This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

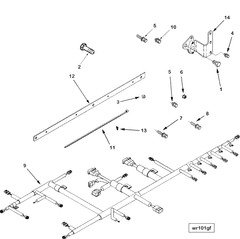

The Cummins 3609869 Wiring Brace is a component designed to support and organize the electrical wiring in commercial trucks. Its role is to ensure that the wiring remains secure and well-organized, which contributes to the efficient operation of the truck’s electrical system 1.

Purpose and Function

The primary purpose of this Cummins part is to support and organize the electrical wiring within a truck’s engine compartment. By securing the wiring in place, it helps prevent damage from vibrations and movement, which can otherwise lead to wear and tear on the wires. This organization also aids in maintaining a clear and accessible wiring layout, facilitating easier diagnosis and repair of electrical issues 2.

Key Features

This part is constructed with durability and functionality in mind. It is made from high-quality materials that can withstand the harsh conditions of a truck’s engine compartment. The design of the brace allows for efficient routing and securing of wires, reducing the risk of chafing or abrasion. Additionally, its robust construction ensures longevity and reliability in demanding environments 3.

Benefits

The use of the Cummins 3609869 Wiring Brace offers several benefits. It improves wire management by keeping wires neatly organized and secured, which reduces the likelihood of electrical faults. This organization also enhances the safety and reliability of the truck’s electrical system by minimizing the risk of short circuits and other wiring-related issues. Furthermore, it simplifies maintenance and troubleshooting by providing a clear and accessible wiring layout.

Installation Considerations

Proper installation of this part is crucial for its effective performance. Before installation, it is important to ensure that the engine compartment is clean and free of any debris that could interfere with the brace’s function. The necessary tools for installation typically include basic hand tools such as wrenches and screwdrivers. Following the manufacturer’s guidelines for installation will help ensure that the brace is securely mounted and that the wiring is properly routed and secured.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3609869 Wiring Brace involves periodic inspection to ensure that the wiring remains secure and undamaged. Cleaning the brace and the surrounding area can prevent the buildup of dirt and debris, which could otherwise lead to corrosion or other issues. If wiring problems are detected, such as frayed wires or loose connections, they should be addressed promptly to prevent further damage and ensure the continued reliability of the electrical system.

Compatibility and Usage

The Cummins 3609869 Wiring Brace is designed for use in specific types of trucks and engine models. It is commonly employed in various commercial truck settings where reliable and organized wiring is crucial. Its applicability extends to a range of Cummins engine models, enhancing the electrical system’s performance and durability in these applications.

Safety Precautions

When installing, maintaining, or troubleshooting the Cummins 3609869 Wiring Brace, it is important to observe several safety precautions. Electrical safety practices should be followed to avoid the risk of electric shock or other hazards. This includes ensuring that the truck’s battery is disconnected before working on the electrical system. Additionally, handling the brace and wiring with care will help prevent damage and ensure a safe working environment.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s product lineup includes a wide range of components designed to enhance the performance and reliability of commercial vehicles. The Cummins 3609869 Wiring Brace is one such component, reflecting the company’s commitment to quality and durability in automotive parts.

Wiring Brace (Part 3609869) in Cummins Engines

The Wiring Brace, identified by part number 3609869, is a critical component in the electrical system of Cummins engines, including the N14 CELECT PLUS. This part plays a pivotal role in securing and organizing the wiring harness within the engine compartment.

In the N14 CELECT PLUS engine, the Wiring Brace ensures that the electrical wiring is neatly arranged and protected from potential damage caused by engine vibrations and movement. It is typically mounted to a specific point on the engine block, providing a stable anchor for the wiring harness. This helps maintain the integrity of the electrical connections and prevents wear and tear on the wires, which could lead to malfunctions or failures.

The design of the Wiring Brace is such that it can accommodate various configurations of wiring harnesses, making it versatile for different engine setups. Its robust construction ensures that it can withstand the harsh conditions within the engine compartment, including heat and exposure to engine fluids.

For the N14 CELECT PLUS engine, the Wiring Brace is an essential part of the engine’s electrical infrastructure, contributing to the overall reliability and performance of the engine.

Role of Part 3609869 Wiring Brace in Engine Systems

The part 3609869 Wiring Brace is an essential component that ensures the secure and organized routing of electrical wiring within engine systems. Its primary function is to maintain the integrity and efficiency of the electrical connections by providing a stable and protected pathway for the wiring.

Integration with Harness

When integrated with the harness, the Wiring Brace plays a significant role in keeping the wiring neat and untangled. This organization is vital for preventing electrical shorts and ensuring that the harness can withstand the vibrations and movements inherent in engine operation. The brace helps in reducing the strain on individual wires, which can otherwise lead to breakage or intermittent connections.

Support for Electronic Control Module Wiring

In the context of electronic control module (ECM) wiring, the Wiring Brace is instrumental in safeguarding the sensitive electronic connections. The ECM relies on consistent and reliable data transmission through its wiring. The brace ensures that these wires are not only protected from physical damage but also from electromagnetic interference that could corrupt data signals. This protection is essential for the ECM to perform its functions accurately, such as monitoring engine performance and adjusting parameters in real-time.

Enhanced System Reliability

By securing the wiring, the Wiring Brace contributes to the overall reliability of the engine system. It ensures that all electrical components, from sensors to actuators, maintain a stable connection. This stability is particularly important in high-stress environments where engine systems are subjected to extreme temperatures, moisture, and mechanical stress. The brace helps in prolonging the lifespan of the wiring and reduces the likelihood of unexpected failures.

Facilitation of Maintenance and Diagnostics

The organized routing provided by the Wiring Brace also aids in maintenance and diagnostics. Technicians can more easily access and inspect the wiring, identify issues, and perform repairs. This accessibility is crucial during routine maintenance checks or when troubleshooting complex electrical problems. The brace simplifies the process of tracing wires and ensures that any modifications or additions to the wiring system can be implemented with minimal disruption.

Conclusion

In summary, the part 3609869 Wiring Brace is a fundamental component that enhances the functionality, reliability, and maintainability of engine systems by securing and organizing the wiring.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.