This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

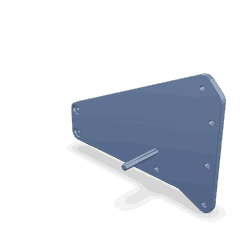

The 4974176 Belt Tensioner Bracket, manufactured by Cummins, is a component designed to support the efficient operation of commercial trucks. Cummins, a well-established name in the automotive industry, produces this part to ensure the reliable performance of truck engines. This bracket is integral to maintaining the proper tension of the belts within the engine system, which is vital for the overall functionality and efficiency of the vehicle 1.

Basic Concepts of Belt Tensioner Brackets

A Belt Tensioner Bracket is a mechanical component that holds the tensioner pulley in place. Its primary function is to maintain the correct tension on the belts that drive various engine accessories, such as the alternator, water pump, and air conditioning compressor. Proper belt tension is essential for the efficient transfer of power and to prevent belt slippage, which can lead to decreased performance and potential damage to the engine components 2.

Purpose of the 4974176 Belt Tensioner Bracket

The 4974176 Belt Tensioner Bracket plays a role in the operation of a truck by ensuring that the belts remain taut under varying engine conditions. This contributes to consistent engine performance and efficiency. By maintaining optimal belt tension, the bracket helps in reducing the wear and tear on the belts and the components they drive, thereby supporting the longevity and reliability of the engine system 3.

Key Features

The 4974176 Belt Tensioner Bracket is constructed with high-quality materials to ensure durability and performance. Its design includes precise engineering to accommodate the tensioner pulley securely. The bracket is built to withstand the rigors of commercial truck operation, featuring robust construction that enhances its functionality and reliability in demanding environments.

Benefits

The advantages of using the 4974176 Belt Tensioner Bracket include improved belt longevity due to consistent tension, which reduces the frequency of belt replacements. Additionally, it contributes to reduced maintenance requirements by ensuring that the belts operate efficiently. Enhanced engine performance is another benefit, as proper belt tension leads to better power transmission and overall engine reliability.

Installation Process

Installing the 4974176 Belt Tensioner Bracket requires careful attention to ensure a secure fit. The process involves aligning the bracket with the mounting points on the engine, securing it with the appropriate fasteners, and ensuring that the tensioner pulley is correctly positioned. Using the right tools and following best practices during installation will help in achieving optimal performance and longevity of the bracket and the belts it supports.

Troubleshooting Common Issues

Common problems with Belt Tensioner Brackets may include misalignment or wear over time. To address these issues, it is important to inspect the bracket and tensioner regularly for signs of damage or improper positioning. Corrective actions may involve realigning the bracket, replacing worn components, or adjusting the tensioner to maintain the correct belt tension.

Maintenance Tips

To keep the 4974176 Belt Tensioner Bracket in optimal condition, routine maintenance practices should be followed. This includes regular inspections for signs of wear or damage, ensuring that the bracket and tensioner are properly aligned, and checking the belt tension periodically. Addressing any issues promptly will help in maintaining the efficiency and reliability of the engine system.

Cummins: Manufacturer Overview

Cummins Inc. is a leader in the automotive industry, known for its commitment to producing high-quality components. With a rich history of innovation and excellence, Cummins has established a reputation for reliability and performance. The company’s dedication to quality is evident in its products, including the 4974176 Belt Tensioner Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Belt Tensioner Bracket 4974176 Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 4974176, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s belts, ensuring efficient operation and longevity of the engine components.

ISM Series Engines

- ISM CM570: The Belt Tensioner Bracket 4974176 is compatible with the ISM CM570 engine, providing a secure mounting point for the belt tensioner.

- ISM CM570/870: This bracket is also suitable for the ISM CM570/870 engine, which combines the features of both the CM570 and CM876 models.

- ISM CM876: The ISM CM876 engine is another model that can utilize the 4974176 Belt Tensioner Bracket, ensuring the belt system operates smoothly.

- ISM11 CM876 SN: This engine variant also fits the 4974176 bracket, maintaining the integrity of the belt tensioning system.

M11 Series Engines

- M11 CELECT: The M11 CELECT engine is designed to work with the 4974176 Belt Tensioner Bracket, facilitating precise belt tension management.

- M11 CELECT PLUS: This enhanced version of the M11 CELECT engine is also compatible with the 4974176 bracket, offering the same reliable performance.

- M11 MECHANICAL: The M11 MECHANICAL engine can use the 4974176 Belt Tensioner Bracket, ensuring the belt system is properly tensioned for optimal engine operation.

QSM11 Series Engine

- QSM11 CM570: The QSM11 CM570 engine is another model that fits the 4974176 Belt Tensioner Bracket, ensuring the belt tensioning system functions correctly.

This compatibility ensures that the Belt Tensioner Bracket 4974176 can be used across various Cummins engine models, providing a standardized solution for maintaining belt tension.

Role of Part 4974176 Belt Tensioner Bracket in Engine Systems

The part 4974176 Belt Tensioner Bracket is integral to maintaining the proper tension of the drive belt within engine systems. This ensures efficient operation of various components driven by the belt, such as the refrigerant compressor and the alternator.

Interaction with Mounting Components

The Belt Tensioner Bracket interfaces with the engine’s mounting structure. It is securely fastened to the engine block or a designated mounting point. This stable attachment allows it to effectively apply consistent tension to the drive belt, compensating for any wear or stretch that may occur over time. The bracket’s precise alignment with the mounting points is essential for the tensioner’s function, ensuring that the belt remains properly engaged with all pulleys.

Coordination with Refrigerant Compressor

In systems where the refrigerant compressor is belt-driven, the Belt Tensioner Bracket plays a significant role. It ensures that the drive belt maintains optimal tension as it wraps around the compressor’s pulley. This is important for the compressor’s efficient operation, as proper belt tension prevents slippage, which can lead to inefficient cooling performance and increased wear on the compressor.

The consistent tension provided by the Belt Tensioner Bracket also aids in reducing noise and vibration within the engine compartment. This is particularly beneficial in systems where the refrigerant compressor operates at varying speeds, as the tensioner can adjust to maintain belt tension across different operational conditions.

Conclusion

In summary, the Belt Tensioner Bracket is a key component in ensuring the drive belt operates efficiently within the engine system, directly impacting the performance of connected components like the refrigerant compressor. Proper maintenance and installation of this Cummins part are crucial for the longevity and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.