This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

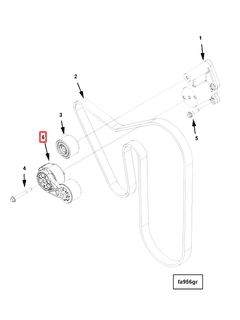

The Cummins 4959902 Belt Tensioner is a component designed for use in commercial trucks, specifically within the engine’s accessory drive system. Its purpose is to maintain the correct tension on the belts that drive various engine accessories, ensuring efficient and reliable operation. The significance of this part lies in its contribution to the overall performance and longevity of the truck’s engine system 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at the proper tension. It functions by automatically adjusting the position of the belt to compensate for wear and changes in temperature, which can cause the belt to stretch or contract. Proper belt tension is important for the efficient transfer of power from the engine to accessories such as the alternator, water pump, and air conditioning compressor. It also helps in reducing wear on both the belts and the accessories they drive 2.

Purpose of the Cummins 4959902 Belt Tensioner

The Cummins 4959902 Belt Tensioner plays a role in the engine’s accessory drive system by ensuring that the belts remain under the correct amount of tension. This is vital for the efficient operation of engine accessories, which rely on a consistent and optimal level of tension to function correctly. By maintaining proper belt tension, the tensioner contributes to the smooth and reliable operation of the truck’s engine system 3.

Key Features

The Cummins 4959902 Belt Tensioner is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. Its design allows for automatic adjustment of belt tension, accommodating changes in belt length due to wear or environmental conditions. The materials used in its construction are chosen for their strength and resistance to wear, ensuring long-term reliability in demanding commercial truck applications.

Benefits of Using the Cummins 4959902 Belt Tensioner

Utilizing the Cummins 4959902 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that the drive belts operate under optimal tension, which reduces the risk of slippage and enhances the transfer of power to engine accessories. This, in turn, leads to reduced wear on both the belts and the accessories they drive, promoting longer service intervals and lower maintenance costs. Additionally, the tensioner’s design and construction enhance the reliability of the engine’s accessory drive system, contributing to the overall performance and durability of the truck.

Installation and Compatibility

Proper installation of the Cummins 4959902 Belt Tensioner is important for ensuring its effective operation and the reliability of the engine’s accessory drive system. Installation guidelines should be followed to ensure that the tensioner is correctly positioned and secured, and that the belts are properly tensioned. Specific requirements or considerations may vary depending on the truck model, so it is important to consult the manufacturer’s instructions or a professional technician for guidance on installation.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the optimal performance and longevity of the Cummins 4959902 Belt Tensioner. Common issues may include belt slippage, unusual noises, or signs of wear on the tensioner or belts. Routine inspections and adjustments can help identify and address these issues before they lead to more significant problems. Following the manufacturer’s recommended maintenance schedule and guidelines can help ensure the tensioner continues to operate effectively, contributing to the reliable performance of the truck’s engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a reputation for quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 4959902 Belt Tensioner, which is designed to meet the demanding requirements of commercial truck applications.

Belt Tensioner 4959902 Compatibility with Cummins Engines

The Belt Tensioner part number 4959902, manufactured by Cummins, is designed to fit a variety of engine models. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and associated components.

ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101

The Belt Tensioner 4959902 is compatible with the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101 engines. These engines are part of the Cummins lineup and are known for their robust performance and reliability. The tensioner ensures that the belt remains taut, preventing slippage and maintaining the necessary power transfer to the engine’s accessories.

QSZ13 CM2150 Z102

Similarly, the QSZ13 CM2150 Z102 engine also requires the Belt Tensioner 4959902. This engine shares many characteristics with the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101, making the tensioner a direct fit. It is essential for maintaining the correct belt tension, which is critical for the efficient operation of the engine’s ancillary systems.

Z13 Z108G

The Z13 Z108G engine is another model that is compatible with the Belt Tensioner 4959902. This engine is part of the Cummins family and benefits from the precise tensioning provided by this part. Ensuring the belt is correctly tensioned helps in reducing wear and tear on the belt and the pulleys, thereby extending the life of these components.

By using the Belt Tensioner 4959902, operators of these engines can maintain optimal performance and reliability, ensuring that their engines run smoothly and efficiently.

Role of Part 4959902 Belt Tensioner in Engine Systems

The 4959902 Belt Tensioner is an essential component in maintaining the optimal performance of various engine systems. It ensures that the belt remains properly tensioned, which is vital for the efficient operation of connected components.

Interaction with the Belt

The Belt Tensioner, part 4959902, works in conjunction with the belt to maintain consistent tension. This is important because a properly tensioned belt ensures smooth and efficient power transmission to other engine components. Without adequate tension, the belt may slip, leading to inefficient operation and potential damage to the belt and connected parts.

Coordination with the Fan Drive

In systems where the fan drive is present, the Belt Tensioner plays a significant role. The fan drive relies on the belt to transfer power from the engine to the fan, which helps in cooling the engine by drawing air through the radiator. The Belt Tensioner ensures that the belt remains taut, allowing the fan drive to operate effectively and maintain the engine’s temperature within safe limits.

Integration with the Mounting System

The mounting of the Belt Tensioner is designed to provide stability and adjustability. Proper mounting ensures that the tensioner can move freely to accommodate the varying loads and movements of the belt. This flexibility is essential for maintaining consistent tension across different engine operating conditions.

Ensuring Smooth Operation of the Fan Drive

The fan drive, which is often mounted on the engine, requires a steady and reliable power source to function correctly. The Belt Tensioner ensures that the belt driving the fan drive remains under the correct tension, allowing the fan to spin at the required speed to provide adequate cooling. This integration is vital for the overall efficiency and longevity of the engine system.

Conclusion

In summary, the 4959902 Belt Tensioner is a key component in ensuring that the belt, fan drive, and mounting system work together seamlessly. Its role in maintaining proper belt tension is fundamental to the efficient and reliable operation of the engine.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.