This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

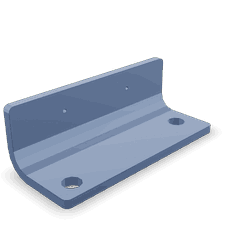

The Cummins 3627719 Wiring Brace is a component designed to enhance the electrical system of commercial trucks. Its purpose is to secure and organize the wiring harnesses, ensuring they remain in place and are protected from potential damage. This part plays a role in the engine cooling system by maintaining the integrity and efficiency of the truck’s electrical system, contributing to overall vehicle performance and reliability 1.

Purpose and Function

The Cummins 3627719 Wiring Brace serves a role in the electrical system by securing and organizing the wiring harnesses. It helps to keep the wires in an orderly manner, reducing the risk of tangling or abrasion. This organization is important for maintaining the electrical connections and ensuring that the system operates smoothly. By securing the harnesses, the brace also protects the wires from physical damage that could occur from vibrations or contact with other components 2.

Key Features

The Cummins 3627719 Wiring Brace is constructed with durability in mind, using materials that can withstand the harsh conditions often encountered in commercial trucking. Its design allows for easy installation, minimizing the time and effort required during maintenance or repairs. Additionally, the brace is compatible with specific wiring configurations, ensuring a proper fit and function within the truck’s electrical system 3.

Benefits

Incorporating the Cummins 3627719 Wiring Brace into a truck’s electrical system offers several benefits. It improves the organization of the wiring harnesses, making it easier to access and maintain the electrical components. This organization also reduces the risk of electrical faults that can arise from damaged or tangled wires. Furthermore, the brace enhances the durability of the electrical system by protecting the wires from physical damage, contributing to the overall reliability of the truck 4.

Installation Process

Installing the Cummins 3627719 Wiring Brace involves several steps to ensure proper integration into the truck’s electrical system. Begin by identifying the location where the brace will be installed, ensuring it aligns with the wiring harnesses. Secure the brace in place using the provided fasteners, making sure it is firmly attached to prevent movement. Finally, verify that the wiring harnesses are properly organized and protected by the brace, checking for any potential issues that may arise during operation.

Maintenance and Troubleshooting

To maintain the Cummins 3627719 Wiring Brace, regular inspections are recommended to ensure it remains securely installed and the wiring harnesses are in good condition. Common issues may include loose fasteners or damage to the brace itself. If any problems are identified, addressing them promptly can prevent more significant electrical issues. Troubleshooting steps may involve tightening fasteners, replacing damaged components, or reorganizing the wiring harnesses as needed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the commercial truck industry, providing reliable and efficient power solutions. The company’s commitment to innovation and quality has made it a trusted name among truck manufacturers and operators worldwide.

Compatibility with K38 and K50 Engines

The Cummins Wiring Brace part number 3627719 is designed to secure and stabilize wiring harnesses within the engine compartment. This part is important for maintaining the integrity of electrical connections and ensuring that wiring does not become damaged due to engine vibrations or movement.

K38 Engines

For the K38 engine series, the Wiring Brace 3627719 is specifically engineered to fit the unique layout and design of these engines. It is typically installed in areas where wiring harnesses are most susceptible to stress and movement. The brace helps to prevent chafing and potential electrical failures by keeping the wiring in a fixed position relative to the engine.

K50 Engines

Similarly, the K50 engine series benefits from the use of the Wiring Brace 3627719. Given the larger and more complex nature of the K50 engines, the brace is designed to accommodate the increased volume of wiring and the additional stress points that can occur. The installation of this part ensures that all wiring remains secure, reducing the risk of electrical issues that could lead to downtime or performance problems.

Grouping Considerations

Both the K38 and K50 engines share common design philosophies and engineering principles, which is why the Wiring Brace 3627719 can be used across these engine types. The commonality in design allows for a standardized approach to securing wiring harnesses, making maintenance and repairs more straightforward for technicians.

By using the same part number for both engine series, Cummins ensures that the installation process is consistent, and the part is readily available for use across different engine models. This standardization also aids in inventory management and reduces the likelihood of errors during part selection.

Role of Part 3627719 Wiring Brace in Engine Systems

The 3627719 Wiring Brace is a component in the orchestration of various engine systems, ensuring the seamless integration and operation of multiple components.

Integration with Accessories

The Wiring Brace facilitates the connection of various accessories to the engine’s electrical system. It provides a stable and secure platform for wiring, ensuring that accessories such as lights, sensors, and other peripherals receive a consistent and reliable power supply. This integration is vital for the proper functioning of these accessories, enhancing the overall performance and safety of the engine system.

Wiring Organization

In complex engine systems, the organization of wiring is paramount. The 3627719 Wiring Brace plays a role in this aspect by neatly routing and securing wires. This not only prevents potential short circuits but also simplifies the maintenance and troubleshooting processes. It ensures that wires are less prone to damage from vibrations or accidental contact, thereby enhancing the longevity and reliability of the engine’s electrical system.

Aftercooler Plumbing Support

The Wiring Brace also supports the aftercooler plumbing system. By providing a structured path for the wiring associated with the aftercooler, it ensures that the temperature regulation system operates efficiently. This support is important for maintaining optimal engine performance, especially in high-stress environments where temperature management is key.

Harness and Electronic Control Module Wiring

In conjunction with the mounting harness, the Wiring Brace plays a pivotal role in securing the electronic control module (ECM) wiring. This is essential for the ECM to communicate effectively with various engine components, ensuring precise control over engine operations. The brace ensures that the wiring remains intact and organized, which is fundamental for the ECM’s ability to monitor and adjust engine parameters in real-time.

Mounting Harness Functionality

Lastly, the Wiring Brace enhances the functionality of the mounting harness. By providing a robust framework, it allows the harness to be securely attached to the engine, reducing the risk of disconnection or damage. This is particularly important in dynamic environments where the engine is subject to various stresses and movements.

Conclusion

The Cummins 3627719 Wiring Brace is a key component in the intricate web of an engine’s electrical and mechanical systems. Its role in supporting, organizing, and securing various wiring and components is important for the efficient and reliable operation of the engine.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Giancarlo Genta and Lorenzo Morello, Springer, 2019

↩ -

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.