This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

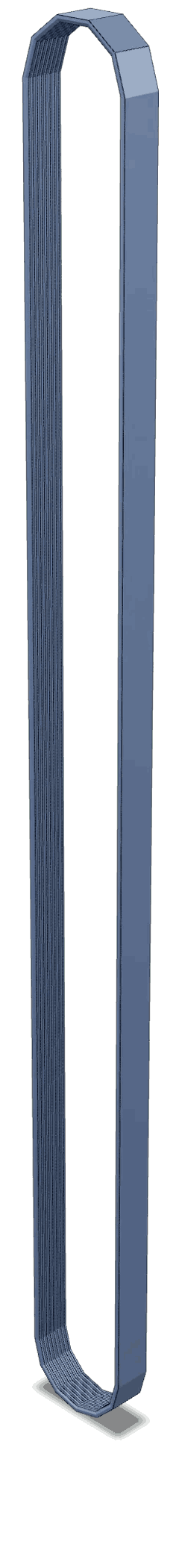

The 4938205 V-Ribbed Serpentine Belt is a component manufactured by Cummins, a well-established name in the automotive industry. This belt is specifically designed for use in commercial trucks, where it plays a significant role in the efficient operation of the engine system. Cummins is renowned for its commitment to quality and durability in automotive components, and the 4938205 V-Ribbed Serpentine Belt is no exception.

Basic Concepts of V-Ribbed Serpentine Belts

A V-Ribbed Serpentine Belt is a type of belt used in modern engines to drive multiple peripheral devices such as the alternator, water pump, and air conditioning compressor. Unlike older multi-V-belt systems, which use several individual belts, the serpentine belt uses a single, continuous belt with multiple ribs that contact the pulleys. This design allows for a more compact engine layout and reduces the likelihood of belt misalignment. The belt’s construction typically includes a durable rubber compound with embedded textile cords for strength and flexibility 1.

Operational Role of the 4938205 V-Ribbed Serpentine Belt

In the operation of a truck, the 4938205 V-Ribbed Serpentine Belt drives several key components. These include the alternator for charging the battery, the water pump for cooling the engine, and often the air conditioning compressor and power steering pump. By ensuring these components receive the necessary power, the belt plays a role in maintaining engine efficiency and overall vehicle performance. Its proper function is vital for the reliable operation of the truck 2.

Key Features

The 4938205 V-Ribbed Serpentine Belt features several notable characteristics. It is constructed from high-quality materials that offer enhanced durability and resistance to wear. The belt’s design includes multiple ribs that provide a larger contact area with the pulleys, improving grip and reducing slippage. Additionally, the materials used are chosen for their ability to withstand the high temperatures and dynamic loads encountered in commercial truck engines 3.

Benefits of Using the 4938205 V-Ribbed Serpentine Belt

Utilizing the 4938205 V-Ribbed Serpentine Belt in a truck’s engine system offers several advantages. The belt’s robust construction and design contribute to improved performance and reliability. Its efficient power transmission helps maintain engine efficiency, potentially leading to better fuel economy. Furthermore, the belt’s durability reduces the frequency of replacements, offering long-term value to the vehicle owner.

Installation Process

Installing the 4938205 V-Ribbed Serpentine Belt requires careful attention to ensure proper fit and function. The process involves relieving tension on the belt using a tensioner tool, removing the old belt, and routing the new belt according to the manufacturer’s specifications. It is important to ensure the belt is correctly aligned with all pulleys to prevent damage and ensure optimal performance. Tools such as a socket wrench and tensioner tool may be needed for the installation.

Troubleshooting Common Issues

Common problems with V-Ribbed Serpentine Belts include squealing noise, visible wear or cracking, and failure to drive components effectively. Squealing can often be addressed by checking the belt tension and alignment. Wear or cracking may indicate the need for replacement. If components are not being driven effectively, it could be due to a loose belt, misaligned pulleys, or a faulty tensioner.

Maintenance Tips

To ensure the longevity and optimal performance of the 4938205 V-Ribbed Serpentine Belt, regular maintenance is recommended. This includes periodic inspections for signs of wear, proper tension adjustment, and keeping the belt clean and free from contaminants. Following the manufacturer’s maintenance schedule can help prevent unexpected failures and extend the belt’s service life.

Signs of Wear and Replacement Guidelines

Signs that the 4938205 V-Ribbed Serpentine Belt may need replacement include visible cracks, glazing, or fraying of the belt edges. Additionally, if the belt begins to squeal or shows signs of slippage, it may be time for a replacement. Cummins recommends replacing the belt according to the vehicle’s maintenance schedule or when signs of wear are observed to prevent component failure and ensure engine efficiency.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the automotive industry, known for its high-quality engines and components. With a history spanning over a century, Cummins has built a reputation for innovation, reliability, and commitment to customer satisfaction. Their products, including the 4938205 V-Ribbed Serpentine Belt, are designed with a focus on durability, performance, and compatibility with a wide range of commercial vehicles.

V-Ribbed Serpentine Belt (Part 4938205) Compatibility with Cummins Engines

The V-Ribbed Serpentine Belt, identified by part number 4938205, is a critical component in the engine’s accessory drive system. This belt is designed to efficiently transfer power from the engine’s crankshaft to various engine accessories such as the alternator, power steering pump, and air conditioning compressor.

ISB and ISBE Series

- ISB CM2150

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The V-Ribbed Serpentine Belt 4938205 is compatible with the ISB and ISBE series engines. These engines are known for their robust design and are often used in heavy-duty applications. The belt’s design ensures it can handle the high torque and rotational speeds typical of these engines, providing reliable power transfer to the engine accessories.

ISC and ISL Series

- ISC8.3 CM2250

- ISL9 CM2250

The ISC and ISL series engines also benefit from the V-Ribbed Serpentine Belt 4938205. These engines are designed for medium-duty applications and are known for their efficiency and durability. The belt’s ribbed design provides a secure grip on the pulleys, reducing the risk of slippage and ensuring consistent performance.

QSB and QSL Series

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSL9 CM2250

- QSL9 CM2350 L102

The QSB and QSL series engines are typically used in agricultural and industrial applications. The V-Ribbed Serpentine Belt 4938205 is engineered to fit these engines seamlessly, ensuring efficient power transfer to the engine accessories. The belt’s durability and resistance to wear make it an ideal choice for the demanding conditions these engines often encounter.

Summary

The V-Ribbed Serpentine Belt 4938205 is a versatile and reliable component that fits a wide range of Cummins engines. Whether used in heavy-duty, medium-duty, or industrial applications, this belt ensures efficient power transfer and consistent performance across various engine series.

Role of Part 4938205 V-Ribbed Serpentine Belt in Engine Systems

The V-Ribbed Serpentine Belt, identified by part number 4938205, is integral to the efficient operation of several key engine components. This belt operates on a single, continuous loop, transferring mechanical power from the engine’s crankshaft to various auxiliary components.

Power Transmission to Auxiliary Components

-

Water Pump: The serpentine belt drives the water pump, which circulates coolant through the engine to maintain optimal operating temperatures. This circulation prevents overheating and ensures the engine operates within its designed thermal parameters.

-

Front Drive: In systems where a front drive is utilized, the serpentine belt provides the necessary power to this component. The front drive can be part of various systems, including the alternator or air conditioning compressor, depending on the vehicle’s configuration.

-

Alternator Drive: The belt is responsible for driving the alternator, which generates electrical power to charge the battery and power the vehicle’s electrical systems. Consistent and reliable operation of the alternator is essential for maintaining the vehicle’s electrical supply.

-

Air Conditioning Compressor Drive: In vehicles equipped with air conditioning, the serpentine belt drives the compressor. This component pressurizes the refrigerant, enabling the air conditioning system to cool the interior of the vehicle effectively.

-

Power Steering Pump Drive: The belt also powers the power steering pump, which assists in steering by providing hydraulic pressure to the steering mechanism. This makes steering the vehicle easier and more responsive.

Integration and Functionality

The V-Ribbed design of the serpentine belt allows it to engage multiple pulleys simultaneously, each connected to a different auxiliary component. This design enhances efficiency by reducing the number of belts required and minimizing the complexity of the engine’s accessory drive system.

The belt’s ribbed surface increases the contact area with the pulleys, improving grip and reducing the likelihood of slippage. This ensures consistent power transmission to all connected components, maintaining their reliable operation.

Conclusion

In summary, the 4938205 V-Ribbed Serpentine Belt plays a significant role in the coordinated function of the water pump, front drive, alternator, air conditioning compressor, and power steering pump. Its design and placement are essential for the seamless operation of these critical engine systems.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.