This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

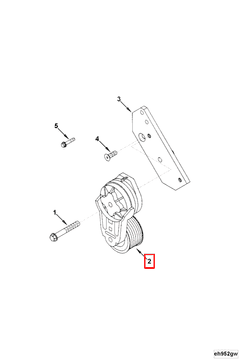

The Cummins 3973822 Belt Tensioner is a component designed for use in commercial trucks. Its purpose is to maintain the correct tension on the drive belts within the engine system. This ensures efficient operation of the truck’s accessory systems, such as the alternator, water pump, and air conditioning compressor. Proper belt tension is significant for the reliable and efficient performance of these systems 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at the correct tension. It functions by applying consistent pressure to the belt, which prevents slippage and ensures that power is effectively transmitted to the accessories. Maintaining proper belt tension is important for the longevity of the belts and the efficient operation of the engine’s accessory systems 2.

Purpose of the Cummins 3973822 Belt Tensioner

The Cummins 3973822 Belt Tensioner plays a role in the operation of a truck by maintaining the correct tension on the drive belts. This ensures that the belts do not slip or become too tight, which can lead to premature wear or failure. By keeping the belts at the optimal tension, the tensioner contributes to the efficient and reliable operation of the truck’s accessory systems 3.

Key Features

The Cummins 3973822 Belt Tensioner is characterized by its robust design and the use of high-quality materials. These features enhance its performance and durability. The tensioner is engineered to withstand the demanding conditions of commercial truck operation, providing consistent belt tension under varying loads and temperatures.

Benefits of Using the Cummins 3973822 Belt Tensioner

The use of the Cummins 3973822 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that the drive belts operate at the correct tension. This reduces wear on the belts and enhances the reliability of the truck’s accessory systems. Additionally, the tensioner’s design and materials contribute to its durability, providing long-term performance in demanding applications 4.

Installation and Compatibility

Proper installation of the Cummins 3973822 Belt Tensioner is important for its effective operation. The tensioner is designed to be compatible with a range of truck models and engine types. Following the manufacturer’s guidelines for installation ensures that the tensioner functions as intended, contributing to the efficient operation of the truck’s accessory systems.

Troubleshooting Common Issues

Common issues associated with belt tensioners include noise, slippage, or premature wear. These problems can often be identified through regular inspection and maintenance. Solutions may involve adjusting the tensioner, replacing worn belts, or addressing other underlying issues within the engine system.

Maintenance Tips

Routine maintenance practices are important for ensuring the longevity and optimal performance of the Cummins 3973822 Belt Tensioner. This includes regular inspection of the tensioner and belts for signs of wear or damage, and following the manufacturer’s guidelines for replacement intervals. Proper maintenance contributes to the efficient and reliable operation of the truck’s accessory systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product offerings include a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles.

Role of Part 3973822 Belt Tensioner in Engine Systems

The Part 3973822 Belt Tensioner is an integral component in maintaining the optimal performance of various engine systems. It ensures that the drive belt remains properly tensioned, which is essential for the efficient operation of connected components.

Interaction with the Drive System

In the drive system, the Belt Tensioner works in conjunction with the drive belt to transfer power from the engine to various peripheral components. Proper tensioning by the Belt Tensioner prevents slippage of the drive belt, ensuring consistent power transmission. This reliability is vital for the smooth operation of the engine and its accessories.

Coordination with the Alternator

The alternator relies on the drive belt to generate electrical power for the vehicle. The Belt Tensioner plays a significant role here by maintaining the correct tension on the belt as it wraps around the alternator pulley. This ensures that the alternator receives a steady rotational force, allowing it to efficiently convert mechanical energy into electrical energy. Without adequate tension, the alternator may not function optimally, leading to potential electrical issues within the vehicle.

Conclusion

The Cummins 3973822 Belt Tensioner is a vital component in the maintenance and operation of commercial truck engine systems. Its role in maintaining proper belt tension ensures the efficient and reliable performance of the truck’s accessory systems. Through proper installation, regular maintenance, and understanding of its function, the Belt Tensioner contributes significantly to the overall performance and longevity of the vehicle.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ -

Cummins Inc. C Command HD Elite™ Panel System. Owners Manual, Bulletin Number 4332829.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.