This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

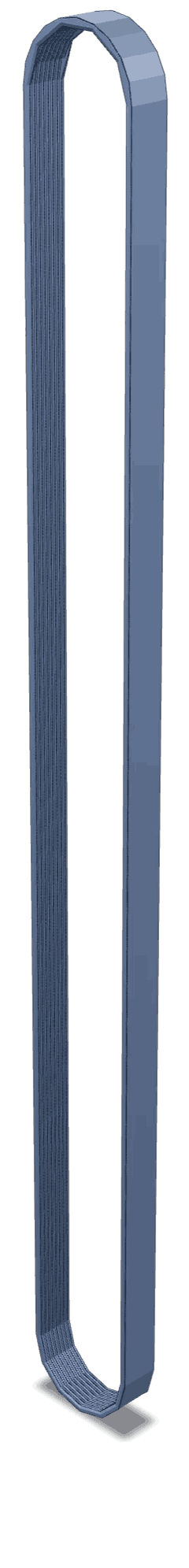

The Cummins V Ribbed Belt (Part #3288878) is a component designed for use in heavy-duty truck operations. Its purpose is to transmit power from the engine to various accessories, ensuring they operate efficiently. The significance of this belt in heavy-duty truck operations lies in its ability to support the functionality of engine accessories, contributing to the overall performance and reliability of the vehicle 2.

Basic Concepts of V Ribbed Belts

V Ribbed Belts are characterized by their trapezoidal cross-section, which allows them to fit into corresponding grooves on pulleys. This design enhances their grip and reduces the likelihood of slippage. In mechanical systems, these belts play a role in transmitting power from a prime mover to various components, facilitating the operation of accessories such as alternators, water pumps, and air conditioning compressors 3.

Role of the Cummins V Ribbed Belt in Truck Operation

In the operation of heavy-duty trucks, the Cummins V Ribbed Belt plays a role by driving various engine accessories. It ensures that these components receive the necessary power to function correctly. By maintaining the operation of accessories like the alternator and water pump, the belt contributes to the truck’s electrical system and engine cooling, respectively 1.

Key Features of the Cummins V Ribbed Belt

The Cummins V Ribbed Belt is distinguished by its material composition, which typically includes high-strength materials to withstand the rigors of heavy-duty applications. Its design incorporates multiple ribs, which increase the contact surface area with pulleys, enhancing power transmission efficiency. Engineering specifications such as belt length, width, and rib configuration are tailored to meet the demands of specific truck models, ensuring optimal performance and durability 4.

Benefits of Using the Cummins V Ribbed Belt

Utilizing the Cummins V Ribbed Belt offers several advantages. It provides improved efficiency in power transmission, reducing the load on the engine. Additionally, its design and material composition contribute to reduced maintenance requirements, as it is engineered to withstand harsh operating conditions. Enhanced reliability is another benefit, as the belt is designed to maintain performance over extended periods, supporting the longevity of the truck’s engine accessories 3.

Installation and Maintenance Guidelines

Proper installation of the Cummins V Ribbed Belt is crucial for ensuring optimal performance and longevity. It should be installed with the correct tension to prevent slippage and ensure efficient power transmission. Routine maintenance practices include regular inspections for signs of wear, proper tension adjustment, and replacement according to the manufacturer’s recommendations or when signs of degradation are observed 1.

Troubleshooting Common Issues

Common problems associated with V Ribbed Belts include slippage, wear, and noise. Slippage can often be addressed by adjusting the belt tension or inspecting for pulley misalignment. Wear may necessitate belt replacement, while noise could indicate a need for lubrication or further investigation into the belt’s condition or the pulleys it engages with 3.

Performance Enhancements

The Cummins V Ribbed Belt contributes to overall engine performance by ensuring that engine accessories operate efficiently. This efficiency can lead to improved fuel economy, as the engine does not need to work harder to power these accessories. Additionally, the reliability of the belt supports the truck’s operational reliability, reducing downtime and maintenance costs 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various applications 4.

V Ribbed Belt 3288878 Compatibility with Cummins Engines

The V Ribbed Belt part number 3288878, manufactured by Cummins, is designed to fit a variety of Cummins engines. This belt is crucial for the proper functioning of engine accessories such as the alternator, water pump, and air conditioning compressor. Below is a detailed overview of the engines with which this belt is compatible.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- ISB CM550

- ISC CM554

- ISC CM850

- ISL CM554

- ISL9 CM2150 SN

- QSB5.9 44 CM550

- QSC8.3 CM554

- QSL9 CM554

Grouping of Compatible Engines

Group 1: B Series Engines

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

Group 2: ISB, ISC, ISL Series Engines

- ISB CM550

- ISC CM554

- ISC CM850

- ISL CM554

- ISL9 CM2150 SN

Group 3: QSB, QSC, QSL Series Engines

- QSB5.9 44 CM550

- QSC8.3 CM554

- QSL9 CM554

Other Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

Each of these engines relies on the V Ribbed Belt 3288878 for the efficient transfer of power to various engine accessories, ensuring optimal performance and reliability 4.

Understanding the Role of Part 3288878 V Ribbed Belt in Engine Systems

The V ribbed belt, specifically part 3288878, is a component in the efficient operation of various engine systems. Its primary function is to transmit power from the engine’s crankshaft to multiple peripheral components, ensuring they operate in sync with the engine’s rotational speed 3.

Integration with the Alternator Drive

In the alternator drive system, the V ribbed belt part 3288878 is responsible for driving the alternator. As the belt engages with the alternator’s pulley, it spins the alternator, which in turn generates electrical power to charge the battery and power the vehicle’s electrical systems. This seamless transfer of mechanical energy to electrical energy is fundamental for maintaining the vehicle’s electrical supply 1.

Role in the Engine Installation Kit

When installing a new engine, the V ribbed belt part 3288878 is a key element in the engine installation kit. It ensures that all driven components are correctly aligned and tensioned. Proper installation of the belt is vital for the balanced operation of the engine, preventing slippage and ensuring consistent power transmission to components like the alternator and water pump 3.

Importance in the Kit Service Parts

As part of the kit service parts, the V ribbed belt part 3288878 plays a significant role in maintaining the engine’s performance over time. Regular replacement of the belt as part of scheduled maintenance helps prevent unexpected failures, such as belt breakage, which can lead to component malfunction and potential engine damage 1.

Function in the Water Pump Drive

The water pump drive system relies on the V ribbed belt part 3288878 to circulate coolant through the engine. By driving the water pump, the belt ensures that coolant is continuously pumped through the engine block and cylinder head, dissipating heat and maintaining optimal engine temperature. This is essential for preventing overheating and ensuring the engine operates within its designed temperature range 2.

Interaction with the Water Pump Drive Pulley

The V ribbed belt part 3288878 engages with the water pump drive pulley to transfer power from the crankshaft to the water pump. This interaction is critical for the efficient operation of the cooling system. The belt’s ribbed design enhances grip and reduces slippage, ensuring reliable power transmission even under varying engine loads and speeds 3.

Conclusion

In summary, the V ribbed belt part 3288878 is integral to the operation of several engine systems, including the alternator drive, engine installation kit, kit service parts, water pump drive, and water pump drive pulley. Its reliable performance ensures the smooth and efficient operation of these components, contributing to the overall functionality and longevity of the engine 4.

-

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ ↩ ↩ ↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ ↩ ↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩ ↩ ↩ ↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.