This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

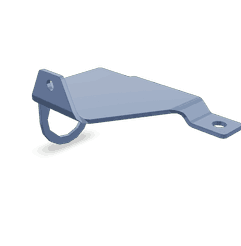

The Cummins 3096813 Wiring Brace is a component designed to support and organize the electrical wiring harnesses in commercial trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system. By securing the wiring harnesses, it helps prevent damage and ensures reliable electrical connections throughout the vehicle 1.

Purpose and Function

The 3096813 Wiring Brace serves to organize and secure the wiring harnesses within the truck’s electrical system. It plays a role in maintaining the structural integrity of the wiring, protecting it from physical damage, and ensuring that electrical connections remain secure and reliable. This organization helps in reducing the risk of electrical faults and enhances the overall performance of the truck’s electrical system 2.

Key Features

The design and construction of the 3096813 Wiring Brace incorporate several features that enhance its performance. It is typically made from durable materials that can withstand the harsh conditions often encountered in commercial trucking. The brace offers various mounting options, allowing for flexible installation in different truck models. Its design ensures that wiring harnesses are held securely in place, reducing the likelihood of wear and tear on the wires 3.

Benefits

The advantages provided by the 3096813 Wiring Brace include improved wire management, which leads to a more organized and efficient electrical system. By securing the wiring harnesses, it reduces the risk of electrical faults that can arise from loose or damaged wires. Additionally, its durable construction ensures longevity and reliability, even in demanding operating conditions.

Installation Process

Proper installation of the 3096813 Wiring Brace involves several steps to ensure optimal performance. It is important to use the appropriate tools and equipment for the task. The installation process typically includes securing the brace in the designated location, attaching the wiring harnesses, and ensuring all connections are tight and secure. Following manufacturer guidelines during installation is recommended to achieve the best results.

Maintenance and Troubleshooting

Regular maintenance of the 3096813 Wiring Brace is important to ensure its continued effectiveness. This includes inspecting the brace and wiring harnesses for signs of wear or damage, and addressing any issues promptly. Common problems may include loose connections or damaged wires, which can be identified through routine checks. Troubleshooting steps may involve tightening connections or replacing damaged components as necessary.

Safety Considerations

When working with the 3096813 Wiring Brace, it is important to follow safety precautions and best practices. This includes ensuring that the electrical system is de-energized before beginning any work to prevent electrical shocks. Proper handling of the brace and wiring harnesses is also crucial to avoid injury or damage. Adhering to industry safety standards and guidelines is recommended to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration, and power generation equipment. The company has a reputation for quality and reliability, with a history of innovation and commitment to customer satisfaction. Cummins products are designed to meet the demanding requirements of commercial trucking, providing efficient and durable solutions for various applications.

Wiring Brace 3096813 Compatibility with Cummins Engines

The Wiring Brace part number 3096813, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is essential for securing and organizing wiring within the engine compartment, ensuring that electrical connections remain stable and protected.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines benefit from the use of the Wiring Brace 3096813. This part helps maintain the integrity of the wiring harness, preventing chafing and damage that can occur due to engine vibrations and movements. By keeping the wiring organized and secured, the Wiring Brace contributes to the overall reliability and longevity of the engine’s electrical system.

ISM CM876

Similarly, the ISM CM876 engine also utilizes the Wiring Brace 3096813. This part is crucial for managing the complex wiring configurations found in this engine model, ensuring that all electrical components function correctly without interference from loose or damaged wiring.

M11 CELECT PLUS

The M11 CELECT PLUS engine is another model that integrates the Wiring Brace 3096813 effectively. Given the advanced electronic systems in this engine, the Wiring Brace plays a vital role in maintaining the structural integrity of the wiring, which is essential for the proper functioning of the engine’s electronic control unit (ECU) and other related systems.

QSM11 CM570

Lastly, the QSM11 CM570 engine also incorporates the Wiring Brace 3096813. This part ensures that the wiring remains neatly arranged and protected, which is particularly important in the demanding environments where this engine is often used. Proper wiring management is key to preventing electrical faults and ensuring consistent engine performance.

Role of Part 3096813 Wiring Brace in Engine Systems

The 3096813 Wiring Brace is an essential component in maintaining the integrity and functionality of various wiring systems within engine assemblies. It provides structural support and organization for multiple wiring harnesses and electronic control modules, ensuring reliable operation and longevity of the engine system.

Integration with Accessories Wiring

In engine systems, the accessories wiring often includes connections for components such as alternators, fuel pumps, and sensors. The 3096813 Wiring Brace secures these wires, reducing the risk of chafing or disconnection, which can lead to intermittent operation or complete failure of these accessories.

Support for Main Wiring Harness

The main wiring harness is a complex network that routes power and signals throughout the engine. The Wiring Brace plays a significant role in keeping this harness organized and protected from physical damage. By securing the harness in place, it prevents wires from coming into contact with moving parts or sharp edges within the engine compartment.

Electronic Control Module (ECM) Wiring

Modern engines rely heavily on electronic control modules to manage fuel injection, ignition timing, and emissions control. The ECM wiring must be meticulously managed to ensure consistent performance. The 3096813 Wiring Brace helps maintain the precise routing of these sensitive wires, safeguarding them against environmental factors and mechanical stress.

Engine Control Wiring Harness

The engine control wiring harness is responsible for connecting the ECM to various sensors and actuators throughout the engine. This harness requires careful management to avoid signal interference and ensure accurate data transmission. The Wiring Brace contributes to this by providing a stable and secure mounting point for the harness.

Engine Count Wiring

In applications where multiple engines are used, such as in marine or industrial settings, engine count wiring is employed to synchronize operations and monitor performance. The 3096813 Wiring Brace assists in organizing these additional wires, ensuring they do not interfere with the primary engine wiring and maintaining clear and efficient communication between engines.

Conclusion

The 3096813 Wiring Brace is a vital component in the maintenance and performance of engine wiring systems, offering both structural support and organizational benefits. Its compatibility with various Cummins engines underscores its importance in ensuring reliable and efficient electrical systems in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.