This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3936212 Belt Tensioner is a component designed for use in commercial trucks. Its purpose is to maintain the correct tension on the drive belts within the engine system. This ensures efficient operation and longevity of the belts, contributing to the overall performance and reliability of the truck 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at the proper tension. It functions by automatically adjusting the tension on the belts as they stretch or wear over time. Maintaining proper belt tension is important for ensuring that the belts drive various engine components effectively, reducing the risk of slippage and wear 2.

Purpose of the Cummins 3936212 Belt Tensioner

This Cummins part plays a role in the operation of a truck by maintaining the correct tension on the drive belts. This function is vital for the efficient transfer of power from the engine to components such as the alternator, water pump, and air conditioning compressor. Proper tension ensures these components operate smoothly and efficiently 3.

Key Features

The 3936212 is characterized by several key features that enhance its performance. It is designed with precision engineering to ensure accurate tension maintenance. The tensioner is constructed from durable materials to withstand the harsh conditions of commercial truck operation. Additionally, it incorporates design elements that facilitate easy installation and maintenance 4.

Benefits

Using the 3936212 offers several benefits. It contributes to improved engine efficiency by ensuring that the drive belts operate under optimal tension. This reduces wear on the belts and the components they drive, leading to enhanced reliability and longevity of the engine system. Moreover, proper belt tension helps in minimizing noise and vibration, contributing to a smoother operation of the truck.

Installation Process

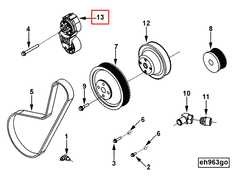

Installing the 3936212 involves several steps. First, the old tensioner, if present, should be removed. This may require loosening the belt and disengaging it from the pulleys. The new tensioner is then positioned in place and secured according to the manufacturer’s instructions. Tools such as wrenches and socket sets may be required. It is important to ensure that the tensioner is properly aligned and tightened to the specified torque settings.

Troubleshooting Common Issues

Common issues with the 3936212 may include belt slippage, unusual noises, or visible wear on the tensioner or belts. Troubleshooting steps involve inspecting the tensioner for signs of damage or misalignment, checking the condition of the belts, and ensuring that the tensioner is properly installed and tightened. Solutions may range from simple adjustments to replacement of the tensioner or belts.

Maintenance Tips

To ensure the longevity and optimal performance of the 3936212, regular maintenance is recommended. This includes periodic inspection of the tensioner and belts for signs of wear or damage. Belts should be replaced according to the manufacturer’s guidelines or when signs of wear are evident. The tensioner itself should be checked for proper operation and alignment during routine maintenance checks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses.

Belt Tensioner 3936212 Compatibility with Cummins Engines

The Belt Tensioner part number 3936212, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and related components.

ISC Series Engines

The Belt Tensioner 3936212 is compatible with several models within the ISC series:

- ISC CM2150

- ISC CM554

- ISC CM850

These engines are known for their robust performance and are often used in heavy-duty applications.

ISL Series Engines

The Belt Tensioner 3936212 is also suitable for the following ISL series engines:

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series is recognized for its high power output and reliability, making it a popular choice in various industries.

Other Cummins Engines

In addition to the ISC and ISL series, the Belt Tensioner 3936212 fits the following engines:

- 6C8.3

- B6.7S

- C8.3 G

- C GAS PLUS CM556

- QSB5.9 CM550

These engines span a range of applications, from agricultural to industrial uses, and the Belt Tensioner 3936212 ensures that the serpentine belt remains properly tensioned across all these models.

Role of Part 3936212 Belt Tensioner in Engine Systems

The 3936212 Belt Tensioner is an integral component in maintaining the efficiency and reliability of various engine systems. It ensures that the belts driving essential components are kept at the optimal tension, which is vital for their performance and longevity.

Interaction with the Alternator

At the alternator location, the Belt Tensioner works in conjunction with the alternator pulley to maintain the correct tension on the drive belt. This ensures that the alternator receives consistent power from the engine, allowing it to efficiently charge the battery and power the electrical systems of the vehicle.

Drive System Integration

In the drive system, the Belt Tensioner plays a key role by keeping the drive belt properly tensioned. This is essential for the smooth operation of components such as the alternator and water pump. Proper tension prevents slippage, which can lead to inefficient operation and potential damage to the belt and driven components.

Water Pump Drive

The water pump drive relies on the Belt Tensioner to maintain the necessary tension on the belt that drives the water pump. This ensures that the water pump operates efficiently, providing consistent coolant flow through the engine to maintain optimal operating temperatures.

Service Kits and Maintenance

In 50 DN service kits, the Belt Tensioner is often included to ensure that during routine maintenance, the tensioning system is in top condition. This helps in prolonging the life of the belts and the components they drive, such as the alternator and water pump.

Mounting and Pulley Systems

The mounting of the Belt Tensioner is designed to work seamlessly with the pulley systems of the engine. It ensures that the tensioner can adjust automatically to maintain the right tension as the belts wear over time. This integration is essential for the reliable operation of the entire drive system.

Conclusion

In summary, the 3936212 Belt Tensioner is a key component in ensuring that the drive belts in engine systems operate efficiently and reliably. Its role in maintaining proper belt tension is essential for the performance of components like the alternator and water pump, contributing to the overall health and efficiency of the engine.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.