This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Brace 3093291, manufactured by Cummins, is a component designed for heavy-duty truck applications. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance parts. This part is significant in enhancing the structural integrity and operational efficiency of heavy-duty trucks.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle frameworks to provide additional support and stability. They function by reinforcing the chassis and other critical areas, thereby contributing to the overall integrity of the vehicle. These braces help in distributing loads more evenly across the vehicle’s frame, reducing stress on individual components and enhancing durability 1.

Purpose of Tube Brace 3093291

The Tube Brace 3093291 plays a specific role in the operation and structural integrity of heavy-duty trucks. It is designed to reinforce the frame, particularly in areas subjected to high stress and load. By providing additional support, this tube brace helps in maintaining the alignment and stability of the truck’s frame, which is crucial for safe and efficient operation.

Key Features

The Tube Brace 3093291 boasts several key features that make it an effective component for heavy-duty applications. It is constructed from high-strength steel, ensuring durability and resistance to wear and tear. The design includes precise welding and a robust structure to handle significant loads. Additionally, the tube brace is engineered to fit seamlessly with Cummins engines and other compatible truck models, ensuring easy installation and integration.

Benefits

The advantages of using the Tube Brace 3093291 include enhanced durability, improved load distribution, and increased safety. By reinforcing the truck’s frame, this component helps in prolonging the vehicle’s lifespan and reducing the risk of structural failure. It also contributes to better load distribution, which is vital for trucks that carry heavy payloads. Furthermore, the added stability provided by the tube brace enhances overall safety during operation 2.

Installation Process

Installing the Tube Brace 3093291 involves several steps to ensure proper fitting and functionality. Begin by identifying the correct location on the truck’s frame where the brace will be installed. Use the appropriate tools, such as a wrench and drill, to secure the brace in place. Ensure that all connections are tight and that the brace is aligned correctly with the frame. It may be necessary to use additional components, such as brackets or spacers, to achieve a perfect fit.

Troubleshooting Common Issues

Common problems associated with tube braces include misalignment, loose connections, and damage from corrosion. To address these issues, regularly inspect the brace for any signs of wear or damage. Tighten any loose connections and realign the brace if necessary. In cases of corrosion, clean the affected areas and apply a protective coating to prevent further damage.

Maintenance Tips

To ensure the longevity and effectiveness of the Tube Brace 3093291, regular maintenance is recommended. Inspect the brace periodically for any signs of wear, damage, or corrosion. Clean the component and its connections to remove dirt and debris that could cause issues. Additionally, ensure that all bolts and connections are tight and secure. Applying a protective coating can also help in preventing corrosion and extending the life of the tube brace.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for producing high-quality, reliable components for various industries, including automotive and heavy-duty trucking. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of modern applications 3.

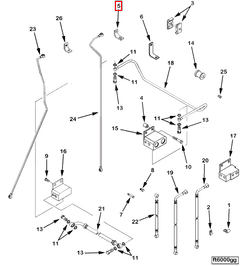

Role of Part 3093291 Tube Brace in Plumbing and Fuel Systems

The Tube Brace 3093291 is instrumental in maintaining the structural integrity and efficient operation of both plumbing and fuel systems within various engine setups.

In plumbing systems, the Tube Brace provides essential support to pipes, ensuring they remain securely in place under operational pressures. This support is particularly important in areas where pipes are subject to vibrations or movement, such as near pumps or in sections with frequent fluid flow changes. By stabilizing the pipes, the Tube Brace helps prevent leaks, reduces the risk of pipe fatigue, and ensures consistent fluid delivery throughout the system.

In fuel systems, the Tube Brace plays a similarly significant role. It supports fuel lines, which are often under higher pressure and subject to more dynamic conditions compared to plumbing systems. The brace helps maintain the alignment of fuel lines, which is vital for preventing fuel leaks and ensuring a steady supply of fuel to the engine. This is especially important in high-performance engines where fuel delivery precision can directly impact engine performance and efficiency.

Overall, the integration of the Tube Brace in these systems enhances reliability, safety, and performance, making it a valuable component in the maintenance and operation of engine systems.

Conclusion

The Tube Brace 3093291 by Cummins is a vital component for heavy-duty trucks, offering enhanced structural integrity, improved load distribution, and increased safety. Its robust design and precise engineering ensure durability and seamless integration with Cummins engines. Regular maintenance and proper installation are key to maximizing its benefits and ensuring the longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.