3976834

Belt Tensioner

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

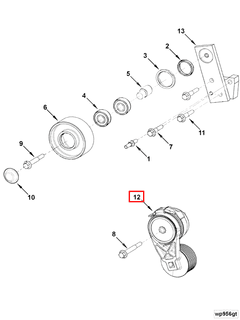

The Cummins 3976834 Belt Tensioner is a component designed to maintain the proper tension on drive belts within commercial truck engines. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as alternators, water pumps, and air conditioning compressors 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep drive belts at the correct tension. It functions by applying consistent pressure to the belt, which prevents slippage and ensures that power is effectively transmitted from the engine to the accessories it drives. Maintaining proper belt tension is important for the longevity of the belts and the overall performance of the engine system 2.

Purpose of the Cummins 3976834 Belt Tensioner

The Cummins 3976834 Belt Tensioner plays a role in the operation of a truck by maintaining the correct tension on drive belts. This ensures that the belts do not slip or become overly tight, which could lead to premature wear or failure. By keeping the belts at the optimal tension, the tensioner contributes to the smooth and reliable operation of engine-driven accessories 3.

Key Features

The Cummins 3976834 Belt Tensioner is constructed with durable materials to withstand the rigors of commercial truck operation. Its design includes a mechanism that automatically adjusts to maintain consistent belt tension, even as belts stretch over time. Unique attributes may include a robust housing and a precision-machined pulley, which work together to provide reliable performance 4.

Benefits of Using the Cummins 3976834 Belt Tensioner

The Cummins 3976834 Belt Tensioner offers several advantages. It contributes to improved belt life by preventing excessive wear from slippage. Enhanced engine performance is another benefit, as properly tensioned belts ensure that accessories receive the necessary power to function efficiently. Additionally, the use of this tensioner can lead to reduced maintenance requirements, as it helps to minimize belt-related issues 5.

Installation Process

Installing the Cummins 3976834 Belt Tensioner involves several steps. First, the old tensioner must be removed, which may require specific tools to release the tension on the belt. Once the old tensioner is out, the new one can be positioned and secured in place. It is important to follow the manufacturer’s instructions carefully to ensure proper installation and function 6.

Troubleshooting Common Issues

Common problems with belt tensioners can include noise from the tensioner pulley, belt squeal, or visible wear on the tensioner components. These issues may be caused by a faulty tensioner, incorrect installation, or normal wear and tear. Solutions or adjustments may involve inspecting the tensioner for damage, ensuring it is properly installed, or replacing it if necessary 7.

Maintenance Tips

Regular maintenance of the Cummins 3976834 Belt Tensioner is important to ensure its continued reliable operation. This includes periodic inspections for signs of wear, such as cracks or excessive play in the pulley. Replacement recommendations may vary based on the manufacturer’s guidelines and the operating conditions of the truck 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, filtration systems, and other components that are integral to the performance and efficiency of commercial vehicles 9.

Belt Tensioner 3976834 Compatibility with Cummins Engines

The Belt Tensioner part number 3976834, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining proper belt tension, ensuring efficient operation and longevity of the engine’s components. Below is a detailed breakdown of the engines with which this belt tensioner is compatible:

B Series Engines

-

B4.5 Series

- B4.5

- B4.5 CM2350 B129B

- B4.5 RGT

-

B5.6 Series

- B5.6 CM2670 B152B

-

B6.7 Series

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

F Series Engines

-

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

-

F4.5 Series

- F4.5 CM2620 F139B

ISB Series Engines

-

ISB4.5 Series

- ISB/ISD4.5 CM2150 B119

- ISB4.5 CM2350 B104

-

ISB5.9 Series

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

-

ISB6.7 Series

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

-

ISB/ISD Series

- ISB/ISD6.7 CM2150 SN

-

ISBE Series

- ISBE CM2150

ISB/ISD Series Engines

-

ISB/ISD4.5 Series

- ISB/ISD4.5 CM2150 B119

-

ISB/ISD6.7 Series

- ISB/ISD6.7 CM2150 SN

This belt tensioner is engineered to ensure compatibility with the specified engines, providing reliable performance and ease of installation. It is essential to verify the correct fitment before installation to ensure optimal engine operation 10.

Role of Part 3976834 Belt Tensioner in Engine Systems

The 3976834 Belt Tensioner is an integral component in maintaining the optimal performance of various engine-driven accessories. It ensures that the drive belt remains properly tensioned, which is essential for the efficient operation of components such as the alternator, fan, and water pump 11.

Interaction with the Alternator Drive

The alternator drive relies on consistent belt tension to generate electricity efficiently. The 3976834 Belt Tensioner adjusts the belt’s tension, compensating for wear and thermal expansion, thereby ensuring that the alternator receives the necessary power to function correctly without slipping or excessive wear 12.

Coordination with the Fan Drive

The fan drive, responsible for cooling the engine, depends on a well-tensioned belt to operate effectively. The 3976834 Belt Tensioner maintains the appropriate tension, allowing the fan to spin at the required speed to dissipate heat, preventing engine overheating 13.

Support for the Water Pump Drive

The water pump drive is vital for circulating coolant through the engine. Proper belt tension, maintained by the 3976834 Belt Tensioner, ensures that the water pump operates smoothly, providing consistent coolant flow to regulate engine temperature and prevent overheating 14.

Overall Belt System Efficiency

In the broader context of the belt-driven system, the 3976834 Belt Tensioner plays a significant role in enhancing the durability and performance of the belt itself. By keeping the belt properly tensioned, it reduces the risk of belt failure, extends the belt’s lifespan, and ensures that all driven components receive the necessary power for optimal operation 15.

Conclusion

The Cummins 3976834 Belt Tensioner is a critical component in the maintenance and operation of commercial truck engines. By ensuring proper belt tension, it contributes to the efficient operation of engine-driven accessories, enhances engine performance, and extends the lifespan of drive belts. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Cummins Inc. General Information. Bulletin Number 3666417, Operation and Maintenance Manual.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Cummins Inc. General Information. Bulletin Number 3666417, Operation and Maintenance Manual.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Cummins Inc. General Information. Bulletin Number 3666417, Operation and Maintenance Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 3666417, Operation and Maintenance Manual.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Cummins Inc. General Information. Bulletin Number 3666417, Operation and Maintenance Manual.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.