This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3924026 Belt Tensioner is designed to maintain the proper tension of the serpentine belt in commercial trucks. This ensures that the belt remains securely in place and operates efficiently, contributing to the overall performance and reliability of the truck’s engine system.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the serpentine belt at the correct tension. It applies consistent pressure to the belt, preventing slippage and ensuring effective power transmission to driven accessories such as the alternator, water pump, and air conditioning compressor. Proper belt tension is essential for the efficient operation of these components and the longevity of the belt itself 1.

Role of the 3924026 Belt Tensioner in Truck Operation

The 3924026 Belt Tensioner ensures that the serpentine belt remains taut, interacting with the belt, pulleys, and driven accessories to maintain optimal performance. Proper tension allows for smooth operation of the accessories, which is vital for the truck’s engine system to function correctly 2.

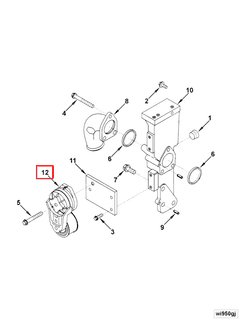

Key Features of the 3924026 Belt Tensioner

The design and construction of the 3924026 Belt Tensioner include high-quality materials and a mechanism that ensures consistent tension on the belt. It is built to withstand the rigors of commercial truck operation, featuring durable components that enhance its performance and longevity. The tensioner’s unique attributes contribute to its reliability and effectiveness in maintaining belt tension 3.

Benefits of Using the 3924026 Belt Tensioner

Using the 3924026 Belt Tensioner provides several advantages. It contributes to improved efficiency by ensuring that the serpentine belt operates within the optimal tension range. This results in reduced wear on both the belt and the pulleys, leading to enhanced reliability of the truck’s accessory systems. The tensioner’s design also helps in minimizing noise and vibration, which can be associated with a loose or worn belt 4.

Installation and Compatibility

Proper installation of the 3924026 Belt Tensioner is essential for ensuring its effectiveness and compatibility with various truck models and engine configurations. Specific guidelines should be followed to ensure that the tensioner is correctly positioned and secured. This includes verifying that all mounting points are properly aligned and that the tensioner is able to move freely within its operational range.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, slippage, or premature wear. These issues can often be identified through routine inspections and diagnostic checks. Solutions may involve adjusting the tensioner, replacing worn components, or ensuring that the serpentine belt is in good condition. Addressing these problems promptly can help maintain the efficiency and reliability of the truck’s engine system.

Maintenance Tips

Routine maintenance practices are essential for ensuring the longevity and optimal performance of the 3924026 Belt Tensioner. This includes regular inspections to check for signs of wear or damage, ensuring that the tensioner moves freely, and verifying that the serpentine belt is properly tensioned. Lubrication guidelines should be followed to reduce friction and wear on moving parts. Replacement criteria should be based on the manufacturer’s recommendations or when signs of significant wear are observed.

Engines Compatible with Belt Tensioner 3924026

Group 1: 4B3.9, 6B5.9, B5.9 G

The Belt Tensioner 3924026 is compatible with the 4B3.9, 6B5.9, and B5.9 G engines. These engines, while differing in size and power output, share a similar design that allows the tensioner to fit seamlessly, maintaining the necessary belt tension across various operational conditions.

Group 2: B5.9 GAS PLUS CM556, ISB CM550

The B5.9 GAS PLUS CM556 and ISB CM550 engines also utilize the Belt Tensioner 3924026. These engines, which may be found in a range of applications from industrial to transportation, benefit from the tensioner’s ability to adapt to the specific demands of gas-powered systems, ensuring smooth and reliable operation.

Group 3: ISB5.9G CM2180

The ISB5.9G CM2180 engine is another model that is compatible with the Belt Tensioner 3924026. This engine, known for its robust performance and efficiency, requires a tensioner that can handle the unique stresses and requirements of its design, which the 3924026 model effectively provides.

Compatibility and Functionality

The Belt Tensioner 3924026 is engineered to fit these engines by providing a consistent and reliable method of belt tensioning. It is designed to withstand the operational stresses of the engines, ensuring that the belt remains properly tensioned to prevent slippage and maintain the efficiency of the engine’s ancillary systems.

Role of Part 3924026 Belt Tensioner in Engine Systems

Interaction with the Pulley System

The Belt Tensioner works in conjunction with the pulley system to maintain the necessary tension on the belts. This is particularly important for belts that drive components such as the alternator, power steering pump, and air conditioning compressor. Proper tension ensures that these belts do not slip, which could lead to inefficient operation or complete failure of the driven components.

Connection to the Water Pump Drive

In engines where the water pump is belt-driven, the Belt Tensioner plays a significant role in ensuring that the belt remains taut. This is essential for the water pump to operate efficiently, maintaining proper coolant flow through the engine. Inadequate tension can result in reduced coolant circulation, potentially leading to overheating and engine damage.

Influence on the Water Inlet System

The efficiency of the water inlet system, which introduces coolant into the engine, is indirectly affected by the Belt Tensioner. Since the water pump drive belt must be properly tensioned to ensure consistent coolant flow, the Belt Tensioner contributes to the stable operation of the water inlet system. This stability is crucial for maintaining optimal engine temperature and preventing thermal stress on engine components.

Overall Engine Performance

By ensuring that all belts are maintained at the correct tension, the 3924026 Belt Tensioner contributes to the overall performance and reliability of the engine. It helps in reducing wear and tear on the belts and the components they drive, leading to longer service intervals and enhanced engine longevity.

Conclusion

The Cummins 3924026 Belt Tensioner is a critical component in maintaining the proper tension of the serpentine belt in commercial trucks. Its role in ensuring efficient operation and longevity of the belt and related components is essential for the overall performance and reliability of the truck’s engine system. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this Cummins part.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022.

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000.

↩ -

Modeling Engine Spray and Combustion Processes, Gunnar Stiesch, Springer Verlag, 2003.

↩ -

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.