This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

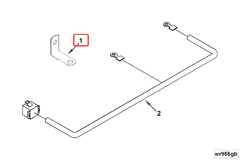

The 3356343 Tube Brace is a component designed by Cummins to enhance the structural integrity of heavy-duty trucks. This Cummins part is integral to maintaining the stability and durability of the vehicle under various operational conditions. Cummins, a well-established manufacturer in the automotive industry, is known for producing high-quality parts that contribute to the efficient and reliable performance of heavy-duty trucks.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle construction to reinforce the frame and chassis. Its general function is to provide additional support and stability, which helps in distributing loads more evenly across the vehicle’s structure. This reinforcement is particularly important in heavy-duty trucks, where the frame is subjected to significant stress from heavy loads and rough terrain. By enhancing the overall stability and durability, tube braces play a role in prolonging the vehicle’s lifespan and ensuring safer operation 1.

Purpose of the 3356343 Tube Brace

The 3356343 Tube Brace is specifically designed to offer structural support in heavy-duty trucks. It plays a role in reinforcing critical areas of the truck’s frame, which helps in maintaining the vehicle’s integrity under heavy loads and during rigorous use. This reinforcement contributes to the truck’s performance by ensuring that the frame remains stable and durable, which in turn supports the longevity of the vehicle.

Key Features

The 3356343 Tube Brace is characterized by several key features that set it apart from other tube braces. It is constructed from high-strength materials, ensuring durability and resistance to wear and tear. The design includes precise engineering to fit seamlessly with the truck’s frame, providing optimal support. Additionally, the brace may feature unique attributes such as corrosion-resistant coatings or specialized mounting points that enhance its functionality and ease of installation.

Benefits of Using the 3356343 Tube Brace

Incorporating the 3356343 Tube Brace into a heavy-duty truck offers several advantages. It improves load distribution across the frame, which reduces the risk of structural failure under heavy loads. The enhanced durability provided by the brace contributes to the overall longevity of the truck, potentially leading to cost savings over time by reducing the need for frequent repairs or replacements. Additionally, the improved structural integrity can enhance safety during operation 2.

Installation Process

Proper installation of the 3356343 Tube Brace is vital for ensuring optimal performance. The process involves several steps, including preparing the truck’s frame, aligning the brace with the designated mounting points, and securing it in place using the appropriate fasteners. Tools such as wrenches, drills, and measuring equipment may be required. Attention to detail during installation is important to ensure that the brace is correctly positioned and tightly secured, which is crucial for its effectiveness.

Troubleshooting Common Issues

Frequent problems associated with tube braces can include misalignment, loose fasteners, or damage from corrosion. For the 3356343 model, specific issues might arise from improper installation or exposure to harsh environmental conditions. Solutions involve realigning the brace, tightening or replacing fasteners, and applying protective coatings to prevent corrosion. Regular inspections and maintenance can help identify and address these issues promptly, ensuring the continued effectiveness of the brace.

Maintenance Recommendations

Regular inspection and maintenance of the 3356343 Tube Brace are important for ensuring its continued effectiveness and the overall safety of the truck. This includes checking for signs of wear, corrosion, or damage, and ensuring that all fasteners are tight and secure. Cleaning the brace and applying protective coatings as needed can help prevent corrosion and extend its lifespan. Following these maintenance guidelines can contribute to the reliable performance of the truck.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly renowned for its contributions to the heavy-duty truck sector. With a history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance, efficiency, and reliability of vehicles. The company’s reputation is built on its commitment to producing durable, high-performance parts that meet the demanding requirements of heavy-duty applications.

Tube Brace Part 3356343 in Cummins Engines

The Tube Brace part 3356343 is a critical component in the Cummins engine lineup, ensuring structural integrity and stability. This part is designed to support and secure the engine’s tubing, which is essential for maintaining the overall performance and longevity of the engine.

Application in Cummins Engines

-

4B3.9: The Tube Brace part 3356343 is integral to the 4B3.9 engine, providing necessary support to the engine’s tubing system. This ensures that the engine’s components remain aligned and secure, preventing any potential misalignment or damage that could occur due to vibrations or other stresses during operation.

-

Other Cummins Engines: While the 4B3.9 is specifically mentioned, the Tube Brace part 3356343 is also applicable to other Cummins engines. This part is engineered to fit seamlessly into various engine configurations, offering consistent support and reliability across different models.

The Tube Brace part 3356343 is a testament to Cummins’ commitment to quality and durability, ensuring that the engine’s tubing system remains robust and secure under all operating conditions.

Role of Part 3356343 Tube Brace in Engine Systems

Part 3356343 Tube Brace is instrumental in maintaining the structural integrity and optimal performance of various engine components. Its role can be observed in the following areas:

Accessories

The Tube Brace provides essential support for engine accessories, ensuring they remain securely in place during operation. This support is vital for accessories such as alternators, power steering pumps, and air conditioning compressors, which are subject to significant vibrational forces. By stabilizing these components, the Tube Brace helps maintain their efficiency and longevity.

Wiring

In engine systems, the wiring harness is often routed through or near the Tube Brace. This part acts as a protective guide, shielding the wiring from potential damage caused by moving parts or heat. It ensures that electrical connections remain intact and functional, which is essential for the reliable operation of the engine’s electronic systems.

Governor

The governor, a component used to regulate the speed of an engine, benefits from the stability provided by the Tube Brace. By securing the governor in place, the Tube Brace helps ensure consistent performance and prevents misalignment that could lead to inaccurate speed control. This is particularly important in engines where precise speed regulation is required.

Air Compressor

In systems where an air compressor is present, the Tube Brace plays a role in supporting this component. The air compressor, which generates pressurized air for various engine functions, experiences considerable stress during operation. The Tube Brace helps distribute this stress, reducing the likelihood of compressor failure and enhancing overall system reliability.

Conclusion

The 3356343 Tube Brace is a vital component in the maintenance and performance of heavy-duty trucks and Cummins engines. Its role in providing structural support, enhancing durability, and ensuring the stability of various engine components underscores its importance in the automotive industry. Proper installation, regular maintenance, and understanding its applications can lead to improved vehicle performance, safety, and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.