner Bracket, identified by Part #4063775, is a component manufactured by Cummins, a well-established name in the automotive industry. This bracket is integral to the operation of heavy-duty trucks, ensuring the efficient functioning of the engine’s belt system. Cummins, known for its robust and reliable components, provides this part as part of its extensive range of products designed for heavy-duty applications.

Function and Operation

The Belt Tensioner Bracket operates within the truck’s engine system by maintaining the appropriate tension on the engine’s belts. This tension is vital for the belts to function correctly, driving various engine components such as the alternator, water pump, and air conditioning compressor. The bracket houses the tensioner mechanism, which automatically adjusts to keep the belt at the correct tension, compensating for wear and temperature changes 1.

Key Features

The design of the Belt Tensioner Bracket by Cummins incorporates several features that enhance its performance and durability. Constructed from high-strength materials, the bracket is resistant to the harsh conditions typically encountered in heavy-duty truck environments. Its design allows for easy installation and integration with the engine’s belt system, ensuring a secure fit and reliable operation. Additionally, the bracket’s surface may feature treatments or coatings to resist corrosion and wear, further extending its service life 2.

Benefits of Using a Belt Tensioner Bracket

Incorporating a Belt Tensioner Bracket into a truck’s engine system offers several advantages. It contributes to the prolonged lifespan of the belts by maintaining consistent tension, which reduces the risk of belt slippage or breakage. This, in turn, leads to reduced maintenance requirements and lowers the likelihood of unexpected downtime. Furthermore, proper belt tension enhances the overall performance of the engine, ensuring that driven components operate efficiently 3.

Installation Process

Installing the Belt Tensioner Bracket requires careful attention to detail to ensure proper function. The process involves securing the bracket to the engine block using the provided fasteners, ensuring it is aligned correctly with the belt’s path. It is important to use the correct tools for tightening fasteners to the specified torque settings to avoid over-tightening, which could damage the bracket or engine components. After installation, it is recommended to inspect the belt tension to confirm it is within the manufacturer’s specifications.

Common Issues and Troubleshooting

Typical problems associated with Belt Tensioner Brackets include wear on the tensioner mechanism, misalignment due to improper installation, and corrosion. If the tensioner shows signs of wear, such as excessive play or noise, it may need adjustment or replacement. Misalignment can often be corrected by re-positioning the bracket or adjusting the tensioner. Corrosion can be mitigated by applying a protective coating or replacing the bracket if damage is severe.

Maintenance Tips

To ensure the optimal performance of the Belt Tensioner Bracket, regular inspections are recommended. This includes checking for signs of wear on the tensioner, ensuring the bracket is securely fastened, and verifying that the belt tension remains consistent. Any signs of damage or excessive wear should be addressed promptly to prevent further issues. Additionally, keeping the bracket and surrounding areas clean can help prevent the accumulation of debris that could interfere with its operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes engines and components for on-highway and off-highway applications, with a strong focus on heavy-duty trucks. Cummins’ commitment to excellence is reflected in its components, which are designed to meet the demanding requirements of heavy-duty operations.

Belt Tensioner Bracket 4063775 for Cummins Engines

The Belt Tensioner Bracket 4063775, manufactured by Cummins, is a critical component in the engine’s belt drive system. This part is designed to maintain proper tension on the engine’s serpentine belt, ensuring efficient power transfer from the engine to various ancillary components such as the alternator, water pump, and air conditioning compressor.

Compatibility with Cummins Engines

-

6B5.9 Engine Series

The Belt Tensioner Bracket 4063775 is specifically engineered to fit seamlessly within the 6B5.9 engine series. This compatibility ensures that the bracket maintains the correct alignment and tension of the serpentine belt, which is crucial for the engine’s optimal performance and longevity.

The 6B5.9 engine series is known for its robust design and reliability, often used in heavy-duty applications. The Belt Tensioner Bracket 4063775 is designed to withstand the rigors of these demanding environments, providing a durable and long-lasting solution for maintaining belt tension.

Installation and Functionality

While the specific installation procedures may vary depending on the engine model, the Belt Tensioner Bracket 4063775 is typically mounted on the engine block or frame. Its primary function is to secure the belt tensioner assembly in place, ensuring that the belt remains taut and does not slip or come off during operation.

Importance in Engine Performance

Maintaining the correct belt tension is vital for the efficient operation of the engine. An improperly tensioned belt can lead to increased wear on the belt and driven components, reduced power output, and potential engine damage. The Belt Tensioner Bracket 4063775 plays a role in preventing these issues by ensuring that the belt remains properly tensioned at all times.

Reliability and Durability

Cummins is renowned for producing high-quality, durable components that meet the stringent demands of heavy-duty applications. The Belt Tensioner Bracket 4063775 is no exception, featuring materials and design elements that ensure long-lasting performance even in the most challenging operating conditions.

Conclusion

The Belt Tensioner Bracket, identified by part number 4063775, is an integral component in maintaining the optimal operation of the alternator drive system within an engine. This bracket securely mounts the belt tensioner, which is responsible for applying the correct amount of tension to the drive belt. Proper tension ensures efficient power transmission from the engine to the alternator, facilitating consistent electrical output and reliable engine performance.

In the context of the alternator drive, the Belt Tensioner Bracket works in conjunction with the drive belt to regulate the rotational speed of the alternator. This regulation is essential for the alternator to generate a stable electrical current, which powers the vehicle’s electrical systems and recharges the battery. Without adequate tension, the drive belt may slip, leading to inefficient power transfer and potential alternator failure.

Additionally, the Belt Tensioner Bracket plays a role in reducing wear and tear on both the drive belt and the alternator. By maintaining consistent tension, it prevents the belt from becoming overly tight or loose, which can cause premature degradation of the belt material and increased stress on the alternator bearings.

In summary, the Belt Tensioner Bracket (part 4063775) is a key component in ensuring the smooth and efficient operation of the alternator drive system, contributing to the overall reliability and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.