This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3020859 Tube Brace, a component manufactured by Cummins, is integral to the structural integrity and performance of heavy-duty trucks. Cummins, a renowned name in the automotive and heavy-duty truck industry, produces this part to enhance the durability and efficiency of trucks.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle frameworks to enhance rigidity and distribute loads more effectively. They contribute to the overall integrity and performance of a truck by reinforcing critical areas of the chassis, helping withstand operational stresses and strains 1.

Purpose of the 3020859 Tube Brace

The 3020859 Tube Brace is designed to enhance the structural integrity and performance of heavy-duty trucks. It reinforces specific areas of the truck’s chassis, aiding in the even distribution of loads and reducing stress on critical components. This reinforcement can lead to improved durability and performance, enabling the truck to handle heavier loads and operate under more demanding conditions 2.

Key Features

This Cummins part is constructed using high-quality materials, ensuring durability and reliability. Its design includes precise dimensions tailored to fit specific areas of the truck’s chassis. Unique characteristics of this tube brace may include its robust construction and the use of advanced materials, which set it apart from other tube braces in terms of performance and longevity 3.

Benefits

Utilizing the 3020859 Tube Brace offers several advantages. It contributes to improved structural rigidity, enhancing the overall safety of the truck. Additionally, by reinforcing the chassis, it may allow for increases in payload capacity, making the truck more versatile for various applications. The brace also plays a role in extending the lifespan of the truck by reducing wear and tear on critical components.

Installation Considerations

When installing the 3020859 Tube Brace, it is important to follow guidelines and best practices to ensure proper fitment and functionality. Preparatory steps may include cleaning the installation area and ensuring the chassis is free from any debris or corrosion. The use of appropriate tools is necessary for a secure and accurate installation. Alignment considerations are crucial to ensure the brace effectively reinforces the intended areas of the chassis.

Troubleshooting and Maintenance

Common issues with tube braces may include misalignment, corrosion, or physical damage. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Maintenance tips for the 3020859 Tube Brace include keeping it clean and free from corrosion, and ensuring it remains securely fastened to the chassis. These practices help ensure the longevity and effectiveness of the brace.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Their product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of vehicles.

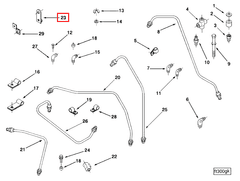

Role of Part 3020859 Tube Brace in Engine Systems

The 3020859 Tube Brace is an integral component in the structural integrity and efficient operation of various engine systems. Its primary function is to provide support and stability to critical fuel and air supply lines, ensuring that these systems operate under optimal conditions.

Fuel System Integration

In the fuel system, the 3020859 Tube Brace supports the Fuel Supply Tube and Fuel Supply Tubing. This brace ensures that the fuel lines remain securely in place, minimizing the risk of fuel leaks and maintaining consistent fuel pressure. It also supports the Injector Fuel Supply Tube, which is vital for precise fuel delivery to the engine’s injectors.

Additionally, the brace is connected to the Fuel Pump and Fuel Supply Mounting Tube, providing necessary support to these components. This ensures that the fuel pump can operate efficiently without undue stress on its mounting points.

Air and Turbocharger Systems

For the air supply and turbocharger systems, the 3020859 Tube Brace plays a significant role in supporting the Manifold Pressure Mounting Tube and MFLD Pres Tube. These tubes are responsible for delivering pressurized air to the engine’s intake manifold, and the brace ensures that they remain aligned and secure.

The brace also interfaces with the Turbocharger Mounting system. By providing additional support to the turbocharger’s air intake and exhaust tubes, it helps maintain the turbocharger’s alignment and operational efficiency.

Cold Start and Aftercooler Systems

In cold start systems, the 3020859 Tube Brace supports the Cold Start Mounting Pump and associated tubing. This ensures that the pump can deliver fuel effectively during startup, especially in cold conditions where fuel viscosity is higher.

Furthermore, the brace is integral to the Aftercooler Drain Mounting system. It supports the tubes and fittings that drain condensate from the aftercooler, ensuring that the aftercooler operates efficiently and that the drained condensate is properly managed.

Plumbing and Assembly

The 3020859 Tube Brace is also essential in the overall Plumbing of the engine, particularly in the fuel and air supply lines. It supports the Assembly Step Control components, ensuring that each step in the fuel and air delivery process is securely mounted and aligned.

Conclusion

In summary, the 3020859 Tube Brace is a versatile component that enhances the reliability and performance of various engine systems by providing necessary support and stability to critical fuel and air supply lines.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Van Gelder, K.T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.