This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

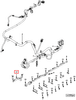

The Cummins 3335571 Wiring Brace is a component designed to support and organize the wiring harnesses in commercial trucks. Its role is to maintain the integrity and efficiency of the truck’s electrical system by securing and routing wires appropriately. This ensures that the electrical connections remain stable and protected from potential damage during operation 1.

Purpose and Function

The primary purpose of the Wiring Brace in a truck’s electrical system is to provide structural support and organization for the wiring harnesses. By securing the wires in place, it prevents them from moving excessively, which could lead to wear, chafing, or disconnection. This organization helps maintain the efficiency of the electrical system, ensuring that all components receive the necessary power without interruption. Additionally, the brace helps protect the wires from physical damage caused by vibrations or contact with other parts of the vehicle 2.

Key Features

The Cummins 3335571 Wiring Brace is engineered with several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear, ensuring longevity in demanding environments. The design of the brace allows for easy installation and integration with existing wiring systems. It features multiple mounting points and adjustable sections to accommodate various wire sizes and configurations, providing a customizable fit for different truck models 3.

Benefits

The installation of the Wiring Brace offers several benefits to the truck’s electrical system. Improved wire management reduces the risk of electrical faults that can arise from loose or damaged wires. This leads to enhanced overall reliability of the electrical system, minimizing the likelihood of unexpected downtime due to electrical issues. Additionally, the organized wiring facilitated by the brace simplifies future maintenance and troubleshooting, as wires are easier to access and inspect.

Installation and Compatibility

Proper installation of the Wiring Brace is crucial for its effective function. It should be securely fastened to the truck’s chassis or frame, ensuring that it does not move during operation. Specific requirements may vary depending on the truck model and engine type, so it is important to follow the manufacturer’s guidelines for installation. Compatibility with different truck models and engine types should be verified to ensure optimal performance and integration with the existing electrical system.

Maintenance and Troubleshooting

To ensure the optimal performance of the Wiring Brace, regular maintenance is recommended. This includes inspecting the brace and wiring for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent further deterioration or electrical faults. Common problems may include loose connections or damaged wires, which can often be resolved by tightening connections or replacing affected sections. Regular checks and maintenance can help identify potential issues before they lead to more significant problems.

Safety Considerations

When working with the Wiring Brace and the truck’s electrical system, it is important to observe several safety guidelines and precautions. Always ensure that the truck’s battery is disconnected before beginning any work on the electrical system to prevent the risk of electric shock. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, to protect against potential hazards. Be mindful of the potential for sharp edges or hot components near the wiring, and take care to avoid contact with moving parts during operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. The company’s commitment to innovation and quality has made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Role of Part 3335571 Wiring Brace in Engine Systems

The 3335571 Wiring Brace is an integral component in the structural integrity and efficient operation of various engine systems. It plays a significant role in supporting and organizing the wiring harnesses and electronic control module (ECM) wiring, ensuring that these components are securely positioned and protected from potential damage.

Harness Support

The wiring brace provides essential support to the wiring harnesses, which are responsible for transmitting electrical signals and power throughout the engine system. By securing the harnesses in place, the brace helps prevent chafing, abrasion, and other forms of wear that could lead to electrical faults or failures. This support is particularly important in high-vibration environments typical of engine compartments.

Electronic Control Module Wiring

For the electronic control module (ECM) wiring, the 3335571 Wiring Brace ensures that the connections remain stable and reliable. The ECM is a central component in modern engine management systems, controlling various functions such as fuel injection, ignition timing, and emissions control. Secure wiring is vital to maintain the precision and responsiveness of the ECM, thereby ensuring optimal engine performance and efficiency.

Engine Control Wiring

In addition to supporting the ECM wiring, the brace also plays a role in managing the engine control wiring. This includes wires that connect to sensors, actuators, and other control components within the engine system. By keeping these wires organized and protected, the brace helps maintain the integrity of the engine’s control signals, which are essential for accurate monitoring and adjustment of engine operations.

Module Integration

The wiring brace facilitates the integration of various modules within the engine system. These modules may include fuel management systems, ignition control units, and emissions monitoring devices. Proper support and organization of the wiring ensure that these modules can communicate effectively with the ECM and other components, leading to a more cohesive and efficient engine operation.

Overall Engine Wiring

Finally, the 3335571 Wiring Brace contributes to the overall organization of the engine’s wiring system. By providing a structured framework for the wires, it helps reduce the risk of entanglement, which can complicate maintenance and repairs. This organized approach also simplifies the troubleshooting process, allowing engineers and mechanics to quickly identify and address any wiring issues that may arise.

Conclusion

The Cummins 3335571 Wiring Brace is a vital component for maintaining the integrity and efficiency of a truck’s electrical system. Its design and features ensure that wiring harnesses are securely supported and organized, reducing the risk of electrical faults and simplifying maintenance and troubleshooting. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Fundamentals of Vehicle Dynamics and Modelling, Bruce P. Minaker, John Wiley Sons, 2019.

↩ -

General Information, Bulletin Number 4021428, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.